Siemens’ AM Network helps companies adopt AM for industrial production

Adopting 3D printing in an industrial setting, specifically for mass production, is growing considerably. Nevertheless, some companies are still hesitant to invest in 3D printing technologies, as they can be unsure about the steps to adopt it successfully in their business. For this purpose, Siemens launched at the end of last year an online platform called AM Network. The company’s relationship with 3D printing actually began years ago, when it decided to invest in metal additive manufacturing by opening a center specialized in this type of production. Today, Siemens mission is to help companies accelerate AM mass production. There are many benefits to Siemens’ AM Network, to discuss, we met with its director, Robert Meshel.

3DN: Can you introduce yourself and tell us about your relationship with 3D printing?

I’m Robert Meshel, Director of the AM Network at Siemens. I am driven by a passion for technology and business innovation. I relentlessly pursuing new strategic opportunities to make a significant impact. Throughout my career I served in small startup companies as CEO and VP business development, as well as in various management capacities in large corporations in Strategy, business consulting, portfolio and product management. All in the manufacturing domain. Over the past 4 years I am serving as the Director of AM Network at Siemens. I hold an MSc in Mechanical engineering from Tel-Aviv University, an MBA from the Kellogg School of Business at Northwestern and a graduate of the Singularity University executive program.

Robert Meshel, Director of Siemens’ AM Network

3DN: Why did Siemens invest in AM technologies?

Siemens adopted AM as a Company Core Technology Field, one of five technology disciplines on which we invest significant amount in research and development. Siemens is involved with additive manufacturing in multiple capacities throughout its various businesses – as a user, service provider and technology provider. Siemens operates more than 100, mostly industrial grade machines. These are used across the various Siemens business units, where additive manufacturing is considered as a strategic technology.

Moreover, Siemens operates several service bureaus specialized in metal and polymer printing in highly regulated industries, such as Power Generation, Automotive, Aerospace, Mobility and Healthcare. These specialization and competencies put Siemens in a unique position to deliver engineering and consulting services for organizations that are looking to embrace digital transformation and leverage the AM technology as part of this process.

Additionally, Siemens is also a leader in end-to-end software automation and digitalization solutions for the AM industry. Its technologies are used within the new generation of high-end AM machines and enable the automation layer to build the industrial AM factories. The software solution suite enables building the Digital twins of the product, process and manufacturing facilities. It facilitates end-to-end workflow, covering product design and optimization, manufacturing definition and simulation, manufacturing execution and a full stack of IIoT solutions. The Siemens’ Additive Manufacturing Network is the new addition to the solution suite that extends our engineering software offerings to commercial and business processes workflow orchestration.

The Siemens Additive Manufacturing (AM) Network is the new addition to the solution suite.

3DN: Siemens launched the AM Network. What does it consist of?

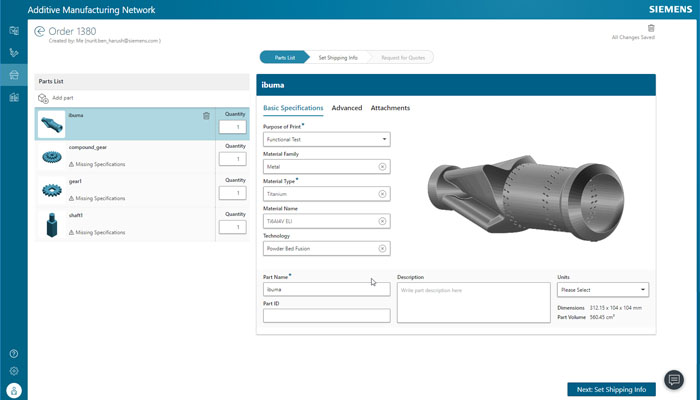

The AM Network’s roots were developed by a group of software developers and architects in a Hackathon that took place few years ago at our office in Tel-Aviv. Additive manufacturing drives a powerful transformation in manufacturing. It allows the rise of manufacturing as a service (MaaS) models, where manufacturing is consumed and delivered on-demand, by leveraging shared resources through a global network of certified suppliers. Siemens’ Additive Manufacturing Network is an online collaboration platform that is designed to streamline and digitalize the end-to-end “order to delivery” business processes for the industrial additive manufacturing community. It leverages three concepts to deliver the value to its users and partners:

