Renault 3D Prints Bumpers for TWINGO E-Tech Prototype

Electric cars have been offered as sustainable vehicles for several years now, and Renault is one of the automakers that has joined in on the movement. Through a strategic plan they call “Renaulution,” the company wants “to restore profitability while inventing a new future,” focusing on environmental performance. Last year, Renault unveiled its new TWINGO E-Tech prototype at the Mondial de l’Auto 2024 in Paris and then at the Brussels Motor Show this January. The electric TWINGO E-Tech is reminiscent of the historic Twingo model, but modernized with smart upgrades and 3D-printed black bumpers. The car will be commercially available in 2026 for less than €20,000.

Renault is no stranger to sustainability, as its first electric prototype, the Renault NEXT, was presented in 1995. Since then, the brand has increasingly specialized in technological innovation, and through its partnership with Ampere, Renault has been developing smarter electric vehicles with cutting-edge software since 2022. Numerous models in the electric range are currently offered by the company, including the Renault 5 E-Tech, Renault 4 E-Tech, Megane E-Tech and Scenic E-Tech.

The prototype of the Twingo E-Tech pwas resented in Brussels this January. (Photo credit: Renault Group via Linkedin)

Designed in just two years, the TWINGO E-Tech prototype was created specifically to meet the needs of city living. It is compact but has ample space in the interior, thanks to its sliding and folding seats. It also includes two electric displays, LED headlights with a modern design, a front headrest equipped with a magnetic mount and an air intake inserted into the front end of the car to improve its aerodynamics.

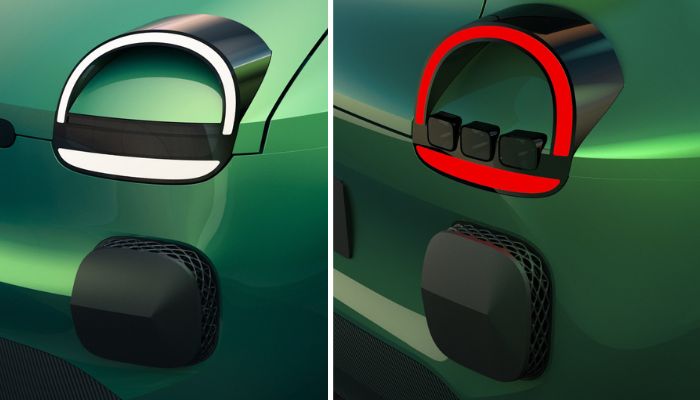

TWINGO E-Tech 3D Printed Prototype Bumpers

The first version of the TWINGO E-Tech, unveiled in Paris last October, did not yet include the 3D printed bumpers. These protective devices were additively manufactured to recreate honeycomb structures. This type of design falls within the scope of biomimicry, which involves designs imitating biological structures. Why did Renault adopt this design? The hexagonal honeycomb structure recalls another type of design often created with 3D printing technologies, namely lattices. Lattices are used in construction to make structures lighter because they relieve excess material while remaining strong because they have great energy absorption.

In these two photos, we can see both the front (left) and rear (right) bumpers, equipped with the characteristic honeycomb latticework, and the LED headlights with a modern design.

So, Renault created bumpers that were not only lightweight but also had optimal characteristics to respond to possible external impacts. The company did not specify the type of 3D printing technology used. But will it expand their use of 3D printing in the future? It is not the only brand that has used 3D printing technologies to enrich its models. Other automakers have also adopted this technology to improve the performance of their vehicles, too, evidence of additive manufacturing’s recognized value in the automotive sector.

What do you think of the TWINGO E- Tech? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! For more on automotive 3D printing, click here. Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Renault