The Top PEEK and ULTEM FDM 3D Printers on the Market

Additive manufacturing users are increasingly looking for technical materials that meet their requirements and constraints. As a result, we have seen the materials market grow exponentially in recent years, with the aim of offering higher-performance solutions. This is true, for example, of the high-performance thermoplastics segment, better known to many as PEEK, PEKK or PEI. Mainly marketed in filament form, they have quite impressive chemical characteristics and mechanical properties, sometimes approaching those of certain metals. But they also involve more complex printing parameters, namely an extrusion temperature of over 350°C, a heated chamber and a printing plate capable of rising to over 100°C. These technical constraints explain the relatively small number of compatible 3D printers on the market. To help you in your search, 3Dnatives has compiled an alphabetical list of FDM 3D printers capable of printing PEEK and ULTEM materials.

Apium P400

Launched in 2022, the Apium P400 3D printer has been developed by the eponymous German manufacturer. It offers a print volume of 400 x 300 x 300 mm, a build plate capable of reaching 200°C and a nozzle capable of rising to 540°C. Equipped with an IDEX system, it can print two identical parts simultaneously or in mirror mode, increasing user productivity. But what’s particularly interesting about this 3D printer, compatible with PEEK and ULTEM, is that it features a zone heating system: it’s not the whole chamber that’s heated, but an infrared heating device integrated into the printer head. This makes it possible to better regulate energy consumption and achieve better adhesion between layers.

BigRep’s ALTRA 280 3D Printer

BigRep’s ALTRA 280 is an industrial FDM printer for high-performance materials with a large print chamber and up to four extruders. The machine features a 500 mm x 700 mm x 800 mm print chamber (print volume of 280 liters ), which enables the production of complex prototypes and end-use parts. The printing chamber and printing table reach temperatures of up to 180°C, enabling the use of high-performance materials such as ULTEM 9085 and PEEK. During printing, the chamber also acts as a hardening system, improving the mechanical properties, functionality and dimensional stability of parts. The 4 DSXs (Direct Synchronized Extruders) are capable of printing at 450°C up to 20 kg in one cycle to provide uninterrupted production with two respective backup extruders. In addition, each DSX features integrated cooling channels and multiple sensors for monitoring and control. The machine is suitable for applications in high-performance industries, such as aerospace, as well as for the production of robust, geometrically complex tooling and functional prototypes.

Creabot PEEK-300

The Chinese manufacturer Creatbot has developed a 3D printer capable of making parts out of PEEK. It is particularly unique because it integrates a “Direct Annealing System”, i.e. an annealing process during printing in order to give the parts the best possible quality, without deformation or cracking. This technology avoids time-consuming post-processing steps. The Creabot PEEK-300 is a dual extrusion machine, capable of heating up to 500°C. Its printing plate can heat up to 200 °C while its chamber reaches 120 °C. It offers a printing volume of 300 x 300 x 400 mm in single extrusion (240 x 300 x 400 mm in double). Finally, it is a relatively compact machine that integrates a number of features to facilitate the printing process.

EXT 220 MED 3D Printer From 3D Systems

The EXT 220 MED 3D printer from 3D Systems not only can be used with high-performance polymers, including PEEK, PEKK PPSU, but it is also specifically designed to create medical implants. Currently it is the only platform to boast both an integrated clean room and temperature control, making it suitable even for use in hospitals. The printer has a build volume of Ø 220 x 160 cm and features like a fully controllable build chamber heating, laminar airflow for homogeneous temperature distribution, adaptive local temperature management and optimization for clean rooms, along with ASTM F2026 validation and high-performance polymer compatibility, make it perfect for use in medical settings. Indeed, it has already been used for applications like craniomaxillofacial implants, interbody fusion devices, trauma bone plate trial implants and retractor blades. Its max operating temperature is 500°C for the nozzle, 300°C for the build plate and 250°C for the build chamber.

