The Top Bicycles Made With 3D Printing

As you know, more and more additive manufacturing is playing an important role in the world of sports, where it allows for the design of custom-made equipment. Cycling is undoubtedly one of the sports where 3D technologies are most widely used. The goal is to create a bike that is lighter, faster, and more comfortable, all while reducing manufacturing time and costs. The technologies and materials used vary, the most commonly used being metal or composite 3D printing, as these are stronger materials. In addition, with 3D scanning, it is possible to customize accessories such as a bike helmet, saddle or grip. In short, the applications in the industry are really many! Below we have outlined, in no particular order, some of the main projects out there centered on bicycles and accessories made with 3D printing.

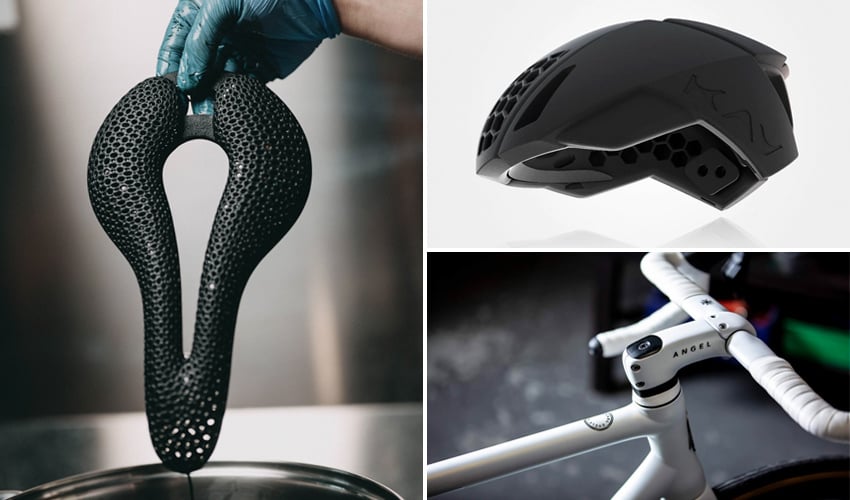

Angel Heaven by Angel Cycle Works

Angel Heaven is a titanium bicycle 3D printed by the Spanish company Angel Cycle Works. Taking the fastest vehicles in the world as their reference, They worked together with the MADIT Metal 3D team for the creation of this unique bike made using SLM 3D printing technology. They use titanium powder, exclusive to their brand, thus managing to customize and obtain unique designs. The high precision of their 3D printers, the hardness of the powder and its triple track support allows them to lighten and eliminate unnecessary material, create new cutting-edge and resistant products, a more direct encounter between the frame and its bearings as well as a very good alignment of all its elements. In addition, its oversized steering system provides absolute precision, a clean, hidden and natural passage of all cables for all types of shifting and braking systems.

Angel Heaven, the titanium bicycle (photo credits: Angel Cycle Works)

Bolide F HR 3D by Pinarello

Bolide F HR 3D is Pinarello’s bicycle made with additive manufacturing. Released in October 2022, the Italian brand claimed at the time that it was the fastest 3D printed bicycle in the world. Indeed, it was designed specifically for use by the cyclist Filippo Ganna for his hour record attempt, the record for the longest distance cycled in one hour on a bicycle from a stationary start. In fact, Gana broke the Hour record in the same month, reaching 56.792 kilometers in that time period, a performance never seen before. In order to make the bike, the bike’s frame and fork were 3D printed using Laser Powder Bed Fusion and an alloy called Scalmalloy, composed of scandium, aluminum and magnesium. The frame is composed of only five individually produced pieces and then glued together. The uniqueness of the Bolide F HR 3D is not limited to the materials, but starts with its design. Pinarello collaborated with the University of Adelaide to create a design inspired by nature and, in particular, the aerodynamics of humpback whale movements. And the result was clearly a success!

Bolide F HR 3D from Pinarello (photo credits: Pinarello)

The 3D Printed Pads From Elastic Interface

Elastic Interface, an Italian company, has developed the first 3D printed chamois pad to offer greater comfort and breathability for cyclists. NX3 chamois pads integrate a 3D printed piece that replaces the usual foam or padding in the support area. Its lattice structure helps to have a more precise control of the density and firmness of the pad depending on its use. In addition, the design allows you to define how the pad deforms under weight and pressure. This in turn results in greater cushioning, more stable behavior and less deformation of the pad. To manufacture the chamois pads, the company has used FDM technology. With this method, they have succeeded in developing a grid shape that also helps air to circulate through the structure. This promotes breathability and prevents moisture accumulation thanks to hydrophobic properties.

