Ryan T. Watkins Talks DfAM for Better Spacecraft Performance at AMUG 2025

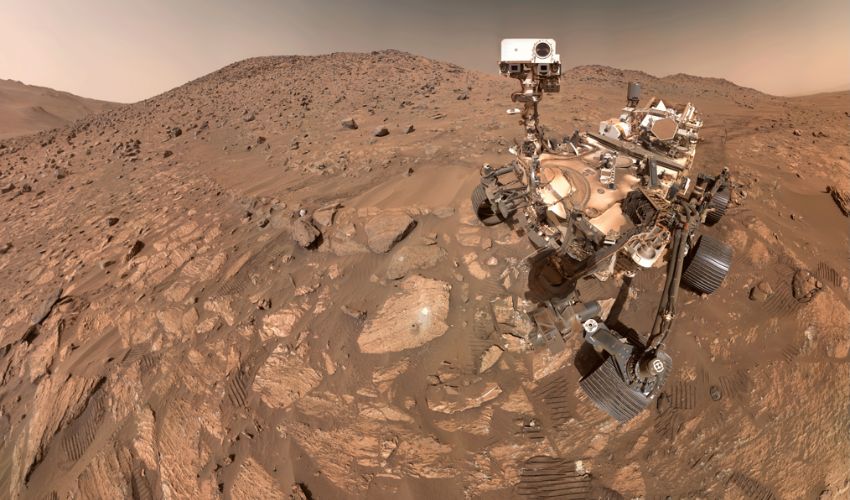

AMUG 2025 will be taking place soon on March 30 – April 3 in Chicago, Illinois. And one of the clear highlights is, as always, the keynote speeches, including one from Ryan T. Watkins, PhD, a research engineer at NASA JPL. He will be delving into the importance of design in additive manufacturing, especially as it relates to aerospace applications. We sat down with him to learn more about his work as well as what attendees can expect from AMUG.

3DN: Could you introduce yourself and your connection to 3D printing?

Ryan T. Watkins, PhD

My name is Ryan T. Watkins, PhD, and I’m a research engineer at NASA’s Jet Propulsion Laboratory in Pasadena, California. For nearly a decade, I’ve been exploring the possibilities of 3D printing and its impact on space exploration.

My research focuses on combining advanced manufacturing techniques, like additive manufacturing, with innovative design approaches such as topology optimization and lattice structures to enhance spacecraft performance. Beyond research, I help bring new technologies into space applications — for 3D printing, this includes qualifying materials for space environments, supporting teams in designing for additive manufacturing, and guiding the adoption of these techniques across missions.

3DN: What can we expect from your speech at AMUG?

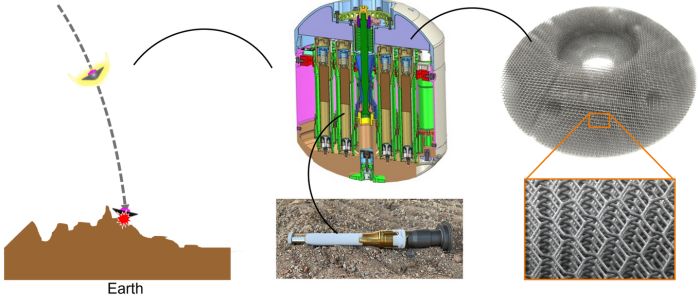

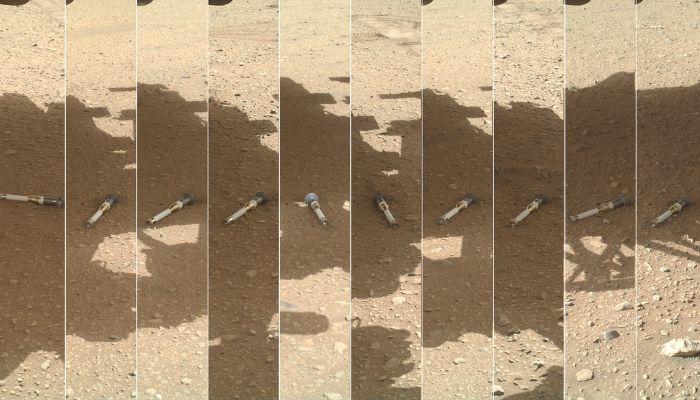

In my keynote speech at AMUG, I’ll share my work on 3D-printed titanium lattice structures developed at JPL for sample return missions. While lattice structures have long interested the additive manufacturing community, real-world adoption has been limited by design and fabrication challenges. At JPL, we’re leveraging these structures as energy attenuators to protect delicate samples during hard landings, such as on Earth’s surface.

As the principal investigator leading this research since 2020, I’ll discuss why crushable lattices are ideal for these applications, the R&D journey to develop and qualify them for flight, and the highs and lows of bringing a technology from concept to mission-ready.