The F3300 From Stratasys

Stratasys takes industrial FDM 3D printing to the next level with the F3300, offering up to twice the speed and throughput of traditional FDM printers, while reducing total cost per part through more efficient use of materials and increased part yield. Thanks to cutting-edge hardware and software solutions, it also improves productivity and print reliability, making it the ideal printer for sectors such as automotive, aerospace, general manufacturing and medicine. The F3300 reduces printing time thanks to user-friendly functions such as autocalibration. The printer is also capable of processing a wide variety of materials, including ASA, nylon 12CF FDM as well as ULTEM™ 9085 and Antero 800NE, a PEKK-based material. It measures 600 x 600 x 800 mm and weighs 1360 kg.

Photo Credits: Stratasys

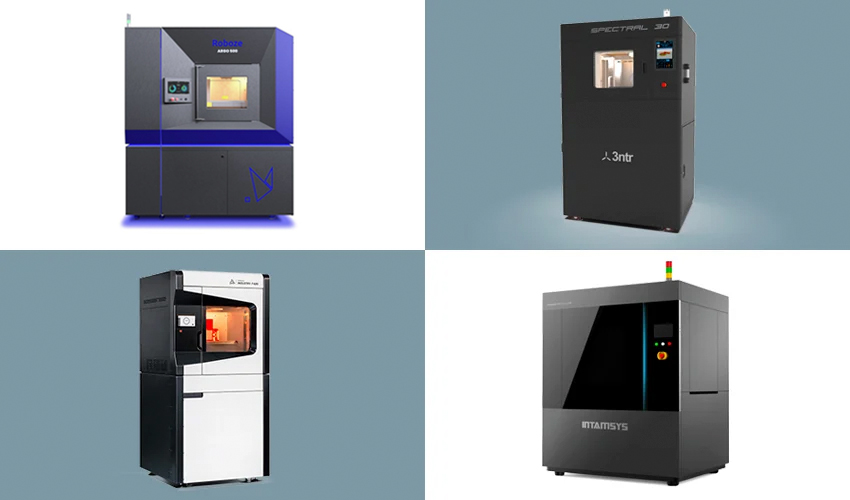

FUNMAT PRO 610HT

The FUNMAT PRO 610HT, from industrial FFF 3D printing solution provider INTAMSYS, is ideal for large-format 3D printing (build volume of 610 x 508 x 508mm) of high-performance materials such as PEEK, PEEK-CF, PEEK-GF, PEKK, PEI9085, PEI1010 and PPSU with a 300°C uniform heated chamber and dual nozzles reaching 500°C (allowing the use of support materials). The build chamber has also been optimized with a liquid-cooling system for enhanced dissipation, helping to avoid warpage and other issues for parts with higher mechanical strength.

The printer boasts superior surface finish for complex geometries thanks to a closed-loop servo control system. Furthermore, it integrates auto-cleaning nozzles as well as filament auto-reloading, jam warnings and absence warnings to ensure seamless continuous printing 24/7. The FUNMAT PRO610HT has a Grade D certification in CE & MD standards, CE (EMC/RED/LVT) certified for industry-grade application standards. Find out more HERE.

Photo Credits: INTAMSYS

The Gearbox HT2 PEEK 3D Printer From 3DXTECH

Michigan-based 3DXTECH was founded in 2014 with the goal of taking 3D printing functionality to the next level. Among the PEEK FFF 3D printers they offer we find the Gearbox HT2, a machine designed to print large-scale, fast and accurately. Among its technical aspects, its maximum printing volume of 457mm x 457mm x 813mm stands out, as well as its high manufacturing temperatures, both of the chamber (up to 225ºC) and the extruder (up to 500ºC). It also has a vacuum printing plate, a removable plastic sheet as a manufacturing surface and a filament storage system with heating and active drying. All this allows the creation of parts with high performance materials (PEEK, PEKK, Ultem, PA12, PA6, PC, etc) and special grade materials (carbon fiber, fiberglass, flame retardant, etc). We leave you a video below to discover more about 3DXTECH’s Gearbox HT2:

