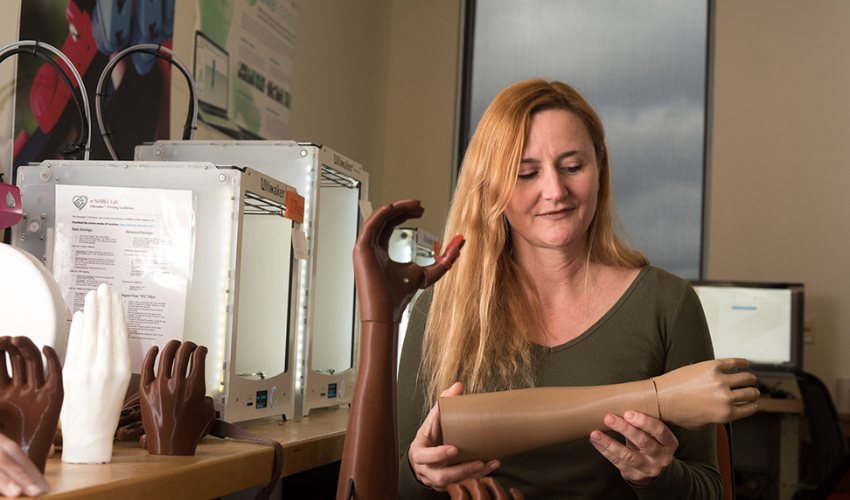

RIT Professor’s 3D Printing Initiative Offers Hope to Amputees

Fueled by 3D printing’s potential to create customized and complex structures, the field of prosthetics has undergone a major transformation in recent years, offering life-changing solutions to individuals with limb differences and amputations. One of the leading figures at the forefront of this movement is Professor Jade Myers at the Rochester Institute of Technology (RIT). Through her pioneering work, which has leveraged the precision and adaptability of 3D printing, she has brought renewed hope and mobility to those facing limb loss worldwide, particularly in conflict zones and areas struck by natural disasters.

Myers, whose journey into 3D printed prosthetics began in 2015, has been leading efforts to adopt this cutting-edge technology for the benefit of amputees worldwide. Through her involvement with RIT 3D printing initiatives, Myers soon recognized the immense potential of using 3D printing to produce high-quality prosthetic limbs.

3D printed “Designer Bodies I” prosthetic by Professor Jade Myers. (Photo Credit: Jade Myers)

By employing computer-aided design, 3D printing enables unparalleled customization, ensuring prosthetics are uniquely tailored to the needs and preferences of each individual. Moreover, the use of lightweight materials not only facilitates a personalized fit but also enhances comfort at significantly reduced costs. Another crucial advantage lies in the technology’s mobility, as these printers can be easily transported to reach patients in remote or inaccessible areas, allowing for on-demand production of prosthetics within a matter of hours.

In 2017, Myers came to lead a team in Haiti following the devasting earthquake, which left many individuals needing amputation. Utilizing their portable 3D printers and 3D scanners, Myer and her team were able to provide on-the-spot prosthetic fittings, bypassing logistical challenges and significantly reducing the time and costs associated with traditional prosthetic production.

This capability has been particularly critical in Haiti, where the rate of amputations and individuals facing limb loss is among the highest in the world. Speaking on their efforts, Myers stated, “In Haiti, it is very hard for a person to not only afford a prosthesis, but to get to a clinic. Some people spend the night outside of the clinic waiting for them to create this device, which takes several days for them to make. The faster it happens, the sooner people can have the opportunity to wear these. It not only impacts them but can also have a ripple effect on families and their opportunities.”

Jade Myers with friend and beneficiary of 3D printed prosthetics, Danie Exilus. (Photo Credit: Jade Myers)

Currently, over 30 individuals in Haiti are fitted with the 3D printed prosthetic limbs. However, the impact of Myers’ work extends far beyond the country. Through collaborations with non-profit organizations and medical professionals, she has introduced the concept of 3D printed prosthetics to communities in South Africa, Jordan, and beyond to assist in humanitarian crises. With advancements in materials science, design optimization, and accessibility, she envisions a world where individuals of all backgrounds can access life-changing prosthetic solutions. Notably, last spring, Myers was awarded the institute’s 2023 Bruce R. James ’64 Distinguished Public Service Award in recognition of her work to provide low-cost prostheses to those in low-resource areas.

What do you think of these efforts to make 3D printed prosthetics more accessible? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Rochester Institute of Technology