REV3RD on its Solutions for Sustainable, Large Format 3D Printing

Large-format 3D printing is one of the trends the industry has seen in recent years that promises to revolutionize the way companies produce large-scale products. Its accuracy, speed and versatility make 3D printing an ideal solution for large-scale product production. We delved more into this topic in our interview with Alessandro Torre, founder and CEO of Italian company REV3RD, which develops solutions for large-scale additive manufacturing all while keeping sustainability in mind.

3DN: Could you introduce yourself and your connection to 3D printing?

3DN: Could you introduce yourself and your connection to 3D printing?

Hello ! My name is Alessandro Torre, born in Bologna and raised in Puglia to the sound of orecchiette and tortellini! My interest in the world of 3D printing started during my years of study in mechanical engineering in Milan, when the idea of making a tool capable of giving shape to the most extravagant engineering ideas with little money led me to turn my room into a small workshop where I could build my first printers. More than academic textbooks, online forums and the “open source” philosophy were the main sources to start this 3D journey. Over the years, I continued to cultivate this passion, until I founded REV3RD, my second experience as an entrepreneur in this field.

3DN: How did REV3RD come to be?

REV3RD is an innovative startup focused on designing and manufacturing large format 3D printing solutions. It was born in early 2020, shortly before the pandemic emerged, after winning the regional PIN call for young entrepreneurs with innovative ideas. Unlike the brain drain that leaves the south, and very often Italy, we wanted to try this path in our territory by creating an international reality here in Puglia. Our main objective? To build the biggest and most innovative extruders in the world!

3DN: Could tell us about REV3RD’s large format 3D printing technology?

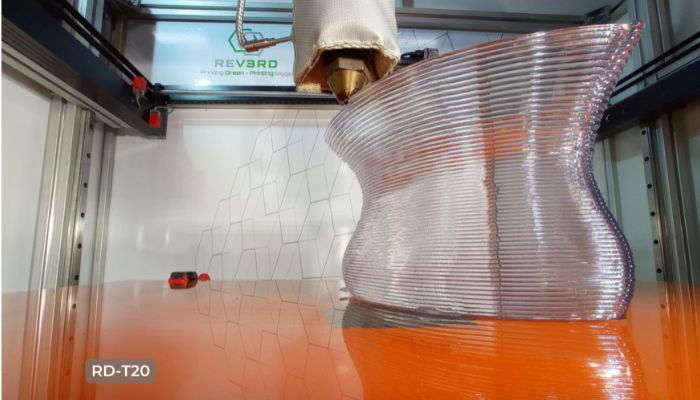

We like to think big! The first step was to design, screw by screw, a 1x1m printer. However, we needed to focus on extruders that were not limited in terms of the amount of material extruded over time. This is how the RD-M10+ extruder was born, which deposits up to 12 kg/h, then the RD-M25 and finally the RD-M40 capable of extruding up to 40 kg/h. The advantage of using this type of extruder is that it can be mounted on existing gantry machines or robotic arms and can be designed and customized in terms of weight, power, materials to be processed, dimensions and sensors.

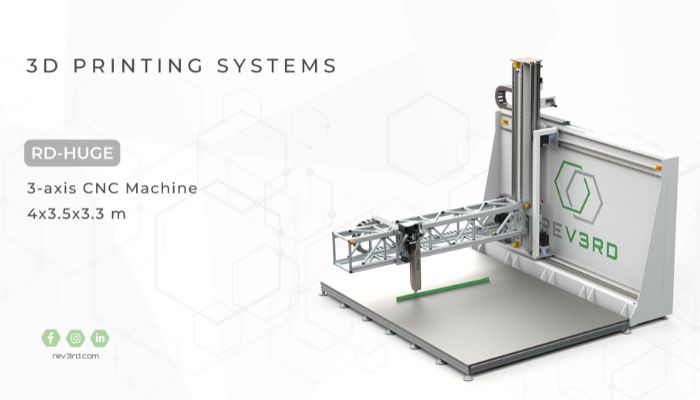

Finally, we have created the RD-HUGE, a printer with a working area of about 3×2.5m that allows us to test large formats. It is a Cartesian 3-axis machine with a cantilever arm that can be used for different applications in various sectors: in the art sector for the production of furniture elements, sculptures or film sets; in the automotive and energy sectors for the production of molds for the creation of carbon fiber laminated parts; finally, sectors such as aerospace, shipping and maritime transport are also very interested in this machine.

One of REV3RD’s solutions

Everything is designed in-house. As in any startup, there are many sleepless nights, but for us, the important thing is to keep growing!

3DN: What materials are compatible with RV3RD pellet extruders?

Our extruders can process virgin and recycled and/or recyclable polymers, standard or high performance thermoplastics and even fiber filled (e.g. ABS + carbon or glass fiber). We have also filed a patent on continuous fiber co-extrusion… Stay tuned !

3DN: How important is automation of production systems in 3D printing?

The development of automation systems in 3D printing is a very interesting topic for optimizing production processes and obtaining a better return on investment by those who rely on this technology. For now, 3D printing is still at a TRL (Technology Readiness Level) of 6, but more complete automation could increase this parameter. If the goal is mass production of variable geometry products, what is still missing in the process are sensors and control parameters that can bring the deposition process closer to the “perfect synergy” of human body movement and control. This is why REV3RD invests in the development, monitoring and control of the printing process.

3DN: What do you think are the main advantages and disadvantages of 3D printing with a robotic arm?

A robotic arm is a mechanical system that has already been used for years in different sectors, such as welding or painting. It is therefore easy to find, even at relatively low prices, given its widespread use. In addition, the control of 6 or more degrees of freedom allows for greater flexibility of movement. However, it still generates some control headaches, a problem that is less of an issue with Cartesian machines. Another disadvantage of robotic arms is that they are certainly less accurate systems if dimensional tolerances with high material removal are desired.

REV3RD uses a robotic arm in its systems

3DN: How is REV3RD addressing sustainability and the circular economy?

REV3RD (read Reverd) has these issues at heart: the Italian word “verde” (green) and the idea of circularity given by the English prefix “Re-” form the name and spirit of our brand. We believe that 3D printing and sustainability are complementary for two main reasons: first, additive manufacturing is itself a more sustainable production process than traditional subtractive manufacturing processes; waste is significantly reduced because 3D printing only deposits the material needed to make an object. This is a significant advantage. In addition, the ability to print an object with recycled and recyclable materials is an added value in today’s world of pollution, waste disposal and waste. If eliminating plastic from the planet is a utopia, recycling it and giving it a new life through 3D printing is a real possibility.

3DN: Any last words for our readers?

We will continue to refine the products we market with new features. To do this, we plan to hire new talent and build a production, testing, research, experimentation space… We expect a lot of work on the horizon, a lot of new things coming up! You can find more information HERE!

What do you think of the solutions developed by REV3RD?

Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: REV3RD