The Essentium HSE 280i HT PEEK 3D Printer

Nexa3D, founded in 2016, is a company that specializes in developing and manufacturing the fastest 3D printers in the world. With the integration of Essentium, Nexa3D expands its portfolio with the Essentium HSE 280i HT, the first PEEK 3D printer whose dual extruders are independent of both the X and Y axes (IDEX). The Essentium HSE 280i HT is able to solve problems in terms of speed, durability and scalability. It also has an open ecosystem, which is demanded by 96% of manufacturers as it gives them greater control. As for the technical specifications of this printer, it has two print heads, a Hoozle Generation 5 heated nozzle with a diameter of 0.4 to 0.8 that reaches 550ºC. It has a size of 1590 x 1350 x 2490 mm and a weight of 850 kg. Watch the video below to find out more about the 3D printer:

Hylo, a Machine Designed by AON3D

Following on from the AON M2+, the Canadian company’s fifth generation of high-temperature 3D printers, AON3D presents Hylo. This is an industrial machine featuring a 650 x 450 x 450 mm printing plate and a printing chamber that can rise to 250°, all in a controlled and precise manner. Hylo is driven by software that relies on automatic learning to maximize performance and productivity. It incorporates over 25 sensors to monitor the entire printing process, analyze part quality and detect any defects. Printing speeds can reach up to 500 mm/s. In terms of materials, Hylo is compatible with standard polymers, composites and, of course, high-performance materials.

Photo Credits: AON3D

INDUSTRY F421 From 3DGence

The INDUSTRY F421 from 3DGence is one of the company’s industrial 3D printers designed to print high performance polymers such as ULTEM, PEEK and PEKK. According to the manufacturer, this machine guarantees the best quality, dimensional accuracy and reproducible results and impresses with its printing speed of up to 400 mm/s and 1 meter per second. This makes the INDUSTRY F421 a great tool for rapid prototyping. The large print volume of 380 x 380 x 420 mm allows for the printing of large models in one run. The 3D printer also allows printing of high-performance materials that are additionally reinforced to make the resulting final parts even more durable. Each 3DGence INDUSTRY F421 can be equipped with hardware that enables the safe printing of reinforced materials. The INDUSTRY F421’s filtration system also provides extremely good filtration performance, which is not often found in printers powered by FFF technology. The advanced three-stage filtration unit retains macro particles, nanoparticles (VOC, UFP), solvent vapors or harmful gases, enabling user safety and continuity of the technological process.

MAGIC-HT-MAX

Introduced earlier this year, the MAGIC-HT-MAX follows the line of 3D printers offered by the Asian manufacturer IEMAI 3D and is capable of manufacturing high performance parts, the machine uses FDM technology to manufacture with more than 16 different materials (PEEK, PEKK, ULTEM,…). It has a printing volume of 500 x 500 x 700mm and a heated tray that reaches 180°C. In addition, it integrates a liquid cooling system, an end of filament sensor and the ability to recover and resume printing in case of power failure. Despite being an industrial machine, the manufacturer specializes in providing affordable solutions for players in the additive manufacturing industry.

miniFactory Ignite PEEK 3D Printer

miniFactory Ignite PEEK 3D Printer

With the IGNITE, miniFactory offers an industrial 3D printing solution at a great price for the performance. The company’s clear aim is to offer high-performance technology at the best price and in the best quality. The IGNITE offers a generous build area (600 x 400 x 400 mm) and a large selection of materials. With the IGNITE you can, among other things: ULTEM AM9085F™, PACF, ABS, ASA, PEKK-A, PVDF, PEEK and PEKK. The printer has a heated chamber and an integrated station for drying the filaments. The double extruder also makes it easy to print support structures. The printer is suitable for prototypes, large-format models and end-use parts. To check the quality during the printing process, the printer can be controlled remotely and there is a layer-by-layer check.

A150 Series

Orion AM is a company dedicated to industrial additive manufacturing for advanced applications using aerospace-grade polymers. As such, it should come as no surprise that their A150 Series of 3D printers is compatible with high-temperature, high-performance polymers including PEEK and PEKK. This advanced industrial additive manufacturing system allows for the 3D using Thermal Radiation Heating, a process using thermal radiation in all directions to efficiently heat the printed object up to 300°C, allowing the resulting parts to have superior strength properties. The printing bed has a max temperature of 300°C and the extruder has a max temperature of 500°C. Additionally, thanks to TRH the chamber temperature can reach 315°C while the layer heater temperature goes up to 370°C. The solutions are compatible with PEEK, PAEK, PEKK, PEI, ULTEM1010, ULTEM9085, ABS, PC, PA6, PA12 and PPSF/PPSU.

