Researchers creates prototype of a 3D printed bionic eye

The 3D printed bionic eye would be more effective

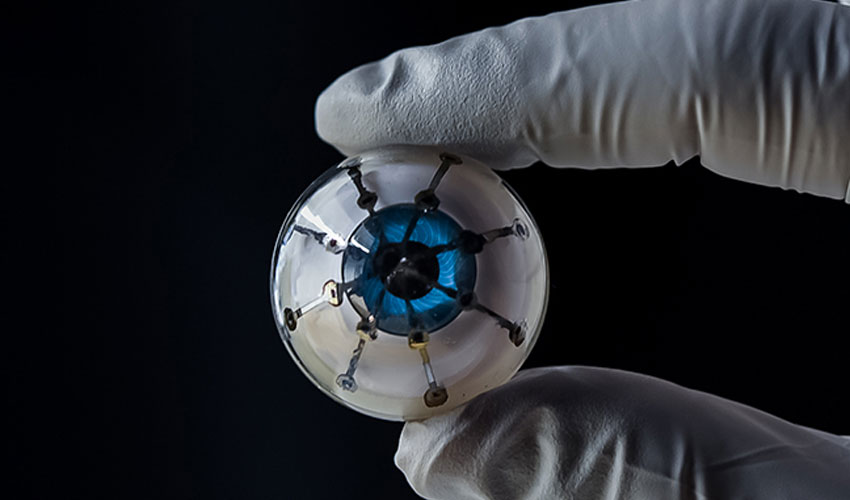

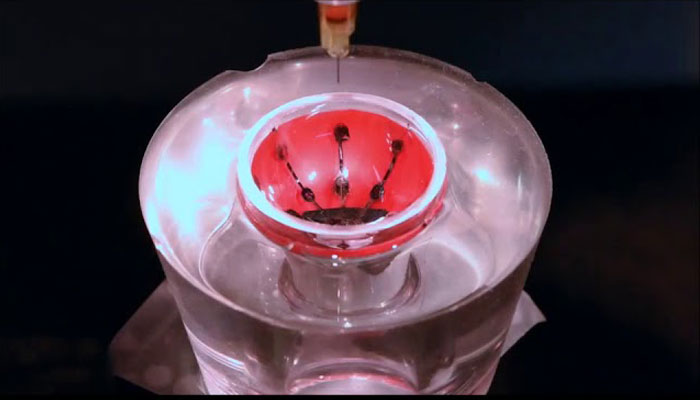

This group of researchers are already fans of 3D printing and at the origin of many innovative projects, such as direct printing of electronic components on the skin. This time around the interest fell towards eyes and wanting to test the additive manufacturing on rounded surfaces. They therefore used a 3D printer capable of extruding silver nanoparticle ink onto a hemispherical glass dome. According to the team, the ink remained on this surface and dried steadily, instead of flowing along the dome.

The researchers explain that they then used semiconductor polymer materials to print photodiodes that convert light into electricity. These were placed in the glass dome on a plastic film. The whole process would have taken about an hour. McAlpine claimed that the conversion of light into electricity obtained with 3D printed semiconductors was 25% more efficient.

3D printing on the rounded surface

“We have a long way to go to routinely print active electronics reliably, but our 3D-printed semiconductors are now starting to show that they could potentially rival the efficiency of semiconducting devices fabricated in microfabrication facilities” said McAlpine. “Plus, we can easily print a semiconducting device on a curved surface, and they can’t.“

The next steps in the project are to create prototypes with more and more efficient light receivers. Researchers would also like to find a way to print on a flexible hemispherical material. This to be implanted in a real eye. You can find more information on the official website of the university and in the video below:

What do you think of UMN’s project with a 3D printed bionic eye? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news in 3D printing send straight to your inbox!