Sicnova: Creators of the JCR 3D Printers

There are a variety of big players in the industrial 3D printer industry. These include 3D Systems, HP with their Multi Jet Fusion technology, and a number of others. However, is there an option in between desktop 3D printers, and large-scale industrial printers? We think we’ve found just that, with Spanish company Sicnova’s JCR 3D printers.

Sicnova 3D are based in Jaen, Spain, and are one of the leading 3D industrial printer manufacturers. With agreements with XYZPrinting, XponentialWorks, Techniplast and more, this Andalusian company is making good progress. Sicnova started in the 3D printing industry in 2006 when a collaborator discovered the potential of additive manufacturing through a television program.

Sicnova: JCR 3D Printer

After almost a decade as a ZCorp distributor, Sicnova became a distributor of 3D Systems printers. In 2014, the company decided they were looking to create a large new project. The first of these was a ‘Testing Laboratory’ where multiple 3D printing brands’ printers were tested. After testing these, Sicnova decided to add Ultimaker, Markforged, B9Creations, Shining 3D, and HP printers to their catalog.

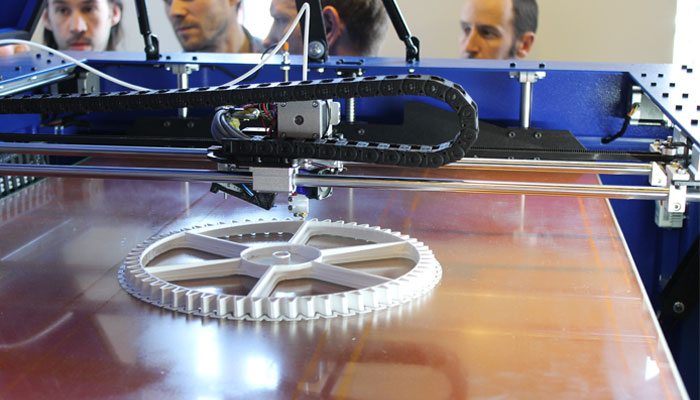

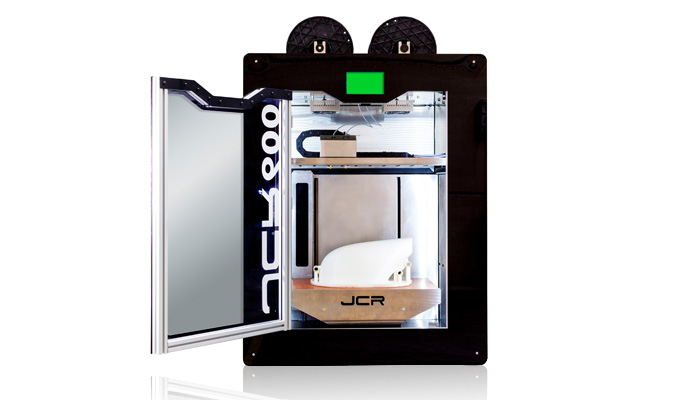

The second project was the creation of an R&D department. With their years of experience, Sicnova’s engineers had enough knowledge to start making their own 3D printers. Complying with needs that users had expressed, they created their JCR 3D printers. These industrial FDM 3D printers were affordable and still offered a great printing volume. The JCR 1000 has a printing volume of 1000x600x600 mm, and the JCR 600 has a printing volume of 580x400x500 mm. XYZPrinting chose both of these 3D printers to distribute under its brand.

The JCR 1000 3D printer.

“This line of 3D JCR printers has been evolving in what the customers are looking for in additive manufacturing: reliable machines, of large volume, with capacity to work with technical technicians, and able to work in the industrial industry for the manufacture of tooling, final pieces and rapid prototyping,” commented Sicnova’s CEO Ángel Llavero.

JCR: FDM 3D Printer

According to Sicnova, FDM technology will continue to dominate 3D printing. Therefore, Sicnova are focusing on creating materials for these 3D printers. It is expected that the development of technical materials will lead to far more options in 3D printing and additive manufacturing.

The JCR 600 3D printer.

The automotive, aeronautical and metal industries are the main beneficiaries of the JCR 3D printers’ techniques. This is because it’s applications are concentrated to tooling, manufacturing functional parts, and rapid prototyping. Sicnova 3D worked with brands such as Airbus, John Deer and Volkswagen in the creation of their printers.

Sicnova plans for future JCR 3D printers to remain FDM 3D printers, becoming more large format machines. They plan to specialise in the development of technical materials and hardware to upgrade the 3D printers’ reliability and stability.

Their large volume 3D printers have uses in sectors such as aerospace and automotives.

“We understand that machines like the Ultimaker cover niche from market to a little more low cost without subtracting quality, and we know that when you need to larger volume of pieces there are options like HP’s Multi Jet Fusion. We are in between the two, and create pieces of a certain size and quality that inspires confidence and we from Sicnova 3D aim to become that brand worldwide “, concluded Ángel Llavero.

You can check out their website here.

What do you think of Sicnova? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!