Photo Credits: Elastic Interface

The Shadow M1, 3D Printed Electric Bike for the City

The Shadow M1 is a 3D printed electric bike from Belgian startup Shadow Concept. The company was founded with the goal of creating 3D printed, eco-friendly custom bikes. The M1 was created specifically for an urban environment and, as it is an electric bike, also includes a 36v 11.4ah (400wh) battery, allowing users to travel an average of 70 km, though this can be upgraded to 100 km. Moreover, it includes a 3D printed frame that is adapted to each client’s biometric data, allowing the bike to be fully customized to your size, making it more comfortable. In order to make this frame, Shadow used large-format FFF 3D printing and CO2 neutral and biodegradable biopolymers. In addition, it is also equipped with hydraulic brakes and a saddle that was also adapted to the cyclist. Overall, the bike strikes a good balance between comfort and eco-responsibility with all parts, including the battery, which can be easily reconditioned. The bike is available from a starting price of €2,499.00 (~$2,712.62).

Photo Credits: Shadow

Posedla and its 3D Printed Bike Saddle

Based in the Czech Republic, Posedla is on a mission to design the most suitable bicycle saddle for all cyclists, regardless of their skill level. And one way to achieve this goal is through additive manufacturing. Called Joyseat, this saddle is composed of several elements, including a carbon shell but especially a 3D printed padding placed on top of this shell. The part is printed in TPU to guarantee comfort and flexibility. The saddle weighs between 170 and 210 grams depending on the rider’s parameters, with a length of 262 mm. An online configurator is available on the Posedla website so that everyone can design their own saddle, according to their needs, performance and desires. It costs 490 euros to receive such a piece at home.

The saddle is fully customizable (photo credits: Posedla)

Custom Bike Grips From Personomic

Young German startup Personomic, has developed 3D printed, custom-made grips to avoid and prevent hand pain. They are made using Rapid Shape’s DLP printers, producing grips that match the cyclist’s hand. This way pressure is distributed much better, pressure spikes are avoided, and the nerves in the hand are not pinched. Which prevents pain and numbness in the hands when riding the bike for several hours. In addition, the grips can be customized using the company’s Customize tool, which allows you to “customize” color and texture of the grips. Finally, silicone-coated grips are also softer and do not become sticky with weather or sun exposure, according to Personomic.

Specialized and its 3D Printed Bike Saddles

Specialized is a manufacturer of bicycle components that has partnered with Carbon to create 3D printed saddles. Called the S-Works Power Saddle with Mirror Technology, it has been designed to improve rider comfort, protection and performance. Its complex elastomeric carbon-based mesh structure provides better properties than traditional saddle materials such as foam. In addition, one of the problems with more conventional products is uniformity across the entire length of the saddle. With 3D printing, Specialized was able to create multiple zones of varying density and compliance. This allows the rider to have support exactly where they need it.

Photo Credits: Specialized

Openbike, the Bicycle From Arquimaña

You want to get a bike, but why not print it yourself? The architecture firm Arquimaña has developed the Openbike project, a 3D model of a bicycle that users can download, print and assemble. The objective of this product is simple: to preserve the environment. In order to make this product, the firm has made available on its website a list of tools to have for its creation. As its name indicates, the project is open-source. Anyone can download this 3D model. Then, for some components like the saddle or the handles, it is possible to print them in 3D. However, for the frame of the bike, it will be necessary to use the CNC machining process. Regarding the materials needed, PLA seems to be essential to manufacture these elements. Note that there are four versions of the Openbike, from Rev1 to Rev4, and that each model has different characteristics.

The Smart Bike Helmet PYLO

With the development of the PYLO, the German company nFrontier wants to make cycling safer in order to truly become a more sustainable means of transport. This was made possible by the use of Autodesk 3DSMax software and the F370 and J55 3D printers from the manufacturer Stratasys. The helmet is characterized by its innovative functions. It has an integrated, self-opening airbag. This protects the driver’s jaw, teeth and eyes in the event of an accident. In addition, the attached LED lights on the head and rear, as well as a blinder made of LED can be switched on by double tapping. However, what makes the PYLO stand out is its LIDAR (Light Detection and Ranging) technology – a safety system that warns the cyclist when vehicles are approaching at a very high speed. In addition, it informs the rider of potential blind spot hazards, providing optimal conditions for accident prevention. The 3D-printed inner lining and the lightweight material from which the helmet is made do not weigh down the head and make the bike a pleasant and safe means of transport – whether for athletes or recreational cyclists.

Photo Credits: Pylo

Mythos and Metal Additive Manufacturing

The British brand Mythos presented its first printed bicycle stem in 2021. Recall that this is the spare part that connects the handlebars to the pivot of the fork of a bike. Named Elix, this component was designed on a metal 3D printer and is said to be 15% stiffer in torsion. One year later, Mythos completes its range with a new 3D printed stem: IXO was designed on an EBM machine with a titanium certified for aerospace and weighs only 147 grams. it would be 16% stiffer in torsion and 11% stiffer in flexion.

