Reconstructing dinosaur’s skeleton with large-format 3D printer

In the Netherlands, the Naturalis Biodiversity Centre has used 3D scanning and additive manufacturing to bring to life an animal that has been missing for millions of years: the triceratops. The project teams were able to reconstruct its entire skeleton by digitizing its bones as well as those of other dinosaurs in the same family. They then used 3D Builder printers to create the necessary bones. The final result is very realistic and will allow the many visitors to better visualize the dimensions of a triceratops.

3D technologies have often made it possible to reconstruct our past, whether it be works of art, historic sites ravaged by war or extinct animal species. You may also remember this giant triceratops displayed in Austerlitz station, Paris designed on a large format Massivit 3D printer. 3D printing can therefore help to better understand periods, cultures, architectures or simply to visualize something abstract.

Credits: Naturalis

Reconstructing dinosaur skeleton using a large-format 3D printer

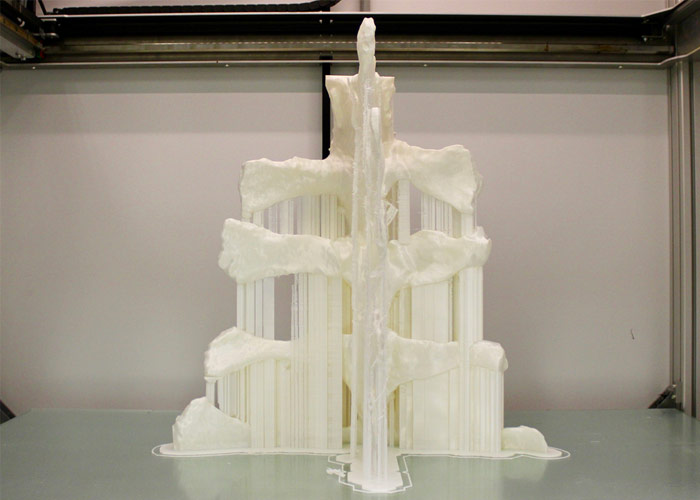

The triceratops in question is called Dirk and its skeleton was dug near Newcastle and is about 67 million years old. Paleontologists have identified a number of missing bones, including ribs, one of the horns and a large part of the skull. They decided to rebuild them in order to expose the entire skeleton at Naturalis. Using FDM 3D printing for 2 years, they turned to the Builder Extreme 1500 PRO printer to create larger parts – some Dirk bones are between 50 and 130 cm long.

Any printing starts with a 3D file, usually obtained by scanning or 3D modeling. In the case of this project, the scientists explain: “If we have, for example, a left bone and the right-side counterpart is missing, we can easily make a scan and a mirrored 3D print“. But this was not always the case, so they scanned the bones of another skeleton located in another museum. The team points out that not all Dirk’s bones are exposed, it wanted to preserve the most fragile ones such as certain veins.

One of the 3D printed bones of Dirk’s spine | Photo Credits: Naturalis

For 2 months, the 3D printer printed more than 100 bones with very high precision. Once printed, each piece was hand painted, slightly lighter in colour than the real bones, giving visitors the opportunity to distinguish between real and artificial pieces. The Builder Extreme 1500 PRO printer is also on display to explain to visitors how paleontologists work. Peter H. Schalk, Director of Public Sectors and Markets at Naturalis, concludes: “Modern day palaeontologists use 3D imaging and printing techniques as an instrument to reconstruct fossil remains that are discovered in scientific excavations. An industrial Builder Extreme 3D printer is deployed in the LiveScience gallery of the new Naturalis museum as an ongoing demonstration to the public how missing parts are printed and fitted in dinosaur skeletons.”

Visitors can admire the skeleton of the triceratops since last month in the LiveScience gallery. It will surely allow many a curious person to discover 3D printing! You can find more information HERE.

3D printing of tibial bones | Photo Credits: Naturalis

What do you think of this reconstruction of Dirk using 3D printing? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!