The key to scaling up a 3D printing service: syncing engineering, sales and clients

In 2017, MakerOS, based between New York City and Detroit, launched its version 1.0 collaboration platform for digital fabrication companies. At the time, Mike Moceri, the startup’s founder, had realized from first-hand experience that dealing with multiple clients while managing the workflow of projects presented many efficiency challenges. Yet, no solution to meet these challenges existed on the market. As a result, he decided to develop a software that would allow fabrication and engineering service providers to centralize all their activities (communication, project submission, invoicing, etc.) in a unique centralised online portal. This central online portal is MakerOS. In September 2020, the startup announced the release of version 2.0 of their software platform. So, what is the value of syncing sales, engineering and clients when running a fabrication or engineering service? What benefits can you expect?

Increasing collaboration facilitates scaling up?

Almost all fabrication and engineering services have a process in place to receive new projects and a process to produce those projects. In the sales pipeline, a company will have a visual snapshot of where prospects are, showing the sales team how many deals they can expect to close in a given time period. These deals represent projects that need to be assigned to production. However, sales pipelines and production workflows are rarely synced, and a company might use two different software to keep track.

Therefore, if the sales team is looking for project updates, they will most likely need to ask someone from the engineering team directly or vice versa, which you can imagine, is not ideal. Additionally, pricing is tricky when these two teams are not working closely together, and mispricing becomes a common mistake in fabrication and engineering services, which can lead to losses in profit.

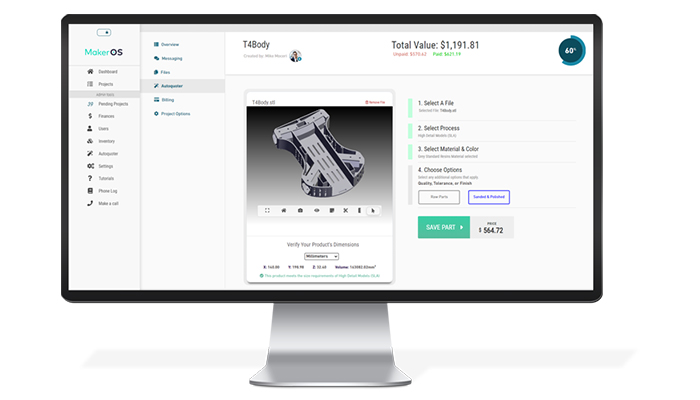

Recognizing these two common shortcomings is one thing, but what does the solution look like? The American startup decided to combine the sales pipeline and production workflow together and to develop an automated quoting process. They call these two solutions the Projects Board and the Autoquoter and both are available on MakerOS. On the Projects Board, a project’s status can be viewed by everyone in the company, including all respective files, messages, quotes and billing. All the project data is also collected by the Autoquoter, enabling an automated quoting process for most digital fabrication technologies. Subsequently, the engineering/production team is directly notified of the part that needs to be fabricated and the sales team can sell the part at the correct price.

Not all projects can be or should be ‘Autoquoted’. That is why MakerOS has included a custom invoicing system which allows services to add custom line items, services or stock products from the Product and Inventory Manager, and connect directly with a service’s QuickBooks online SKU’s.

Robert Lent, VP and Co-Founder at Vision Miner, a 3D printing distributor and service provider specializing in industrial-grade materials commented on the switch: “MakerOS has helped us organize everything, stay on top of client communication, and see the statistics of our service over time. It’s also increased the quality of how we process orders, which has translated directly to more orders being processed.” It is only logical that by saving time on order processing, a company can redirect these resources into taking in and completing new orders.

Another feature from the software is the Product and Inventory Manager solution. This allows a company to track everything and immediately know when it is low on parts and resources. The Product and Inventory Manager syncs with the Autoquoter too, so availability of resources is shared in real time and expectations are set accurately. If resources are low, the manager provides a link to reorder supplies directly from the platform. It is also possible to add services, machine operations/time, or anything else that may need to be charged to a client.

Lastly, MakerOS also now has a 3D File Viewer where you can view, manipulate, and annotate CAD formats, including SLDPRT, IGS, STEP, 3MF, 3DM, and more. Any CAD file uploaded can be converted into your preferred format including STL directly within a project’s file repository, which are all compatible with the MakerOS Autoquoter. There’s no more need to worry about client’s file formats and no need to continue using CAD software for the purpose of inspection and quoting with an expensive license of up to $12K per year.

Why include clients in your workflow?

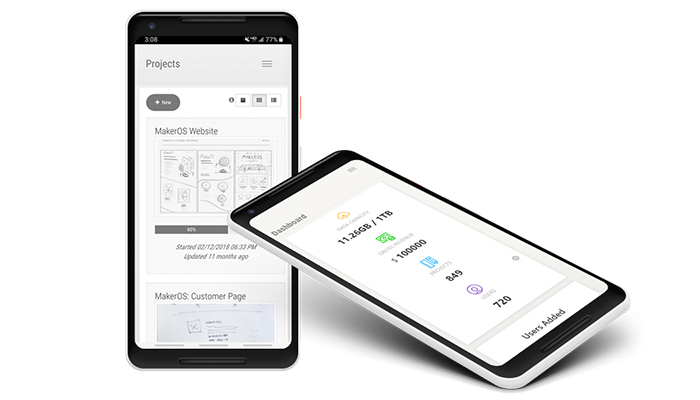

At this point, the following solutions will already facilitate fabrication and engineering companies’ activities tremendously, so why did MakerOS judge it was important to involve clients in the process even more so than with version 1.0? Indeed, with the release of MakerOS 2.0, the platform allows clients to be included in the project workflow at a higher level than before. The Client Portal which is accessible online allows your clients to access their projects, files, invoices, and send messages to your team very easily.

Instead of emails, the communication hub is where all messaging between the team and clients takes place. Project managers and their clients can attach CAD or any other types of files to their messages too, which are then stored inside the project’s file repository. Finally, the platform also acts as a project management tool by showing all project statuses in one place, as well as tracking project completion automatically and keeping clients in the loop. Of course, this leads to higher client satisfaction, which in the long-run is essential to generate more sales.

John Kray, CEO and Co-Founder of Hydra Research commented on the usefulness of the Client Portal: “Having a clean client project portal exudes professionalism and we have definitely noticed that it attracts more high-value clients to our business.”

If you’re curious about this solution, you can find much more information on the MakerOS official website. If you are also looking for more tips on starting a 3D printing service, you can watch our recorded webinar with Founder Mike Moceri HERE.

What do you think of the MakerOS platform? Let us know in a comment below or on our Facebook and Twitter page! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!