Singapore Strengthens Aerospace MRO with 3D Printing at Core

Singapore is advancing its position as a global aerospace hub with the launch of Phase Two of the Smart Manufacturing Joint Lab (SMJL), a partnership between the Agency for Science, Technology and Research (A*STAR), Rolls-Royce, and Singapore Aero Engine Services Private Limited (SAESL). The initiative aims to enhance maintenance, repair, and overhaul (MRO) operations by integrating advanced automation and additive manufacturing technologies.

The collaboration builds on the lab’s initial phase from 2017, which invested S$68 million to modernize Rolls-Royce’s fan blade production and optimize SAESL’s repair processes. That effort delivered measurable gains, including a 20 percent productivity increase at Rolls-Royce’s facility and projections of a 40 percent rise in SAESL’s output by 2028.

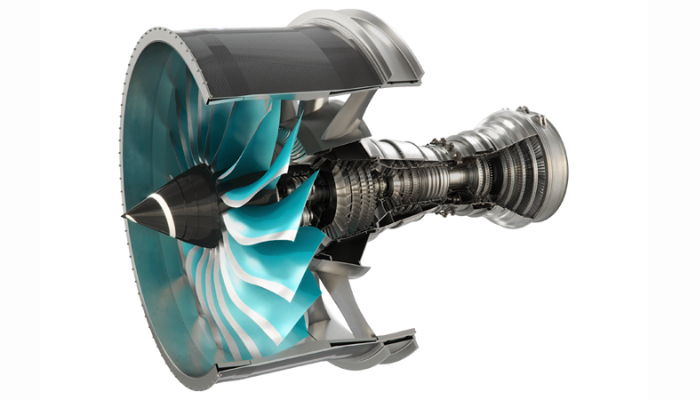

The Rolls-Royce UltraFan. (Photo Credit: Rolls-Royce)

A major focus of Phase Two is the adoption of 3D printing for component repair and engine overhaul. By integrating additive manufacturing into the MRO workflow, the partners aim to reduce lead times, minimize material waste, and improve the performance of complex parts. The upgraded processes are expected to help the Fan Blade Singapore facility boost production by over 30 percent without expanding its physical footprint.

The new phase complements SAESL’s S$242 million expansion at Seletar, which includes the construction of a 26,000-square-meter facility and the redevelopment of its existing space. Once complete, the project will double the company’s engine overhaul capacity to about 400 engines a year and create roughly 500 new jobs, further strengthening Singapore’s aerospace ecosystem.

A graphic showing SAESL’s expansion at Seletar. (Photo Credit: SAESL)

To ensure the consistent quality of 3D-printed components, Singapore also introduced a new national standard, SS 708, which is called: “Additive Manufacturing for Aerospace: Filament Layer Manufacturing Process Specifications.” This new standard establishes clear guidelines for safe and reliable additive manufacturing within the nation’s aviation and related sectors.

The SMJL initiative reflects a global trend toward digitally driven MRO operations, as aerospace manufacturers increasingly use 3D printing to improve efficiency and sustainability. Through this collaboration, Singapore is positioning itself at the forefront of next-generation aerospace manufacturing, combining innovation, precision, and smart production to support the industry’s future.

What do you think of this new development? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. For more 3D printing news in the aerospace and defense sectors, check out our dedicated page HERE.

*Cover Photo Credit: Singapore Agency for Science, Technology and Research