Researchers reproduce the surface of a human tongue thanks to 3D printing

Researchers at the University of Leeds, in collaboration with Edinburgh University, have 3D printed soft synthetic surfaces with the same texture as a human tongue. Made of silicone, they could mimic the topology, elasticity and wettability of this complex organ. An innovation that could open up new possibilities in terms of testing the properties of food, pharmaceuticals and also help to better understand certain reactions (such as dry mouth) without having to do it on a human being.

The tongue is a complex organ composed of several muscles, highly vascularised and capable of transmitting taste thanks to its many taste buds. These cover the whole of the tongue, and allow us to perceive five tastes: sweet, salty, sour, bitter, umami, the rest being perceived by the sense of smell. These papillae give the tongue a very special surface, which is not easy to reproduce. However, researchers at the University of Leeds have taken up the challenge and opted for 3D printing.

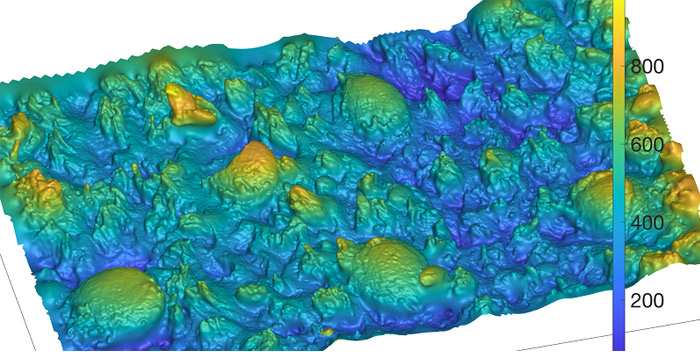

The structure of the human tongue is complex | Credits: Anwesha Sarkar

Dr. Efren Andablo-Reyes, Director of Research, explains: “Recreating the surface of an average human tongue comes with unique architectural challenges. Hundreds of small bud-like structures called papillae give the tongue its characteristic rough texture which, combined with the soft nature of the fabrics, creates a mechanically complicated landscape. We have sought to reproduce the important mechanical characteristics of the human tongue (i.e. the pleasant perception of the oral sensation and adequate lubrication for swallowing) in a surface that is easy to use in the laboratory to reproduce the conditions of oral treatment.”

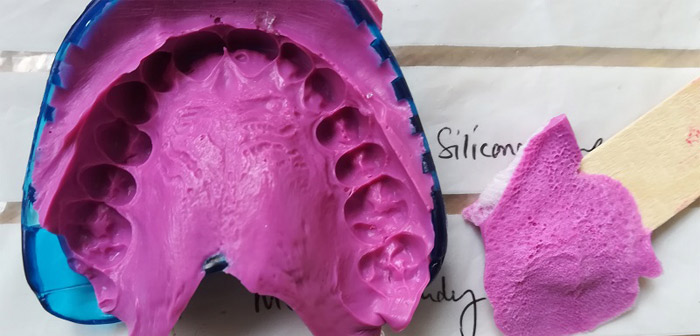

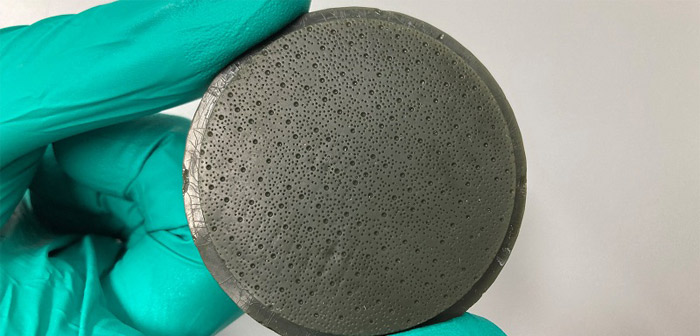

The team explains that they took silicone impressions of the tongue surfaces of fifteen adults. These were then optically scanned to map the size of the papillae, their density and the average roughness of the tongues. Using computer simulation and mathematical modelling, the researchers designed a 3D printed mould that randomly reproduced the shape and dimensions of the different papillae with the correct density. The surface could thus be moulded with elastomers, whose flexibility and wettability were optimised. It seems that the team used a DLP 3D printer to 3D print the surface of the mould.

15 impressions were made | Credits: Anwesha Sarkar

Several tests were then carried out to check whether the surface reproduced the characteristics of a tongue. The researchers used different fluids of varying complexity to see how they acted in contact with the tongue. The results appeared to be identical to those obtained on the silicone prints.

Such a research project could have a big impact on the food and health sector. Anwesha Sarkar, Principal Investigator, explains: “This project is crucial to understand quantitatively how fluids interact in the oral cavity. The biomimetic surface of the tongue we have created could serve as a unique mechanical tool to help detect counterfeits in food and beverages, based on texture attributes, which is a global concern and can help ensure food safety.” It could also be applied to pharmaceuticals and help develop new therapeutic technologies. Find the full study HERE.

The 3D printed moulds include small holes to reproduce the shape and size of taste buds | Credits: University of Leeds