Redwire Has 3D Bioprinted the First Human Knee Meniscus in Space

When it comes to innovation in outer space, additive manufacturing is on the front lines as we continue to push boundaries while exploring the final frontier. Indeed, the flexibility and ability to produce locally are two of the main reasons why the technologies have been adopted for space exploration with applications ranging from 3D printed habitats to food. Now we have yet another project to include. Redwire has announced that it has successfully 3D bioprinted the first human knee meniscus in orbit. This was done in the 3D BioFabrication Facility (BFF) on the International Space Station (ISS). The part was made as part of the larger project BFF-Meniscus-2 in conjunction with The print was conducted as part of the BFF-Meniscus-2 Investigation with the Uniformed Services University of the Health Sciences Center for Biotechnology (4D Bio3). 4D Bio3 is a biomedical research center exploring adapting biotechnologies specifically for warfighter benefit, including of course bioprinting.

Redwire is no stranger to research on the ISS. They have developed 20 research facilities for the ISS with 10 currently operating on the station. This includes work into seeing whether regolith can be used to 3D print structures on the Moon and Mars. Additionally, it is actually the second time that they have worked on making a 3D bioprinted knee meniscus, in 2019 the BFF 3D printed a meniscus-shaped scaffold using bioink derived from human tissue proteins. But this experiment will be the first time that a full human knee meniscus has been bioprinted in space using living cells. The company hopes that it will open the door to improved treatments for meniscal injuries which aren’t just one of the most widespread knee injuries worldwide but also one of the most common injuries for U.S. service members.

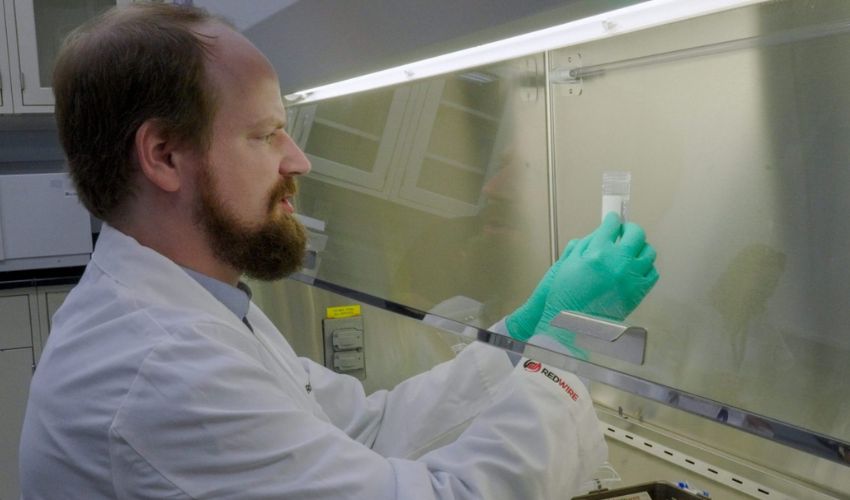

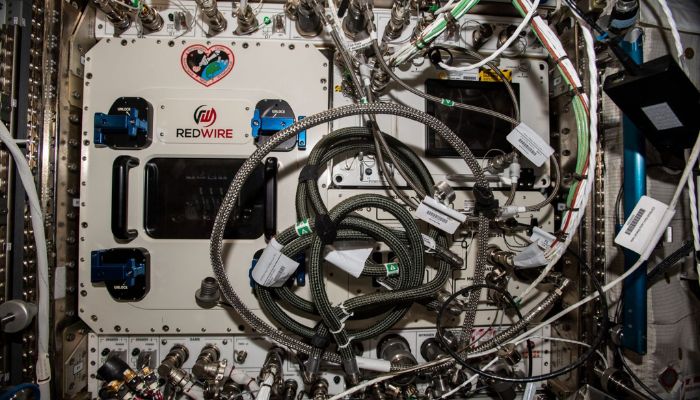

The 3D bioprinted meniscus was done on Redwire’s special bioprinter which was recently installed on the ISS

Making the 3D Bioprinted Meniscus

As mentioned, meniscal injuries, and most specifically torn menisci, are some of the most common knee injuries. Considering that the two menisci in the knee work as shock absorber in the knee, this can be a real issue. Especially as symptoms often involve the catching or locking of the knee joint as well as the inability to fully extend or bend it. This is why Redwire believes this incredible milestone could have considerable implications for human health even on Earth.

The BFF created the 3D bioprinted meniscus by using living human cells in bioinks which were then printed on a bioprinter that was installed on the ISS. Once completed it was cultured for 14 days on the ISS in Redwire’s Advanced Space Experiment Processor (ADSEP). The meniscus was then returned to Earth onboard the SpaceX Crew-6 Mission for analysis with investigation conducted by NASA astronauts Frank Rubio, Warren “Woody” Hoburg, and Stephen Bowen and UAE astronaut Sultan Al Neyadi. Furthermore, already the company is planning future projects. On an upcoming SpaceX CRS-29 resupply mission in November, the company will launch microgravity research payloads focused on pharmaceutical drug development and regenerative medicine including an experiment to bioprint cardiac tissue according to a press release.

Discussing the completion of the 3D bioprinted knee meniscus, Redwire Executive Vice President John Vellinger concludes, “This is a groundbreaking milestone with significant implications for human health. Demonstrating the ability to successfully print complex tissue such as this meniscus is a major leap forward toward the development of a repeatable microgravity manufacturing process for reliable bioprinting at scale.” You can learn more on Redwire’s website HERE or in the video below where Dr. Aaron R. explains more about why the company has undertaken this project.

What do you think of this 3D printed knee meniscus from Redwire? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Redwire