Six Metal 3D Printers Debuting at Formnext 2025

Every year, Formnext serves as a key moment for additive manufacturing companies to unveil their latest innovations, and this year is no different. Among the many announcements, we’ve seen a strong showing of new metal 3D printers, reflecting the continued shift toward industrial and end-use production in additive manufacturing. These new machines promise larger build volumes, higher throughput, and increased precision. Here, we’ve rounded up six metal 3D printers set to make their debut at the show, but we may see even more machines revealed once the event begins tomorrow.

The PROline from One Click Metal

Metal 3D printing solution provider One Click Metal is introducing PROline, a new series of systems built on the company’s core mission of making metal additive manufacturing more accessible and affordable. The PROline includes the MPRINTpro printing unit and the MPUREpro unpacking and sieving station. The MPRINTpro, which is an evolution of the company’s MPRINT, is designed for series production. It prints with a 500W laser, enabling reliable and fast production. Additionally, the MPRINTpro benefits from a self-cleaning filter system, developed with Herding Filtertechnik. This reduces run-time costs by running up to 500 hours without user interaction needed. The MPUREpro can then unpack parts quickly, with a vacuum moving powder through the automatic sieving station. Formnext visitors can see these machines at booth C101 in hall 12.0.

The new PROline series from One Click Metal

The Hammer Pro25 from Incus

The new Hammer Pro25 from Incus is engineered for 24/7 production. This machine can produce heavy-duty parts, as well as delicate geometries, empowering manufacturers to scale up AM. The Hammer Pro25 has a material throughput of up to 980 cm³/h, with automated material refill and finished part removal. It also has a build volume of 200 × 204.55 × 140 mm and flexible layer thicknesses between 10 and 100 μm. After sintering, these parts can have a high surface quality, sometimes even eliminating the need for post–processing. This solution is meant to allow manufacturers to move seamlessly from prototyping to the series production of metal parts. At Formnext, you can see the machine unveiled at booth E59 in Hall 11.1.

The Hammer Pro25

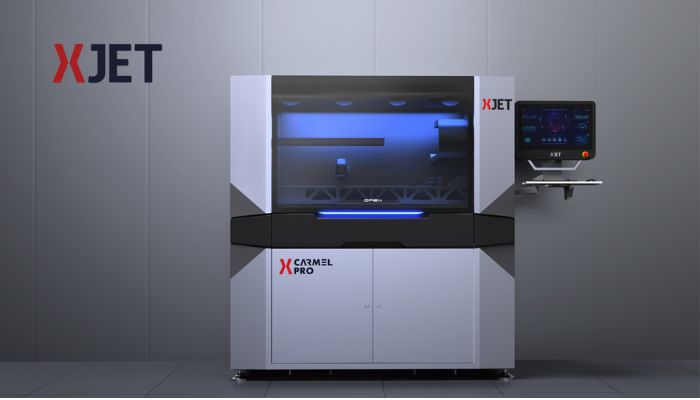

The Carmel Pro from XJet

The Carmel Pro from XJet is a little different from the other printers on this list, because it is capable of printing ceramics in addition to metal. The printer features a multi-channel print head configuration, which offers unique multi-material flexibility. Designed for SMEs, research centers, and premium jewelry manufacturers, the machine is a compact and cost-efficient solution. It employs NanoParticle Jetting™ (NPJ) technology, which entails the direct jetting of metal and ceramic inks with a separate soluble support material. This process is compatible with the entire XJet material portfolio, including precious metals, technical metals, and ceramics. Notably, the Carmel Pro has a 60-70% lower initial investment compared to XJet’s existing Carmel systems, creating an opportunity for organizations seeking to adopt metal and ceramic 3D printing for high-value end-use parts production. Visit the company at Formnext at booth D11 in Hall 11.0.

The Carmel Pro

The Print 300 and Print 400 from AltForm

AltForm, previously known as Prima Additive, will be debuting its new brand identity and new machines at Formnext 2025. Specifically, they’ll showcase the new Print 300 and Print 400, which are laser powder bed fusion machines engineered for industrial throughput, automation readiness, and tighter process control. The architecture of these printers introduces modular build chambers, enhanced gas-flow stability, redesigned thermal management, and improved multi-laser coordination. AltForm will also have the Print Genius 300 and a full ZENIT robotic cell equipped with Wire DED on display. You can visit AltForm’s booth E139 in Hall 12.0.

The Print Genuis 300

The TruPrint 5000 from ATLIX

Prima Additive is not the only company going through a rebrand: TRUMPF Additive Manufacturing is changing its name to ATLIX. At Formnext 2025, the German manufacturer will also be premiering its new flagship machine, the TruPrint 5000. The TruPrint 5000 offers a large build volume of 500 × 500 × 400 mm and four 1 kW lasers, making it ideal for large components and high-volume series production. With the multijob processing option, users can take full advantage of the machine, while automatic calibration and multilaser alignment ensure consistent precision. At Formnext, attendees can see the TruPrint 5000 at Hall 12.0, booth D99.

The TruPrint 5000

The FS721M-8-CAMS System from Farsoon and Brose

Farsoon Europe GmbH partnered up with Brose to produce a new metal 3D printer designed for the automotive industry. This printer is made entirely from recycled steel waste out of Brose’s press shops and is compatible with sustainable metal powder. The printer is based on the FS721M-8-CAMS system with a build volume of 720 x 420 x 390 mm³. The system is also available with an optional build volume height of 650 mm. The machine has eight lasers, making it great for efficient component production. At 8 x 2000 watts, the laser power is above the market standard. The printer employs Farsoon’s patented “beam shaping” technology, which allows for the high laser power to be used effectively. You can learn more about this technology at Hall 11.0, booth E11.

The Farsoon FS721M-8-CAMS metal 3D printer

What do you think of these new metal 3D printers? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*Cover Photo Credit: 3Dnatives