Photo Credits: Mythos

3D Printed Bike Helmets From KAV

It goes without saying that if you’re riding a bike, you’ll probably need a helmet. But many of the choices out there may be considered subpar as they are not the safest choices nor comfortable. However, KAV Sports has a solution to this. Building upon their work in creating 3D printed hockey helmets, the company has also developed a 3D printed helmet that is not only custom-fit, as well as streamlined and light compared to many other helmets, but safer. To achieve this, KAV used 3D printing to create a honeycomb structure within the helmet, adding extra reinforcement in key areas, resulting in a helmet which apparently exceeds helmet certification standards by 25-50%. You can already buy a helmet from KAV including the first version, the Portola, and the newest update, the Portola: Kaze. Though even the cheapest version will set you back about $245, users have already sung the helmets’ praises for safety, fit and performance.

The Portola helmet from KAV (photo credits: KAV)

A Montain Bike With Full Carbon Fiber Suspension.

“Rodeo” is the first mountain manufactured using 3D printing by Revel Bikes. Based in Carbondale, in the U.S. state of Illinois, Revel seeks to demonstrate the potential of additive manufacturing in the creation of carbon fiber bicycles. Jordan Haffener, chief engineer at Revel Bikes, designed and worked on the conception of the Rodeo downhill bike. To do so, they collaborated with 3D printing experts Arevo Inc. to produce the carbon fiber-reinforced bike frame. Moreover, this is not just a show bike, but a fully functional concept. With this innovative project, Revel aims to push the boundaries of additive manufacturing innovation in mountain biking.

Photo Credits: Revel Bikes

INDEXLAB, XGINEERING, & GIMAC’s “New01Bike”

This new project, known as “New01bike”, aims to create a fully functional bike using only recycled materials to promote sustainability and circular economy practices in the manufacturing industry. According to its creators, it is the first ever 3D printed bicycle frame, made from recycled polycarbonate material, and represents the latest evolutionary link in the history of the bicycle. In fact, it’s featured as part of a selection of 70 cycles ranging from the 1800s to 2022 at the Design Museum in Munich. The frame, designed in a research lab by Italian startup INDEXLAB, was made using their own polymer extrusion process. This particular technique involves shredding and melting discarded polycarbonate items (such as CDs, safety glasses, and water bottles) to create for the conformal RAM (robotic additive molding) process. The technique, led by XGINEERING and GIMAC in collaboration with INDEXLAB, is becoming increasingly popular in the automotive sector because of its speed, waste reduction, and ability to customize unique parts. The resulting frame is transparent, lightweight, strong, and environmentally sustainable.

Photo credits: INDEXLAB

Canyon’s 3D Printed Bike Prototype

Last year, Canyon unveiled the company’s first 3D-printed bike prototype. This was manufactured in three parts by 3D printing service provider Materialise, with each taking six hours to make. Canyon’s goal in developing the bike was to build a more sustainable bike – and that’s where 3D printing technology comes in. That’s because the powder bed fusion solution used reduced the amount of materials needed, bringing the weight of the device to under 2 kg. At the same time, high performance can be guaranteed thanks to the lattice structure of the frame. Another aspect of sustainability is given by the fact that recycled aluminum was used for the production.

Photo Credits: BIKEPACKING

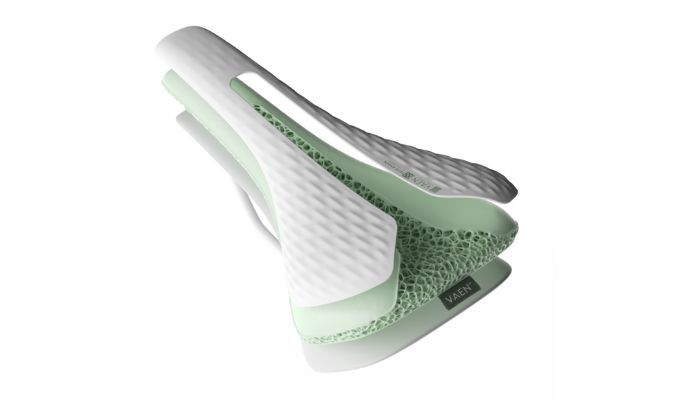

VAEN Develops 3D Printed Bike Saddles That Mimic Nature

Designer Vasi Ganhi has created the VAEN bicycle saddle using 3D printing. With a desire to mimic nature, organic shapes were imitated by using grid-like foam for the middle layer of the saddle. Here, flexible material was used for the 3D printing process and optimized typologically, which ultimately led to the use of a lattice structure for the layer. This is said to be particularly cushioning, while the outer layers are responsible for comfort, breathability and resistance. The use of additive manufacturing makes it possible to customize the saddle to the cyclist, maximizing the performance of the user. In addition, the saddle is available in black, yellow, glass, blue and orange.

Photo Credits: VAEN

What do you think about this ranking of 3D printed bikes? Let us know in a comment down below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Interesting projects ! We could also mention the French Company Nova Ride who manufactured prototypes of stems and crankset in Titanium with innovative designs thanks to Metal AM technology.

Fuckin’ brilliant…thanks for the info. Lots to get excited about here; the future is not looking all bad!

These is really Great, More like working Towards the Future on something Great and Better… These is so Lovely…