Researchers Develop Revolutionary 3D Printed Coral-Inspired Bone Graft

A team of researchers at Swansea University have 3D printed a coral-inspired bone graft. What’s remarkable? Their study found that the new material not only dissolves naturally in the body after the repair is complete but that it also promotes faster healing.

Bone defects caused by fractures, tumors and non-healing injuries are among the leading causes of disability worldwide. While it is true that bone tissue can repair itself through regeneration, factors like aging, disease or the severity of the defect can slow regeneration down. In the case of large defects, a scaffold or bone graft is necessary to supplement tissue regeneration.

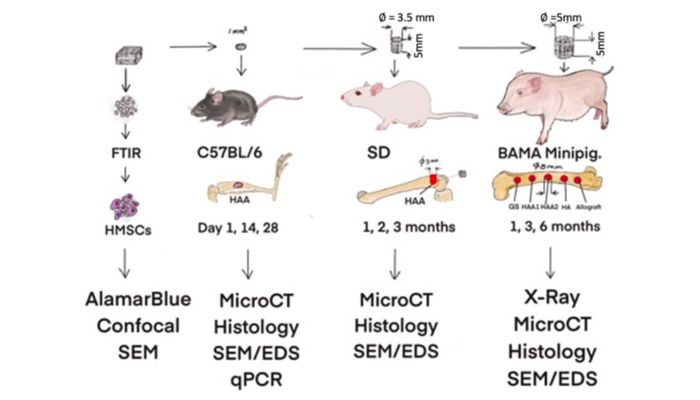

Design of in vitro and in vivo tests (Credits: Swansea University)

Traditionally, doctors use a patient’s own bone (an autograft) or donor’s bone (an allograft) to fill these gaps. But limited supply, risk of infection and ethical concerns make these options less attractive. Synthetic bone grafts exist, but they currently cannot match the performance of natural bone. They either take a long time to dissolve, don’t integrate well or can cause side effects like inflammation. By contrast, the material developed by the Swansea team closely mimics natural bone in both structure and biological behavior, overcoming those challenges.

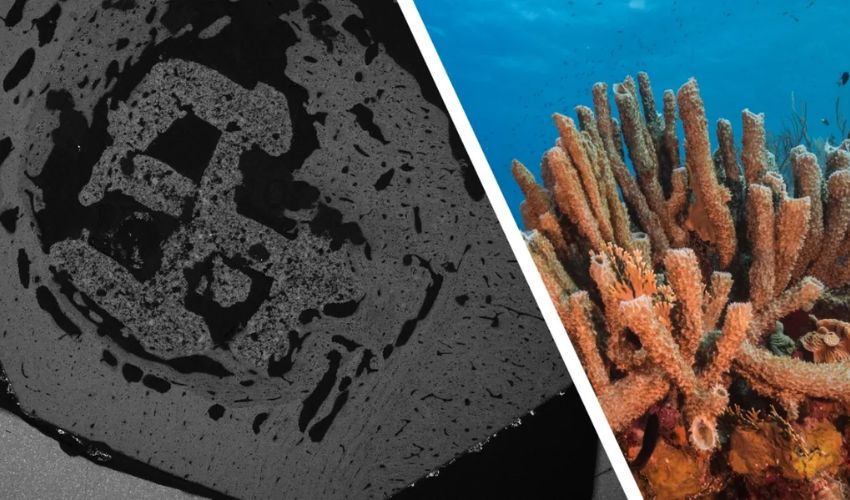

Why Coral?

Researchers began exploring corals as potential bone graft substitutes in the 1970s, and they found that certain coral is similar to that of cancellous bone. It shares mechanical properties with bones, and is also biocompatible, osteoconductive and biodegradable. Since then, natural coral porous calcium carbonate has been deemed “clinically useful bone replacement graft material,” by the Journal of International Oral Health. With this history in mind, the Swansea team developed a new material mimicking the porous structure and chemical composition of a coral-converted bone graft substitute. They 3D printed this material using a 3D-Bioplotter from Envisiontec or molded the material and left it to dry at room temperature.

The research team conducted preclinical in vivo trials, in this case, using rats and minipigs. Notably, the trials showed that the material fully repaired bone defects within three to six months. What’s more, the material triggered the formation of a new layer of strong, healthy cortical bone in four weeks.

Revolutionary Outcomes

The structure has numerous incredible benefits. For one, it permitted rapid healing, with new bone growth occurring in just two to four weeks. Additionally, the material naturally degrades within six to twelve months after bone regeneration, leaving only healthy bone behind. What’s more, the material will be easier to access than its traditional alternatives, natural coral or donor bone. It is easy to produce in large quantities.

Dr. Zhidao Xia of Swansea University Medical School led the research, along with faculty from the Science and Engineering departments and other external partners. Late this November, the team published the patented research.

“Our invention bridges the gap between synthetic substitutes and donor bone,” Dr. Xia said. “We’ve shown that it’s possible to create a material that is safe, effective, and scalable to meet global demand. This could end the reliance on donor bone and tackle the ethical and supply issues in bone grafting.”

Implants in minipig (Credits: Swansea University)

Now, the Swansea University team is seeking to make their technology available globally by partnering with companies and healthcare organizations. The 3D printed bone graft alternative could reduce healthcare costs and improve patient quality of life. And the impact doesn’t stop there: the research invites new opportunities for the biomedical industry. To learn more, read Swansea University’s press release here.

What do you think of the 3D printed coral-inspired bone grafts? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: (Left) An image of a 3D-printed material implanted in vivo for 4 weeks. The photo was taken using a scanning electron microscope. Credit: Dr Dr Zhidao Xia. (Right) A photo of coral. Credit: Jesus Cobaleda.