Researchers Find New Use for Biodiesel Waste in Eco-Friendly 3D Printing

Industrialization, population, and economic growth are driving rising energy demands and an increased need for renewable fuel sources such as biodiesel, biogas, and bioethanol. These fuels aim to mitigate the greenhouse gas effect and are derived from renewable resources. For instance, biodiesel production is expected to grow by 4.5% annually. However, this rapid expansion also results in the generation of waste products, including glycerol and a non-glycerol mixture known as Matter Organic Non-Glycerol (MONG), which are currently disposed of in landfills.

To minimize the carbon footprint of biodiesel production, alternatives to landfilling these materials are being explored. One promising solution is converting MONG into value-added products. The demand for environmentally friendly solutions and bio-based materials in 3D printing is ever-growing. The residual fatty acids from biodiesel waste contained in MONG have the potential to be used in the production of filaments. However, there is still limited data on their consistency, and the properties of Matter Organic Non-Glycerol can vary depending on the production process and the substrate used, such as soy or rapeseed.

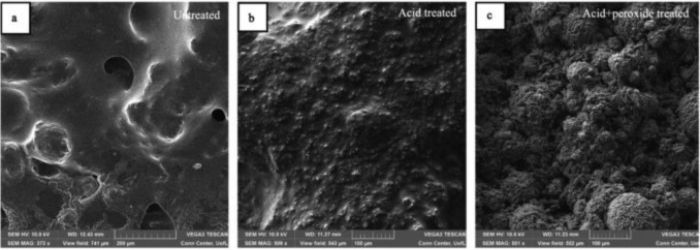

The surface structure and lump formation of MONG. (A) untreated, (B) acid-treated, and (C) acid- and peroxide-treated. (Photo Credits: University of Louisville)

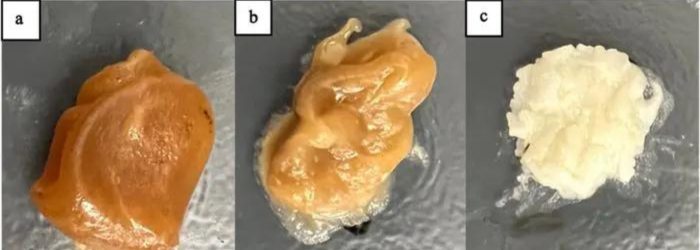

For this reason, researchers at the University of Louisville are investigating the potential uses and properties of MONG, discovering its potential as a copolymer. They conducted various pre-treatments to enhance its stability as a copolymer and NFC filament. In these treatments, the research team combined the resulting MONG copolymer paste with thermoplastics to produce a 3D printing material. In their initial analysis, they examined MONG from soy biodiesel processing plants in three different states: untreated, acid-treated, and acid- and peroxide-treated. The untreated MONG is solid, making it unsuitable for 3D printing. However, the treated counterpart is stabilized and forms a manageable paste, suitable for use in 3D printing applications.

The surface composition analysis reveals that MONG paste treated with acid and peroxide forms stronger lumps, enhancing compatibility between MONG and polymer for filament extrusion. Additionally, treated MONG demonstrates improved thermal stability, exhibiting less weight loss at higher temperatures. Consequently, this treated paste is well-suited as a potential substitute for synthetic polymers in natural fiber composites. It could be effectively used for filament extrusion and polymer blending in the future.

MONG samples. (A) untreated, (B) acid treated, and (C) acid + peroxide treated. (Photo Credits: University of Louisville)

The conversion of MONG offers considerable potential and can be applied not only to soy biodiesel but also to other substances like biogas, ethanol, and even used cooking oil. As a copolymer, MONG can reduce the proportion of synthetic polymers in natural fiber-reinforced plastics, making the process more sustainable and enabling the reuse of waste and residual materials from biofuel production. With continued research, MONG could play a key role in the future of sustainable production technology. To learn more about this project, click here.

What do you think of the use of MONG in 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: University of Louisville