PWS Adopts Nikon SLM500 for Additive Manufacturing of Suppressors

Primary Weapon Systems (PWS) is a firearms manufacturer based in Boise, Idaho, that has expanded its metal 3D printing capabilities with the Nikon SLM500. This marks a significant shift towards scaling additive manufacturing for its BDE suppressor line. The system itself will both support the growing demand within the defense market while also cementing the growing role of 3D printing within firearms manufacturing. This investment signals a broader trend with defense sector manufacturers adopting addive technologies to boost both their flexibility and overall innovation.

The SLM500’s quad-laser design delivers a high output without losing accuracy or heavy maintenance, which has increased production of PWS’ complex suppressor components. Director of Engineering at PWS, John Meehan, stated, “We have been at capacity with our current machine for over a year. The SLM-500 is a welcome addition to our capabilities, and I have no doubt it will perform flawlessly and increase our production bandwidth.” The integration of the printer is expected to significantly reduce manufacturing times and enable a swift rollout of PWS’s next-generation suppressor models.

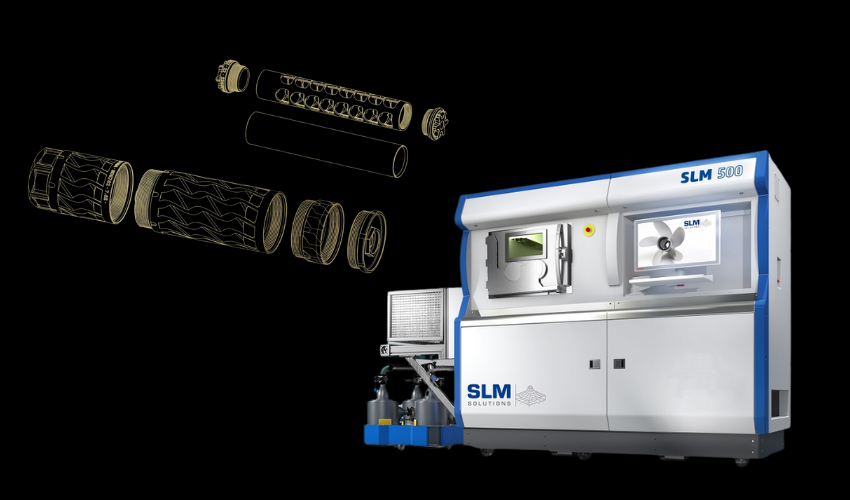

The Nikon SLM500 Dual Laser Printer System (Credit: Nikon SLM Solutions)

Since PWS acquired the SLM500, they haven’t just increased their capacity, but they have also unlocked new engineering capabilities. The company announced that it has expanded its portfolio to include materials besides titanium, such as Haynes 282, a high-temperature alloy that is already present within the aerospace and defense sector. This allows for new designs that can endure high heat and pressure during use. Meehan noted, “In the end, the SLM500 provided the best of both worlds. The quad lasers allow high production outputs for PWS’s BDE suppressor line while delivering a competitively priced finished product.“

PWS announced that the SLM500 was installed this past June at their 65,000 square foot facility in Boise. This location is where most firearm components, such as receivers and handguards, are currently produced. With the addition of 3D printing, the team expects a more streamlined process in manufacturing and a push forward in new designs that utilize additive manufacturing. The in-house integration of metal AM will allow for a tighter design of the iteration loops while reducing dependency on third-party suppliers. This allows for PWS to respond more quickly to both market and consumer demands with high-volume orders or customized suppressor models.

The inside of the Nikon SLM500 Printer (Credit: Nikon SLM Solutions)

While 3D printing continues to break new ground in the aerospace and automotive industries, its adoption signals a growing shift of preference towards additive manufacturing. Additive manufacturing gives companies like PWS the ability to design for function, not just manufacturability. The SLM500 is designed specifically for high-paced environments, providing precision, speed and scalability that meets the demands of the industry. For Nikon SLM Solutions, the company behind the SLM500, the success of its printer at PWS may serve as a jumping board for more defense manufacturers to employ additive manufacturing.

How do you see additive manufacturing changing the future of the defense sector? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. For more 3D printing news in the aerospace and defense sectors, check out our dedicated page HERE.

Cover Photo Credits: Primary Weapon Systems & Nikon SLM Solutions