Soft Motors: The 3D Material That Changes Shape On Its Own

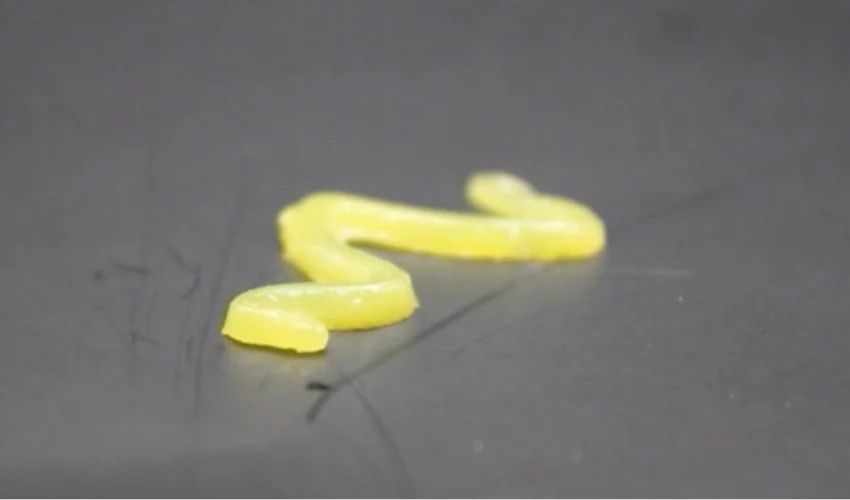

A team of researchers at Oregon State University, led by Devin Roach, has developed a revolutionary technique for 3D printing materials that can change shape. The material is programmed and once printed, it moves like muscles. These materials, known as liquid crystalline elastomers (LCEs), can transform key areas such as medicine, robotics and energy.

LCEs are polymers with a unique molecular structure that allows them to respond to external stimuli, such as heat, to transform into specific shapes. This behavior opens up new possibilities for devices that convert thermal energy into mechanical energy, which could be useful in advanced energy systems. For example, a device made of LCEs could capture energy from the sun and store it as mechanical energy for use on demand. In addition, LCEs offer solutions in the field of soft robotics. They can be used to create flexible machines capable of exploring environments that are dangerous or inaccessible to humans.

According to Roach, LCEs function as “soft motors,” making them ideal for applications in implantable medical devices. An example of their use would be the creation of stents capable of dynamically adapting to the body to release drugs in specific areas or to treat conditions such as incontinence using urethral implants. “Since they’re soft, unlike regular motors, they work great with our inherently soft bodies. So they can be used as implantable medical devices,” Roach explains.

The development of LCEs has required overcoming technical challenges. Roach and his team collaborated with institutions such as Harvard University, the University of Colorado, and Sandia and Lawrence Livermore national laboratories. Together, they found a way to align the molecules of these elastomers using a magnetic field and digital light processing (DLP). This method makes it possible to create objects layer by layer with precision, opening the door to complex structures that change shape with specific stimuli.

The team has also explored the use of LCE in mechanical damping, a crucial application for reducing vibrations in systems such as bridges, automobiles and buildings. Using the 3D printing method called direct ink writing, the researchers fabricated devices that dissipate energy efficiently, a point that demonstrates their versatility in multiple industries.

The work by Roach and colleagues, supported by the National Science Foundation and the U.S. Air Force Office of Scientific Research, lays the groundwork for a future where smart materials play a key role in advanced technology.

What do you think of the soft motors? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Oregon State University