Safety in 3D Printing: What Protective Measures Need to Be Taken?

More and more companies are currently becoming aware of the enormous benefits of additive manufacturing and want to integrate 3D printing into their workflows in the future. Time and cost savings as well as increased design freedom in everything from the production of prototypes through to the most complex components are behind this move. However, not only large corporations, but also more and more private individuals are becoming increasingly enthusiastic about 3D printing and experimenting with different designs and materials at home. As tempting as it may seem to buy a 3D printer and print whatever you feel like, the reality is often different. Even though many 3D printers are described by the manufacturer as user-friendly, even experienced users can still make mistakes – which is why it is important to take a few precautions when 3D printing for your safety as well as others.

Whether in the form of filament, resin or powder, using a laser or UV light, proper use must always be observed for each material and process to avoid potential health hazards. In addition, it is particularly important when 3D printing to always be aware of what safety measures can be taken to protect yourself and those around you. In this article, you will learn about the potential risks of using a 3D printer and what measures you can take to maintain a safe 3D printing environment and protect your health.

Before Printing

First of all, we would like to draw your attention to a few steps that you can take before purchasing your 3D printer and before your first print. If you have decided to purchase a 3D printer, you can take the first safety measures before you buy the machine. In Europe, if the machine is marked with the familiar CE seal this means only that the printer meets the requirements of the applicable EU directives and may be sold within the member states of the European Union. Similarly in the UK you can find UKCA marking and UL in the US (though this is voluntary rather than a mandatory safety mark). Though this is not the end all be all of safety in 3D printing, these markings do suggest that the 3D printers correspond to certain basic standards.

The STOP Principle

Let’s now take a look at the general safety rules according to the STOP principle. This principle describes the sequence of protective measures to be observed and offers employers in particular, but also private individuals, support in the selection and ranking of measures, with each letter standing for a guideline.

The “S” here stands for substitution and draws attention to the choice of process and material. It is the most important and effective protective measure and should be considered first. It presupposes that any hazard should be replaced by a less harmful process or material in order to minimize the safety risk from the outset.

The next protective measure forms the “T” and stands for the technical protective measures. This includes three measures – the consideration of closed systems, the use of extraction systems and room ventilation.

The “O” stands for the organizational measures. These should be initiated if the protection goal cannot be achieved by either substitution or technical measures. Organizational measures can be, for example, rules on the shortest possible duration of stay to reduce exposure or the creation of operating and implementation instructions.

Finally, personal measures must be taken into account. These come last in the STOP hierarchy and must be observed if previous measures do not offer sufficient protection or by private individuals in the event of irregular and only occasional exposure. However, certain safety precautions depend on the process used and may vary accordingly. In the following, we present the potential risks of certain processes and materials and show you which technical, organizational and personal measures you can take.

During Printing

The various printing processes and materials each involve different risks that you should be aware of. In the following, we draw your attention to possible dangers and appropriate measures for 3D printing with filament, synthetic resin, powder and others.

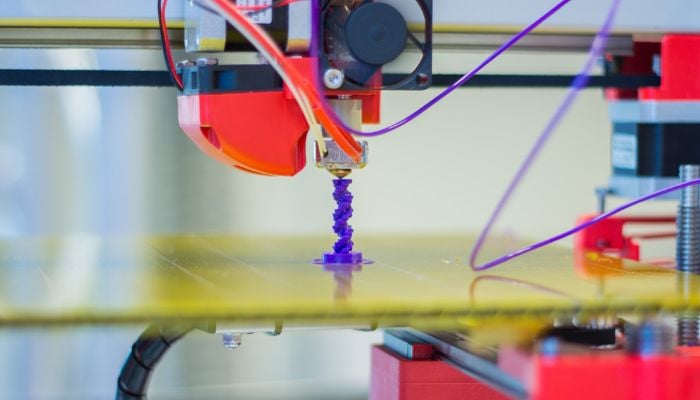

Using Filaments

According to the Hubs Report 2023, fused deposition modeling is the most popular printing process and more and more households and offices are relying on the use of FDM/FFF 3D printers in everyday life. However, even if 3D printing with filaments appears harmless at first glance, there are also health risks to consider with this process.