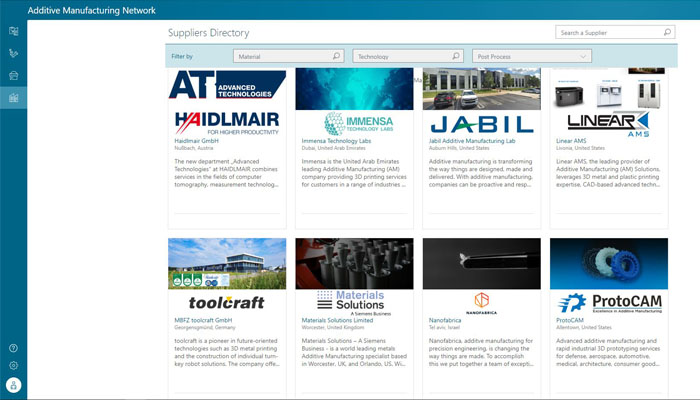

- Operate manufacturing-on-demand models, by facilitating an exclusive network of trusted partners, buyers and suppliers to drive a true manufacturing-as-a-service and manufacturing-on- demand business processes. That means you can get the parts you need, when you need, customized to your specifications, by leveraging an exclusive global supplier network.

- Facilitate collaboration and co-creation models across the organization functions, and throughout multiple organizations, to bring together the right competencies to get the job done.

- Provide a set of tools enabling workflow orchestration for the engineering, production management and the commercial tasks.

Siemens’ AM Network is a collaboration platform designed to streamline and digitalize the end-to-end business processes for the industrial additive manufacturing community

3DN: Why is the industrialization of AM driving demand for this sort of solution?

The science of additive manufacturing has progressed significantly over the past several years. Developments in material science and faster, more precise and reliable printers open new frontiers for innovation. Combined with the growth of supplier ecosystem, it is now possible to affordably produce a much broader range of things, often in much higher volumes. The industry is moving from limited applications to a central role in manufacturing for a growing number of industries.

Industrial additive manufacturing brings a great deal of opportunities to revolutionize the way products are designed and the way production is made. While numerous success stories of implementing AM in industrial grade application already exist, adaptation of industrial AM can be slow, as a result of the following factors: the increase demand for additive manufacturing services requires dedicated solutions to facilitate order submission, management and tracing. Secondly, the lack of knowledge and competency among the engineering community in using AM technology. Finally, customers expect prices to continue dropping, which demand suppliers to demonstrate higher operational efficiency in operating AM factories, to maintain profit levels.

3DN: What are the benefits of such a platform?

The AM Network platform from Siemens

Our customers are using the AM Network to engage with their suppliers. It helps them to organize all orders in one platform and keep the designers, procurement and the AM experts informed and synchronized about the order status and the interaction with the suppliers (e.g. proposals, messaging, quality reports etc.). it also allows them to streamline the order into production, so the process is fully digitalized. Siemens’ AM Network helps maximize the business potential for those using additive manufacturing – it streamlines the additive manufacturing processes, eliminates errors and exploits the full potential of digital manufacturing with less waste, fewer errors and revisions. It improves communication, planning and execution with an integrated AM system.

3DN: Who are Siemens’ AM Network customers?

Enterprises – these are entities that design and manufacture products and systems, and recently started using AM for their products and operations. This growing demand for AM is fulfilled by operating in-house AM production and leveraging instant access to a global network of suppliers to complement their production capacity. These entities are looking to increase engineering competencies in AM and to streamline disconnected functions, so that they can cut costs and create competitive advantage Such enterprises use AM in various of use cases such as rapid prototyping, on-demand tooling, digital warehouse for spare parts and more. Siemens’ AM network provides the functionality to support these use cases while uniting design engineers, production departments, procurement and other corporate entities on one integrated, one-stop system.

Siemens counts a number of customers from entreprises, service providers to partners

Service providers – these companies operate AM production and engineering services and are looking to boost business opportunities by making their services available to new potential customers, increase their order intake and provide enhanced and transparent service for their customers. They also require improving their operational efficiency through taking control over the order fulfillment process – from the order acquisition through production planning, scheduling, execution and reporting – with a single end-to-end solution. Siemens’ AM Network provides an integrated set of tools to streamline and automate the order to delivery functions.

Partners – these are the machine, material, software and engineering/ consulting services vendors. Siemens’ AM network allows them to get to market faster, expose new products to a larger audience and directly integrate into customers’ workflows. It provides access to tools and get the right experts on board to get the job done help instantly make the right analysis.

3DN: Do you have any last words for our readers?

My key takeaways over the past few years interacting with the AM industry are that additive manufacturing is a production technology, but it is also is a major transformational force for new business models. Its big impact will be realized, once these business models are realized. A big part of the use of AM is still bounded in prototyping and one-off productions. Industrialization of additive manufacturing is a key to extract the potential of this technology. And last but not least, AM is a complex, new technology. It requires knowledge in design, processes, materials, etc. Harnessing the ecosystem is a key to successfully leverage AM and build a true win-win for all industry stakeholders.

What do you think of Siemen’s AM Network? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!