Skyrora and ESA Partner to Advance Europe’s 3D Printed Rocket Materials

UK-based rocket manufacturer Skyrora is spearheading a new European Space Agency (ESA) project that has the potential to redefine propulsion manufacturing. In collaboration with Metalysis and Thermo-Calc Solutions, the company is developing and 3D printing a new high-temperature alloy called Tanbium. The material itself is design to withstand intense conditions inside rocket engines while also cutting production costs and reducing Europe’s reliance on imported metals and other materials.

Tanbium was developed through the ESA’s General Support Technology Programme, and is specifically engineered to outperform traditional aerospace alloys such as C103 and IN718. By utilizing additive manufacturing, the new material offers up to 30 percent weight savings, increased temperature resistance, and longer burn times. Production through 3D printing also means up to 95 percent less material waste and a estimated 40 percent reduction in costs.

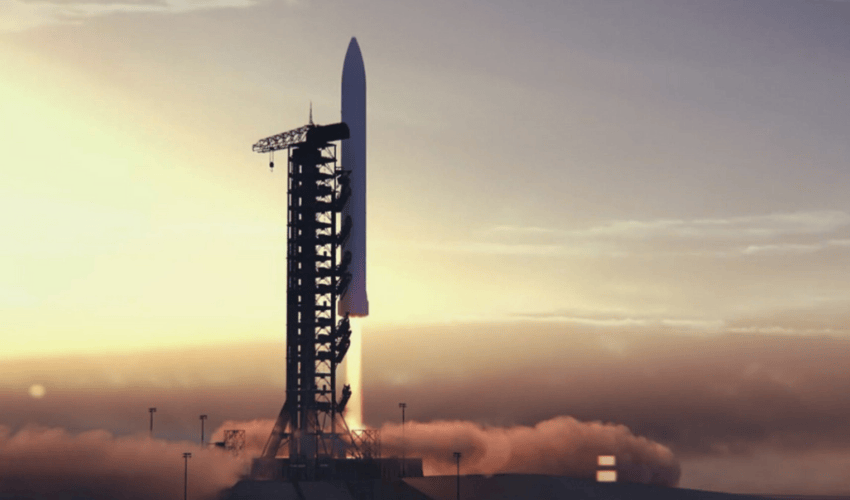

Tanbium represents a new class of high-temperature alloys developed for rocket engines, offering greater heat resistance and strength through advanced 3D printing techniques.

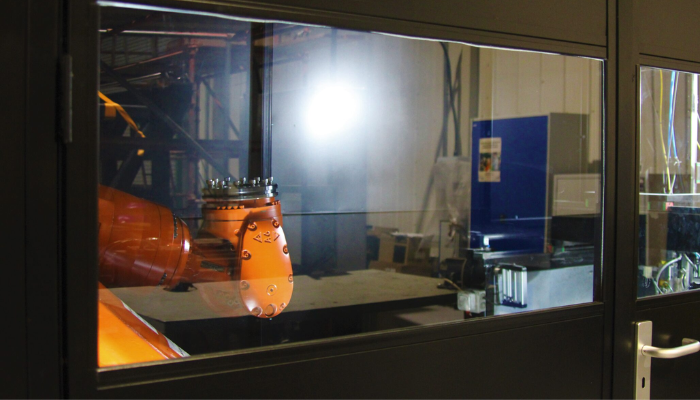

Skyrora will lead the implementation of the project using its Skyprint systems, including one of the largest Directed Energy Deposition (DED) 3D printers in Europe. The company’s Director of Buisness Development, Derek Harris, stated that the project reinforces Skyrora’s commitment to European self-reliance. He noted, “Tanbium will enable full domestic sourcing with the powder produced by Metalysis, components printed and tested by Skyrora, and performance optimised through Thermo-Calc simulation.”

The project’s technical team believes that Tanbium represents a major leap forward for propulsion materials. Ida Berglund, Managing Director at Thermo-Calc Solutions, said that the alloy “delivers performance and manufacturability gains that were previously out of reach,” which offers extended burn life and a significant cost reduction through its advanced design process.

Skyrora’s Skyprint system uses Directed Energy Deposition (DED) technology to produce complex metal components for next-generation propulsion systems with minimal material waste.

The ESA-backed initiative also supports sustainability goals by promoting low-carbon alloy production and localized supply chains. By using Metalysis’ proprietary solid-state process, the alloy powders are produced without the high emissions typical of traditional metallurgy. For the ESA, the project addresses a critical challenge in developing ultra-high-temperature materials for rocket motos and other applications.

If the project is successful, Tanbium could potentially pave the way for a new generation of efficient and lightweight rocket engines produced entirely within Europe. As of now though, Skyrora and its partner’s have combined advanced 3D printing with innovative materials science, not only improving engine performance but also reshaping how space hardware is designed and manufactured.

What do you think of this new partnership between Skyrora and ESA? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. For more 3D printing news in the aerospace and defense sectors, check out our dedicated page HERE.

*All Photo Credits: Skyrora