In a study by the UL Research Institute, the emissions generated by FDM/FFF 3D printing were examined and published in a “Guide to the safe use of 3D printing for universities, UL 200B”. The researchers found that small particles and volatile organic compounds, known as VOCs, are emitted during material extrusion. The ultra-fine particles and VOCs can act as a kind of gas, if inhaled they penetrate deep into the lungs and can enter the bloodstream and cause irritation to the eyes, nose and throat. This means that exposure can pose a risk to human health, especially if a person is standing next to the printer with minimal ventilation.

With regard to the different materials used in 3D printing with filaments, there are differences in the release of harmful substances. For example, it was found that ABS (acrylonitrile butadiene styrene) releases more toxic chemicals than PLA (polylactide), as it is made from petroleum, while PLA is considered a more natural material and is partly made from corn starch.

However, even if PLA is considered to be safer, additives are usually added to the material that release toxic chemicals such as styrene and chloromethyl when printed, substances that can irritate the respiratory tract, mucous membranes and eyes, as well as cause headaches and difficulty concentrating if inhaled directly. Still, the materials ABS, ASA (acrylic ester styrene acrylonitrile) and HIPS (high impact polystyrene), which is often used for support structures, were found to be the most harmful.

For this reason, care should be taken to ensure adequate protection when 3D printing with filaments of any material. When in operation, the printer should not be located in rooms such as the office or bedroom where you will be spending a long period of time. It is also advisable to choose a model with a closed printing chamber when purchasing the FDM printer.

The release of harmful substances is now known, so more and more manufacturers are producing printers with an integrated HEPA air purifier, a “high-efficiency particulate air filter”. Printers equipped with these functions in combination with adequate ventilation of the room usually offer sufficient protection. Nevertheless, it is advisable to avoid spending long periods of time in the vicinity of a working FDM printer and, if this is not possible, to wear an additional protective mask; an FFP2 or FFP3 mask is suitable for protection against particles.

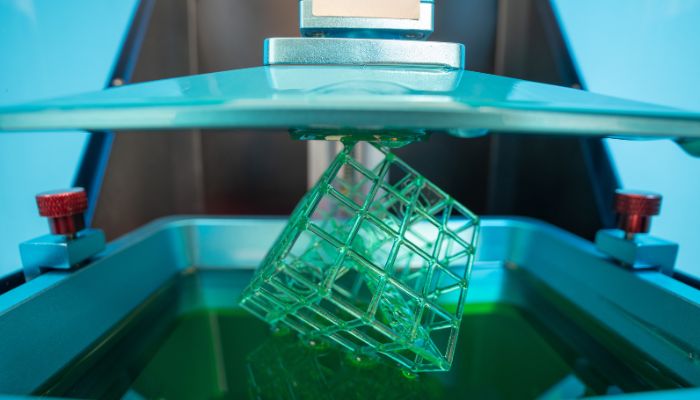

Safe 3D Printing Processes with Liquid Resins

However, it is not only in additive manufacturing with filaments that health measures must be observed. There are also some measures to consider with resin 3D printing for example in stereolithography (SLA), digital light processing (DLP), masked stereolithography (MSLA) and material jetting processes. Commercially available resin usually consists of mixtures of acrylic, epoxy and vinyl ether resins and can cause allergies and reactions on contact with the skin, especially with repeated exposure, which can become more severe over time.

In addition, the vapors released when the synthetic resin is printed can cause severe headaches, nausea and dizziness. Reactions of the eyes and mucous membranes can also occur. Conscious handling of the material is therefore essential. First of all, it is important to mention that the synthetic resin is only toxic in its liquid state. Once the component has hardened, it can be handled without any problems. If you are working with liquid resin, you should observe the following protective measures to ensure safe handling of the material.

