Revo Foods’ 3D Food Printing Hits the Industrial Stage

Sushi, fish dishes, and seafood continue to be popular on our plates, even in regions without direct access to the sea, where these goods are imported. However, this regional demand has taken a toll on our oceans, with approximately 90% of fish species dangerously close to the exploitation limit and 30% already overfished. Despite these alarming statistics, the 400 billion dollar fish market remains largely indifferent, and consumer satisfaction continues to contribute to the depletion of fish stocks.

In a promising move to counter this concerning trend in the fish market, the food tech startup Revo Foods is targeting the power of 3D printing technology. Established in 2021, the company utilizes 3D printing to create plant-based fish alternatives as a response to overfishing and the exploitation of fish species. In September 2023, Revo Foods successfully introduced its first commercially available product, “The Filet – Inspired by Salmon,” which is made out of 3D printed mycoprotein. The product quickly sold out within 48 hours, highlighting a significant demand for sustainable alternatives. Now, the company is responding to this overwhelming interest by announcing the company’s next big step: production at an industrial level.

Revo Foods Looks to Produce 3D Printed Fish On An Industrial Scale

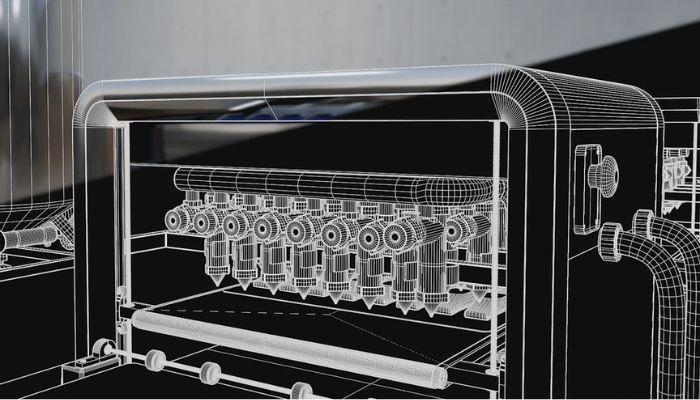

To elevate its production capabilities, Revo Foods has created a production method that enables 3D food printing on an industrial scale. The Revo Foods Fabricator X2 3D printing system represents a groundbreaking advancement, marking the world’s first large-scale production of 3D printed plant-based fish alternatives. The Fabricator X2 utilizes an advanced printing process, incorporating a high-precision extrusion system equipped with multiple nozzles. This multi-nozzle system ensures continuous printing while allowing for the combination of different materials. As a result, the 3D printing process makes it possible to create any shape and composition.

This technological leap opens the door to the development of entirely new product categories. The system’s adaptability allows for the manufacturing of different products within the same system without need for significant hardware modifications.

The next upscaling step is to take place with the Revo FFX2 3D printing system.

As many of us have experienced, we often eat with our eyes, as the visual appeal of food plays a crucial role in our overall dining experience. However, the Revo Foods printing process within the Revo Food Fabricator X2 extends beyond merely shaping various visual elements. Beyond offering diverse shapes, this 3D printing process has the unique capability to influence both the structure and texture of the products.

One breakthrough lies in the embedding of fats within plant protein fibers—a feat not previously achievable in any other 3D printing method. This development holds particular significance in the creation of authentic plant-based meat alternatives that stand on par with their animal counterparts in terms of structure, texture, and visual appearance.

“3D food printing on an industrial level allows us to change the way we think about food. Products that were previously very exclusive and more likely to be found in gourmet restaurants can now be produced on a large scale,” explains Dr Robin Simsa, CEO of Revo Foods.

The creative exploitation of almost endless potential could therefore lead to numerous innovations in food production without wasting food. Leveraging 3D printing in smaller batch productions and on-demand processes ensures the efficient use of resources, aligning seamlessly with Revo Foods’ commitment to sustainability—an aspect that resonates strongly with consumers.

In light of this, Revo Foods aims to amplify its production capacity in the coming two years through two strategic upscaling phases, ultimately reaching an industrial scale. Recognizing the need for support for this venture, Revo Foods has initiated its first public investment opportunity. The company invites interested parties to participate in this project through the green tech investment platform FunderNation. Investors have the chance to contribute to scaling up and expanding production capacity, with the investment opportunity available until April 18, 2024. To learn more, click here.

What do you think of Revo Food’s plans to expand 3D food printing to an industrial scale? Would you switch from traditional seafood to the 3D printed alternative? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Revo Foods