The State of 3D Printing 2017, the maturing 3D printing market

This week, 3D printing service company, Sculpteo, unveiled their third edition of “The State of 3D Printing 2017”. This report delves into the 3D printing industry, following the trends, strategies and insights, to see just how much the world of additive manufacturing has grown.

“Our annual State of 3D Printing is an opportunity for Sculpteo to collect data about the additive manufacturing industry. In this year’s edition, our principal aim is to give you the keys to understand what is at stake in this dynamic and rapidly evolving industry.”

More than 1,000 actors in the industry were surveyed for the report and were each divided into different categories. Once divided, they were left with the following results: 17% in consumer goods, 17% in industrial goods, 13% in high-tech, 9% in the service industry, 7% in the health sector, 6% in higher education, 4% in aeronautic and aerospace, 7% in electronic and electric, 5% in mechanic and metal, and 5% in automotive.

90% of respondents see 3D printing as a competitive advantage

One of the most noteworthy points of the report was that 47% of participants noticed a return on their investment in 3D printing, an increase from previous years. In addition, 90% believe that the use of this technology gives their business a competitive advantage, making it a vital part of its operations and manufacturing. With these conclusions, it is a sure sign of maturing within this market.

Respondents show less interest in buying a 3D printer, which means they still prefer to use external 3D printing services to produce and manufacture their products.

In relation to printing materials, the report found that plastic remains the most widely used material, with 88% of respondents using it. Followed by plastic, you have resins (35%), metals (28%), sand/powder multicolor (15%), ceramic (8%), and other (4%). In line with these results, FDM printing still remains the most popular choice with 36%. This is followed by Selective Laser Sintering, Stereolithography, Multijet/Polyjet, and Direct Metal Laser Sintering.

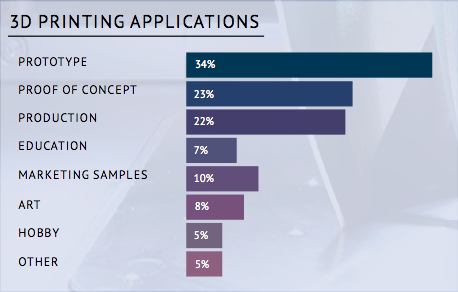

Main 3D printing applications

When focusing on metal 3D printing, the results concluded that Aluminum is the most recommended material with 62%, followed by stainless steel with 22%. The main appeals of 3D metal printing were cost reduction, the ability to produce small batches and complexity of designs.

When asked what level of skill respondents have in 3D printing, the results showed that 40% identified as being a beginner, followed by another 40% identifying as an intermediate. A key takeaway within the report shows that respondents feel that the lowering costs of the technology will have the biggest impact on the growth of 3D printing in the future.

“3D printing is a very innovative sector where technologies change fast. Comparing this year’s trends with last year’s results is a good way to understand the changes this industry is going through.”

Printing with FDM technology continues to hold the top spot

To read the full State of 3D Printing 2017 report, you can find it for free here.

Want to learn more about 3D printing? Follow us on Facebook and Twitter or sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!