SmartBuild Brings Stereolithography to an Industrial Scale

While stereolithography is a well-established additive manufacturing technology used by many, it comes with its share of challenges, particularly when it comes to scaling up. Manufacturers are often forced to make a difficult trade-off between speed and quality, while also dealing with complex and time-consuming post-processing steps and issues such as resin deformation. To address these challenges, Raplas Technologies has developed SmartBuild, a software solution designed for industrial stereolithography. The platform offers a range of features that make the process suitable for production needs, turning stereolithography into a truly scalable industrial manufacturing solution.

SmartBuild automates certain critical tasks and decision-making processes, making stereolithography more accessible without compromising on quality. The software includes a wide array of features that ensure full traceability and the level of automation needed to achieve maximum productivity. But what exactly are these features? And how does SmartBuild set itself apart from other solutions on the market?

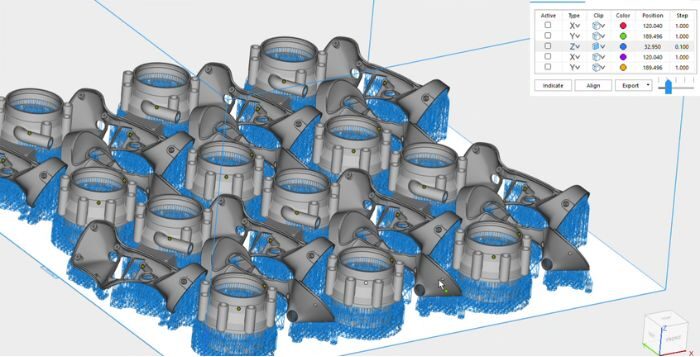

Example of 3D printed parts of a Raplas machine

SmartBuild Solves Key SLA Challenges

If you work with resin-based additive manufacturing, and stereolithography in particular, you have likely encountered several challenges. One of the most common is the trade-off between printing speed and part quality. Because the machine applies a single layer thickness across the entire build platform, users are often forced to choose between the two. SmartBuild eliminates this limitation through adaptive layering, enabling different layer thicknesses and layer styles within the same print.

The software also controls exposure at the level of individual areas of the part, helping to reduce issues related to resin shrinkage and, as a result, part deformation. Finally, SmartBuild significantly eases the post-processing stage, which is often both time- and labor-intensive. By producing near-polished surfaces, the software reduces the need for sanding and polishing, and in some cases eliminates these steps altogether.

SmartBuild offers a great number of features to ease the industrial SLA process

Features Designed to Automate Manufacturing

The software goes a step further by simplifying the printing process itself. More specifically, SmartBuild includes several tools designed to automate key manufacturing steps.

- Zone-based profiles and adaptive strategies: The software automatically identifies a part’s geometries and applies an optimized laser or projector path to each area. For example, curved surfaces are printed using ultra-thin layers to achieve greater precision.

- Physics and chemistry control: The generated structures use single-vector, single-pulse exposure, enabling highly precise control over the chemical and physical properties of the final parts.

- A simple interface: The goal is to provide operators with a comfortable, intuitive user experience, allowing them to start jobs with the push of a button. This approach also reduces the need for specialized expertise.

- Dynamic control: Rather than slicing the file into fixed layers before sending it to the machine, SmartBuild “negotiates” with the 3D printer in real time. It can rapidly select the optimal configuration while minimizing the need for support structures.

- Sustainability: SmartBuild can be added to Raplas machines going back a decade, and all new Raplas systems are built to support every upcoming software and technology enhancement.

What Are the Concrete Benefits of the Software?

Thanks to these features, SmartBuild delivers measurable results for manufacturers. According to Raplas, printing times are cut in half through tailored manufacturing strategies adapted to each project. Cost per part is also reduced, as resin consumption is optimized and post-processing time is significantly lowered.

Perhaps most notably, SmartBuild improves process repeatability. With predefined parameters and established profiles, operators can rely on a consistent and dependable solution without requiring specialized expertise. Last but not least, SmartBuild enables a quick and easy transition to mass production. Parts coming off the machine are nearly polished and can be used as end-use components. Raplas explains:

“SmartBuild signals a definitive shift toward software-defined manufacturing. It moves beyond black-box systems in favor of open, data-driven environments, allowing customers to remain competitive while enabling full digital integration. By providing the traceability and automation required for production, SmartBuild allows 3D printers to be managed and treated like any other high-end, production-ready CNC machine on the shop floor.” If you want to know more about the solution, you can contact Raplas experts HERE.

What do you think about SmartBuild? Have you ever tried it? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*Photo credits: Raplas Technologies