Photo Credits: Orion AM

Roboze ONE +400 Xtreme

Italian 3D printing manufacturer Roboze specializes in the production of large parts as well as custom batches with its solutions, including the ARGO 500. Introduced in 2017, the maximum extruder temperature for this printer is 550 degrees, with 180 degrees for the build chamber. Manufactured for professional use, the 3D printer has a print bed size of 500 x 500 x 500 mm, in addition to a total weight of 1700 kg. A specific feature of the ARGO 500 is definitely the fully automatically regulated process variables: from the leveling of the build plate to the calibration of the extruder or even the automatic change of the filament: everything is automated and does not require human assistance. Moreover, this 3D printer is equipped with remote maintenance modules that reduce downtime and thus increase productivity.

Spectral 30

The Italian manufacturer of high-performance 3D printers, 3ntr has developed a machine compatible with PEEK, ULTEM and PPS. It is equipped with a powerful electronic system to control the temperature in an optimal way and thus allow the creation of complex parts with high mechanical properties. It has a volume of 300 x 300 x 300 mm, four extruders with a temperature range up to 500°C, a chamber up to 250°C, and comes with a heated compartment for storing high-performance thermoplastics. The build plate can be heated up to 300°C.

Zortrax Endureal

Last year, Polish manufacturer Zortrax presented its new machine called Zortrax Endureal. With a print volume of 400 x 300 x 300 mm and a maximum precision of 100 µm on the Z-axis, it is equipped with a dual extruder and an aluminium build plate to improve the adhesion of high-performance thermoplastics. Among its features is an advanced thermal management system that makes it easier to control the temperature of the chamber as well as the extrusion temperature. There are also 17 sensors so that the user can monitor the print job in real time and be alerted in the event of a machine failure. Zortrax offers its own range of materials including Z-PEEK, which is wear and abrasion resistant; Z-PEI 9085 for aerospace, Z-ESD, and Z-ULTRAT Plus. According to the manufacturer, the Zortrax Endureal is an ideal industrial machine for designing aerospace and medical applications.

Did we miss any PEEK or ULTEM 3D printers in our ranking? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Hydra 3D Printer from Indian Manufacturer AMS India (http://ams-india.co.in/additive-mfg/) can also handle PEEK and PEKK. The extrusion head goes up to 370 deg C and also the print bed can upto 120 deg C. AMS has done many projects in PEEK 3D printing for Indian space systems.

Zortrax Endureal is also compatible with PEEK

How about an industrial composite high-temperature 3D printer?:) https://anisoprint.com/solutions/industrial/

Well, come on! What are the prices? That’s the only thing worth knowing about the machines.

CreatBot PEEK-300 is missing

A price tag for eahc machine would be nice to have

Samuel is so correct! There’s no point in detailing print head specs without mentioning price. As long as you are sure they actual work with PEAK, what’s needed is print volume, price, service contract, turn around times for repairs.

I cannot fathom the point of telling us about printers they might be $100,000 above our budgets. Asking for quotes is astonishing. They have prices just show them!

Have you considered the Orion Additive Manufacturing PEEK 3D printer? It uses Thermal Radiation Heating to heat the material up to 300C in order to fuse the parts together to make them as strong as injection molded parts.

Essentium also has a new high temp printer with dual independent extruders.

You left out Stratasys??? LOL

No mention of Stratasys printers? The Fortus platform has printed thousands of flight parts, in the sky right now, with Ultem 9085. The Antero (PEKK) materials also have become popular for space applications, especially the ESD variant.

Seems disingenous to not mention them.

Indeed, you are correct, though Stratasys was included in the list, the chosen 3D printer was deleted accidentally before publication. It has been rectified.