Researchers Develop New Method to 3D Print Magnets

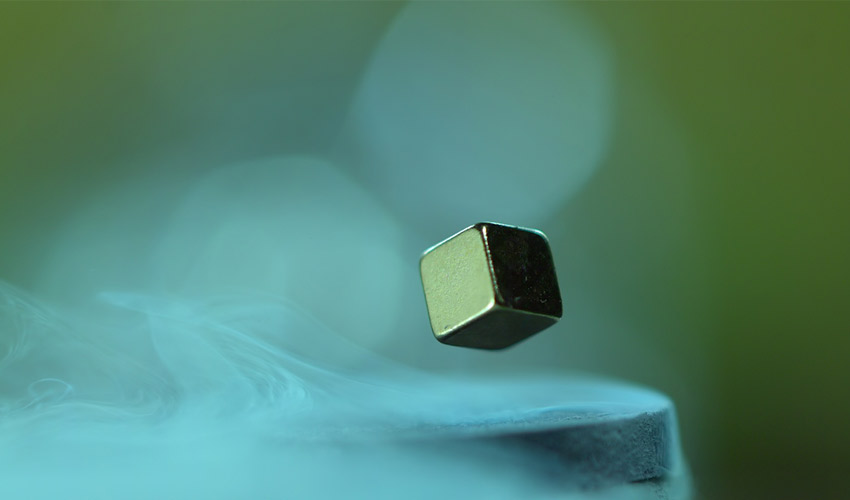

Teams from the Jean Lamour Institute (IJL), the Materials Science research laboratory of the University of Lorraine, have developed a method for producing magnets with a desktop FDM 3D printer. The researchers claim to have succeeded in integrating magnetic properties into various 3D printed parts, all without post-magnetization: presumably by using ferromagnetic materials. This is a first in the 3D printing sector and could open up a field of possibilities when it comes to creating magneto-active objects through which it would be possible to control more or less complex parts with a magnetic field.

Research into 3D printing materials is continuing and accelerating, whether in the polymers, metals or composites markets. It is these developments that now allow users to design parts for industrial applications that meet more or less stringent requirements. For example, the aluminum oxide designed by Austrian researchers, which is highly resistant to corrosion and temperature and extremely rigid liquid crystal filaments. The goal is simple: to be able to 3D print parts with the same characteristics and properties as machined or molded components. In the case of our French researchers from the University of Lorraine, they have focused on magnetism. Namely, how to 3D print magnetized elements, without going through a post-magnetization phase.

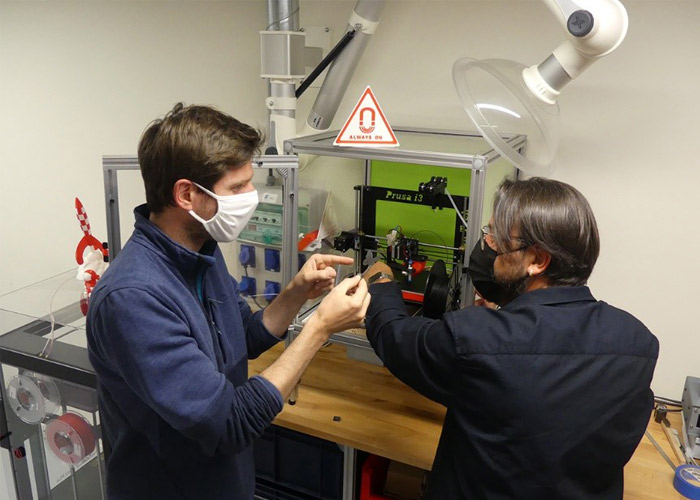

The researchers used a Prusa i3 3D printer to create their 3D magnet (photo credits: University of Lorraine)

Led by Samuel Kenzari, a CNRS research engineer, and Thomas Hauet, a lecturer at the University of Lorraine, the team explains that they have designed a 3D printer that can extrude a composite magnetic filament. The machine is thus similar to a classic desktop FDM solution that they have modified to make these magnets. Few details have been released about the changes made, but an initial version of the printer is expected to be commercially available starting in the fall of 2021. What is interesting is the material developed: the researchers started from ferromagnetic materials that they then transformed to make printable. They thus obtain a magnetic filament though on the topic of what it is exactly the researchers remain discreet. However, the press release adds, “The parts produced by this printer have one or more permanent magnetic orientation(s) without requiring the application of a magnetic field a posteriori to magnetize them.”

The IJL’s objective is to commercialize this solution (machine + filament) by the end of the year, giving everyone the possibility to design their own magnets directly at home. The research work could also help accelerate developments in 4D printing. In 4D printing fourth dimension, time, is included along with the traditional three dimensions to which we are accustomed. The parts created by 4D printing would be able to undergo a transformation under the effect of an external factor such as temperature, vibrations, etc. We could therefore use this filament to design parts that a user would control via a magnetic field, thus modifying its shape for example.

What do you think of these 3D printed magnets? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!