PrintWatch Detects 3D Printing Errors to Optimize Time and Materials

U.S.-based Printpal has announced the official release of PrintWatch, a software and API that can detect printing errors during the part manufacturing process and take appropriate actions. The solution can stop printing in progress, warn the user of a defect or reduce an extrusion temperature that is too high. PrintWatch is also able to monitor the status of the 3D printer in question, making it easier to schedule any maintenance operations. This solution can be integrated with OctoPrint and is available via a monthly subscription.

Managing a print, regardless of the technology used, can be complex, especially when you have several 3D printers running at the same time. Errors happen quickly, such as nozzle jamming, stringing, over-extrusion, etc. Often, you have to restart the printing process, which means using more material than expected and, above all, losing machine time. There are currently some solutions to facilitate this management: remote monitoring applications, integrated cameras, filament detection end, etc. In fact, we presented this intelligent AIMS box, capable of detecting the most common errors simply by being placed on the machine.

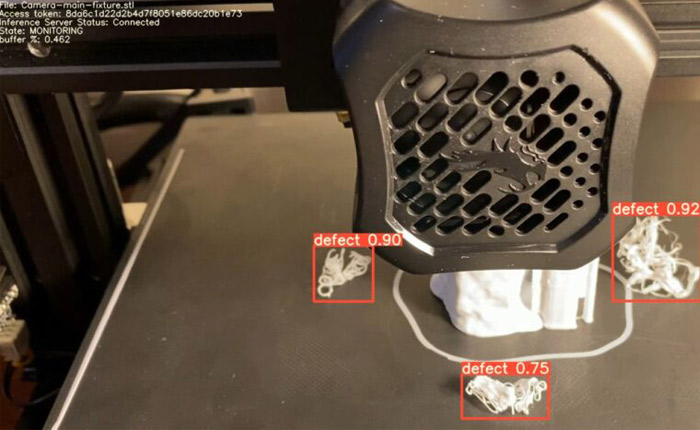

What the machine learning model sees (photo credits: Printpal)

PrintWatch does not rely on a physical system but on software and an API. The company Printpal, which specializes in machine learning and artificial intelligence, uses a series of algorithms that adapt to the user’s 3D printer. The user installs the software on his computer or on a Raspberry Pi – the configuration is quick and easy – and enters his printing parameters. For example, he can choose the preferred detection sensitivity.

In concrete terms, when the software has spotted a defect, it tracks it in order to evaluate its severity. Depending on the situation, it can stop the machine or simply send a notification to the user. The accuracy rate is evaluated at 93%. How does it work? Printpal explains, “In order to detect defects in real-time, PrintWatch takes the video stream of a camera fixed onto the printer’s print area and runs it through a Machine Learning model that can detect defects of various sizes, shapes, colors, materials, lightings, and settings. When a defect is positively identified, PrintWatch then begins to track the defect to see how it develops. If it is clear that the defect is getting worse, PrintWatch takes action. This tracking system helps prevent any false-positives from triggering action from the software.”

These machine learning models are built on a cloud, so all you need is an internet connection to access them and run the calculations. PrintWatch is also accessible via Octoprint. Finally, you should know that another version is under development, a version that would work only via a local network, ideal for manufacturers facing possible security issues. As for the price, it costs $9 per month for a 3D printer for the Premium version – if you want to use a second machine, add $4. A one-month trial version is available for the more curious. Find more information HERE.

What do you think of this solution? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.