Siemens manufactures the first 3D printed part for a nuclear power plant

For the first time ever, the German specialists in high technology, Siemens, has manufactured a 3D printed part for a nuclear power plant. A major challenge and accomplishment when taking into account the stringent safety and security requirements that comes hand in hand with a nuclear power plant.

Although this is new territory for Siemens, Siemens itself is no stranger to the 3D printing industry as they have continuously pushed themselves into the forefront of 3D printing. This can be seen with their latest innovations in the aviation industry, and their recent announcement of an additive manufacturing online platform. “We continue to push forward our investments and cutting-edge advancements in additive manufacturing and 3D printing,” Said Tim Holt, the CEO of Siemens Power Generation Services Division.

Siemens’ 3D printed spiders

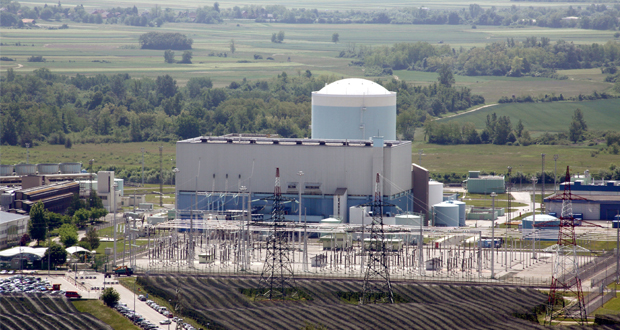

The nuclear power plant that received this 3D printed part is located in Krško, Slovenia and is considered one of the safest plants in Europe, according to the European Nuclear Safety Regulators Group. The part that will help the plant keep this title is a 108 mm in diameter impeller that will be in constant rotating operation. The pump will be used as apart of a fire protection system at the plant.

With the original manufacturer of this specific part no longer being in business, the plant had no other choice but to find another way to replace the part, which has been in use since the opening of the plant in 1981. 3D printing proved to be the most effective solution for the plant as it allowed them to print a part that matched the same specifications as the original model. Taking a digital format of the part, the Siemens team who were based in Sweden, was able to manufacture the part in question with ease.

From left to right: the original piece, the prototype and the final piece printed in 3D

“This achievement at the Krško nuclear power plant is another example of how the digital transformation and the data-driven capabilities we have are impacting the energy industry in ways that really matter,” explains Siemens’ Tom Holt. “Additive manufacturing’s reduced lead times and faster production optimizes parts replacement and creates real value for our customers.”

The most difficulty that the plant faced with this project laid in the fact that the plant has strict policies in terms of safety and quality. It was therefore necessary to ensure that the turbine that was 3D printed was reliable and that it met those requirements. Several tests were carried out with the operations team in Slovenia, as well as material tests. In the end, with the use of different 3D scans of the final piece, Siemens discovered that the material properties of the structure were higher than those of the original piece.

The Siemens factory is dedicated to additive manufacturing

“The better than expected performance of this 3D-printed part gave us confidence that we can reach the full life expectancy from our asset,” explains Vinko Planinc, the Head of Maintenance at the plan in Krško. “Siemens has a long history of innovation in this area and their dedication to providing their customers with the latest, proven innovations made them an excellent partner for this project.”

Siemens and the Krško plant have been working together for the last 10 years and are planning to continue their research work in 3D printing. Their goal is to create lightweight structures that are produced faster, with the same optimal levels of safety and quality.

What other ways do you think that 3D printing can serve nuclear power? Let us know in a comment below or on our Facebook and Twitter page!