Rotating Nozzle Reduces Filament Waste in Color 3D Printing

Multicolor FDM 3D printing has gained in popularity thanks to innovative systems such as Bambu Lab’s AMS, which paved the way for a new generation of machines capable of handling multiple filaments simultaneously. This system, which quickly inspired other manufacturers including Anycubic and Creality, enables multicolored objects to be created with greater precision and ease. However, the process of changing filaments remains time-consuming and generates a considerable amount of material waste, particularly during the purging required to avoid undesirable color mixing.

Against this backdrop, Heinz Löpmeier has developed an innovative solution: a rotating nozzle capable of changing color without purging the filament, thus reducing waste and speeding up the printing process.

On his X account, Heinz Löpmeier shared the creation of his coaxial nozzle

An Innovative Concept: A Rotating Nozzle

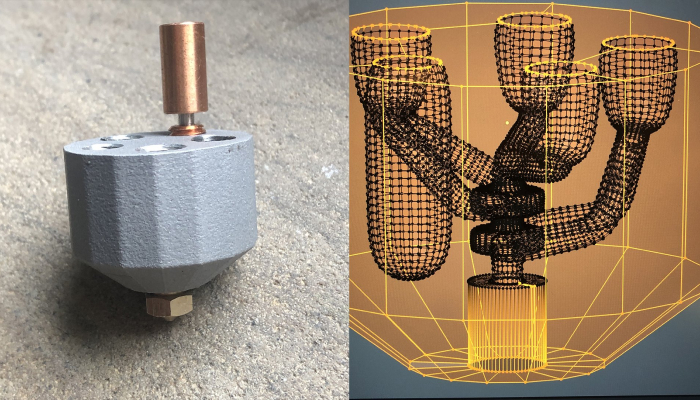

Heinz Löpmeier, known as “sophier” on Reddit, recently shared this innovation dubbed a “rotating mixing nozzle.” This nozzle, unlike the previously mentioned systems, doesn’t require color purging between changes, thus eliminating filament waste. The nozzle works using a Python script in Blender, also created by Heinz Löpmeier and published as open-source on GitHub, which associates specific colors with nozzle angles, enabling smooth color transitions and even “halftone” effects (for gradient effects).

The concept emerged after years of experimentation with standard mixing nozzles, which tend to create a “toothpaste” effect by not completely mixing filaments of different colors. Heinz Löpmeier first tried to control this effect using a printer whose platen could rotate to change color, but this approach proved too slow given the mass of the platen and 3D print to set in motion.

Instant color switching by rotating the nozzle.

All 3 colors are extruded at the same ratio. :^) pic.twitter.com/HaHDJEjkrB— Heinz Löpmeier (@nozzleboss) August 11, 2024

How Does It Work?

The operation of this rotating nozzle is relatively simple, but highly effective. When in action, the nozzle rotates to change the color of the extruded filament without altering the mixing proportions of the three filaments used. The script in Blender also enables subtle effects to be created by positioning the nozzle at a specific angle between two colors, producing prints with complex shades and gradients without the need for additional structures such as purge towers.

Heinz Löpmeier uses Marlin firmware, configured with an additional axis for nozzle rotation. One of the key innovations of this design is the ability of the Bowden tubes to twist and untwist during printhead movements, ensuring smooth operation and avoiding knots or jams.

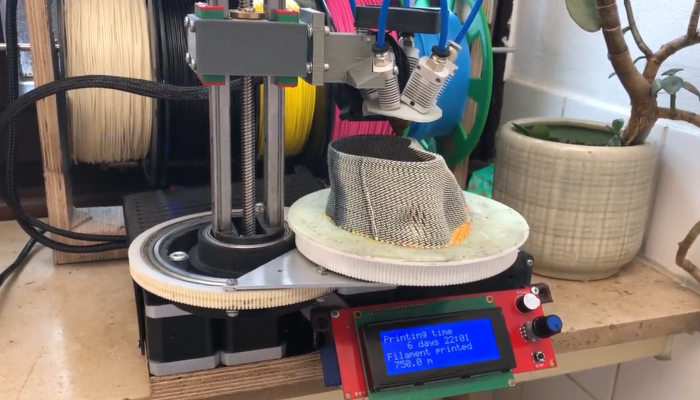

The previous prototype used the same process, but with a rotating table

A Powerful Tool for Creators

One of the major strengths of this system is its integration with Blender, a software package widely used for 3D modeling. Using Blender’s Python API, Heinz Löpmeier has developed an add-on called “nozzleboss”, which allows G-code paths to be manipulated directly within Blender. This opens up vast creative possibilities, allowing users to sculpt or paint modifications directly onto the tool path. What’s more, this approach eliminates the need for traditional slicing software, giving designers greater flexibility to customize their prints.

Heinz Löpmeier’s rotating nozzle could well mark a turning point in FDM 3D printing, particularly for those looking to minimize waste while exploiting the advantages of multi-material. Its innovative design, while potentially patent-worthy, has not yet been protected, opening the door for ambitious companies or individuals to turn it into a commercial product.

In addition to his rotary nozzle, Heinz Löpmeier uses non-planar 3D printing in his designs

However, Heinz Löpmeier himself seems unconcerned about this prospect, preferring to focus on innovation rather than intellectual property protection. This attitude contrasts sharply with recent patent disputes in the industry, notably between Stratasys and Bambu Lab.

With this rotating nozzle, Heinz Löpmeier offers not only a technical solution, but also a more sustainable and efficient vision of multi-material 3D printing. It remains to be seen how this technology will evolve, and whether it will be adopted by the wider community of makers and 3D printing professionals. For more information on the project, check out Heinz Löpmeier’s Reddit post HERE.

What do you think of Heinz Löpmeier’s innovation? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Heinz Löpmeier