Resins are toxic in a liquid state and should not come into contact with the skin

Ensure that you protect your skin with gloves and protective clothing. We recommend wearing nitrile or vinyl gloves for your hands. These offer more protection and have better chemical resistance than conventional latex gloves. Arms, legs and torso should also be fully covered and it may be advisable to wear a protective gown or disposable coverall. Chemical-resistant safety goggles are suitable for protecting your eyes, ideally also with integrated UV filter protection.

To prevent inhalation of the resin vapors, you should use an FFP2 or FFP3 mask. When using resins, photopolymerization takes place, i.e. the resin is cured using a light source, usually a UV light. When using some of these UV lamps, the gaseous hazardous substance ozone can be released, which can cause reactions in the eyes, nose, lungs and throat even at low concentrations. Ask the manufacturer about the potential release of ozone and, if necessary, install an extraction system with a suitable filter or ensure adequate ventilation.

Safer 3D Printing With Powders

Let’s continue with an important health risk that can occur when using Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), Directed Energy Deposition (DED) or Binder Jetting. These processes use powdered material, such as metal and plastic powder, and thus form particulate hazardous substances, i.e. dusts. The risk when working with powder depends on the size of the particles; larger powder particles are stopped in the throat by the body’s natural protective processes. Smaller particles, however, penetrate deeper into the lungs and are deposited in the alveoli; the dust particles can even enter the bloodstream. In this case, it is advisable to wear a respirator mask of filter class P2 or P3, which catches the fine particles.

Attention should also be paid to even ventilation of the room and proper extraction of the workplace. According to safety directive, power should be removed and cleaned “using damp or wet methods or with suitable vacuum cleaners or dust extractors” in order to avoid powder deposits.

Photo Credits: Additive Manufacturing Germany GmbH & Co. KG.

Other Risks to Take Into Account for Safe 3D Printing

In addition to the risks that may exist with the specific materials and processes, there are some dangers that should be taken into account in 3D printing in general. As already mentioned, 3D printers should always be operated in well-ventilated rooms where people do not spend long periods of time. It should also always be noted that 3D printers, such as FDM/FFF machines, operate at high temperatures of around 200 degrees and can therefore pose a risk of burns and fire.

Therefore, do not touch the nozzle or the print bed or the printer itself during and shortly after operation and do not reach into the print chamber, as movements of the extruder can lead to crushing and trapping of fingers and hands. Long hair should always be tied back and loose clothing should be avoided. Avoid leaving the 3D printer running unattended. Some manufacturers integrate cameras into the machines so that users can monitor the printing process remotely to prevent dangerous situations.

After Printing

Now you know the potential dangers of different 3D printing processes and materials and what protective measures you can take to ensure safe use before and during 3D printing. Now let’s move on to the final step after printing – the safe disposal of 3D printing materials.

Safe Disposal of 3D Printing Materials

As already mentioned, resins are toxic in liquid states and should not come into contact with the skin under any circumstances. For this reason, sufficient precautions should also be taken when disposing of resin. Resin left over from printing can be reused and poured back into the bottle. Resin that cannot be reused, as well as faulty objects, (pocket) cloths and used gloves that have come into contact with the material during the process, can generally be disposed of with household waste. However, care must always be taken to ensure that the synthetic resin has been fully cured in UV light before disposal, as the liquid resin can still release toxic substances and is also extremely harmful to the environment.

Filament can be recycled using special machines (photo credits: WEVOLVER)

Disposing of filaments, misprints and leftovers from FFF/FDM printing made from conventional plastics such as ABS, PLA and ASA or PET(G) is easier, however. When not in use, these can be cooled and disposed of safely in the yellow bag. However, it is advisable to collect the material and recycle it separately. You can do this yourself using suitable recycling equipment or commission specialized companies.

Now you know what risks the use of additive manufacturing processes and materials entails and what safety measures can be taken to protect yourself and your environment before, during and after the printing process.

What do you think of these protective measures for safe 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.