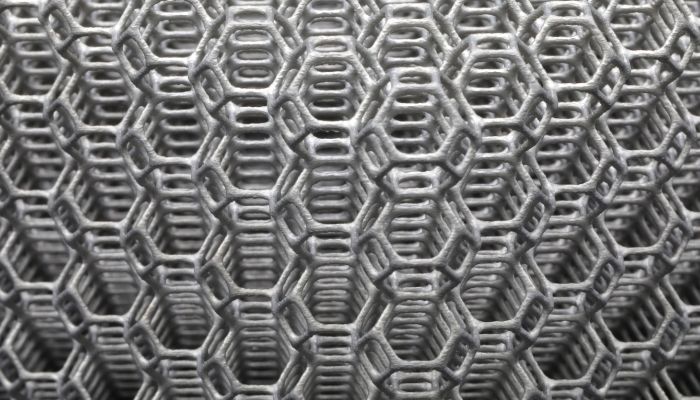

The crushable lattice concept that Dr. Watkins will be discussing at AMUG 2025

3DN: Why is it necessary to talk about the link between design with additive manufacturing?

For many engineers, our education and early career experience were grounded in traditional manufacturing methods, often before additive manufacturing became widely available. Even recent graduates sometimes have limited exposure to 3D printing, especially with metals. As a result, we often impose subconscious constraints on the design process — not just in shaping individual components but also in how we define engineering requirements.

This ingrained manufacturing intuition can unintentionally limit innovation, even when we try to break free from traditional thinking. Stepping into unfamiliar design spaces is difficult, which is why advancements in design tools are so critical. Tools like topology optimization help bridge this gap by shifting the design process from focusing on what a part should look like to defining what it needs to do.

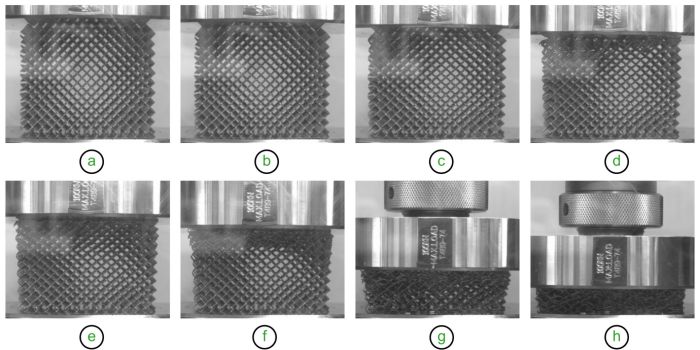

The lattices in the process of being crushed

3DN: What is the importance of events like AMUG for bringing different parts of the AM value chain, including design, together?

Engineering is often seen as a purely technical field, driven by logic, calculations, and precision. But the reality is that innovation, especially in additive manufacturing (AM), is equally shaped by human factors — our experiences, perceptions of risk, and the way we balance rapid technological change. These elements, though less tangible, play a significant role in determining the success of new technologies.

Events like AMUG are invaluable because they bring the entire AM community together, bridging the technical and human sides of progress. Beyond showcasing the latest advancements, these gatherings foster collaboration and shared understanding. They give us a space to connect, exchange perspectives, and navigate the social aspects of technology adoption. It’s this collective expertise and diverse outlook that have propelled 3D printing forward — and will continue to shape its future.

Examples of samples taken from Mars which would be protected by lattices such as those being investigated by Dr. Watkins

3DN: What are you most looking forward to at AMUG 2025?

Much of my experience with 3D printing has been concentrated in the aerospace sector, particularly for space applications. It’s easy to lose sight of just how widely this technology impacts other industries and disciplines. I’m looking forward to exploring these broader applications at AMUG 2025 and gaining new perspectives that might inform and enhance the work we do at NASA.

As JPL continues to expand its use of additive manufacturing, I’m also excited to see where the industry is heading — both in the near term and in the longer-term evolution of the technology. I’m especially interested in advancements in large-scale printing, as this is now becoming a limiting factor in many of our applications.

3DN: Any last words for our readers?

I believe additive manufacturing is at a pivotal point in its development. We now have a range of processes capable of producing high-quality, production-ready parts, and I’ve noticed a shift in the engineering community’s perception — from skepticism to genuine excitement.

A close up of some of the lattices designed by Dr. Watkins

The key question moving forward is whether the technology can evolve to make its value proposition even clearer. For instance, it’s not uncommon for complex parts to be cheaper to produce with 5-axis machining than with AM. If AM can close that gap while continuing to improve scale and resolution, manufacturing could look very different 20 years from now, especially in low-production industries like aerospace.

The potential is enormous, and how we navigate the next stage of development will shape the future of engineering and design.

What do you think of this interview with Dr. Ryan Watkins? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.