Silicone 3D Printing Allows for More Accurate Models of Blood Vessels in the Brain

At the University of Florida, a team of researchers is attempting to reproduce precise blood vessels in the brain using silicone 3D printing. To do this, they have developed a process called AMULIT, or additive manufacturing at ultra-low interfacial tension: this approach consists of printing silicone directly into a material bath. The latter acts as a printing medium and is, in this case, made of an emulsion of microdroplets of water in silicone oil. With this method, the researchers claim that they can design models of only four micrometers and thus reproduce very accurately the blood vessels in the brain.

Silicone has particularly interesting properties including biocompatibility, resistance to heat, chemicals and humidity. But it poses some challenges when it comes to 3D printing: it is a flexible material that cannot be resolidified once melted, unlike the filaments used in FDM/FFF. Therefore, silicone is usually printed in a liquid state before being irreversibly hardened. The difficulty also lies in the complexity of the shapes that can be created: how can we be sure that the structure will not collapse?

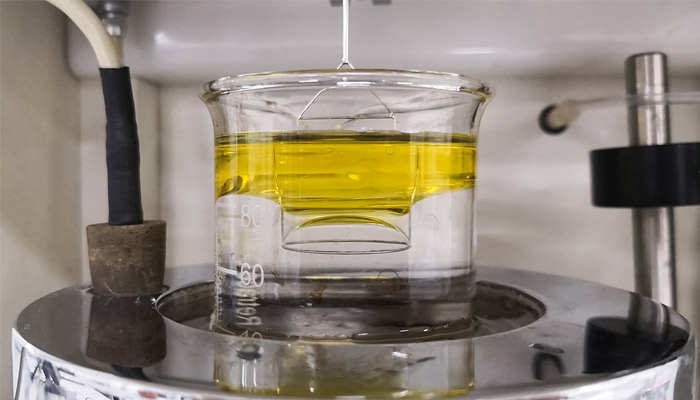

The researchers relied on the principle of interfacial tension (photo credits: Brighton Science)

An Innovative Silicone 3D Printing Process to Reproduce Blood Vessels in the Brain

To overcome these challenges, researchers have devised this bath printing process: the idea is to deposit successive layers of material by surrounding it with a silicone oil that acts as a support material. Why choose silicone as a support material? The team explains: “We decided to tackle the problem of interfacial tension by developing a support material made from silicone oil. We reasoned that most silicone inks would be chemically similar to our silicone support material, thus dramatically reducing interfacial tension, but also different enough to remain separated when put together for 3D printing. With our AMULIT support medium, we were able to print off-the-shelf silicone at high resolution, creating features as small as 8 micrometers (around 0.0003 inches) in diameter. The printed structures are as stretchy and durable as their traditionally molded counterparts.” Recall that interfacial tension is the force required to break the surface between two immiscible liquids.

Most of the support materials available on the market are water-based. However, silicone being an oil, when the two materials come into contact, deformations are created because, being immiscible, they need a high interfacial tension. Small drops of oil form in the water, impacting the 3D printed structure. That’s why the team came up with a silicone oil bath. The team adds, “We created many candidate support materials but found that the best approach was to make a dense emulsion of silicone oil and water. One can think about it like crystal clear mayonnaise, made from packed microdroplets of water in a continuum of silicone oil. We call this method additive manufacturing at ultra-low interfacial tension, or AMULIT.”

On the left, the material bath in which the silicone is deposited layer by layer as shown in the photo on the right (photo credits: Senthilkumar Duraivel/Angelini Lab, CC BY-ND)

The researchers’ first tests involve blood vessels in the human brain, which would allow neurosurgeons to train before an operation, to benefit from much more realistic simulations or simply to better understand the anatomy of a patient. They would be able to access physical models and touch these custom-made blood vessels, made from a 3D scan of the patient. We will keep you informed on the next developments of this team of researchers. In the meantime, you can read the entire study HERE.

What do you think about the use of silicone 3D printing to reproduce blood vessels in the brain? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.