Inside the World’s First Successful 3D Bioprinted Human Cornea Transplant

In October 2025, Rambam Health Care Campus in Haifa, Israel, marked a world first with the successful transplantation of a fully 3D bioprinted corneal implant, created entirely in the lab from living human cells. Developed by Precise Bio, the implant was produced using a platform capable of expanding a single donor cornea into up to 300 transparent, layered corneal structures designed to replicate the function of a healthy human cornea without the need for additional donor tissue. The procedure, performed at the Rambam Eye Institute as part of an ongoing Phase 1 clinical trial, restored vision in a patient who was legally blind in the treated eye. This milestone represents a significant step forward in addressing the global shortage of donor corneas and offers new hope to millions affected by corneal blindness. To better understand the technology and its implications, we spoke with Aryeh Batt, CEO and Co-Founder of Precise Bio.

3DN: Could you introduce yourself and share what led you into 3D printing and co-founding Precise Bio?

CEO and Co-Founder Aryeh Batt

My professional background is physics, mainly in the electro-optics field. I have held positions in the Israeli hi-tech industry from R&D to executive management and led multi-disciplinary products from development to sales and marketing. I developed a unique 3D printing technology that can ‘print’ human cells at high viability, enabling the structuring of human tissue and organs comprised of human cells and natural materials mimicking the functionality and structure of the human tissue. When I understood the revolution we can bring in healthcare, I decided to establish Precise Bio with Dr. Anthony Atala, the director of the Wake Forest Institute of Regenerative Medicine (WFIRM), a leader and pioneer in the tissue engineering arena, and Prof. Shay Soker (also from WFIRM), a molecular biologist and a leading scientist in the field.

3DN: What is Precise Bio’s mission?

Precise Bio envisions a future where patients no longer wait for life-saving transplants, and unmet critical therapeutic needs are solved using Precise Bio’s natural, hyper-accurate bio-fabrication technology. The company fabricates natural tissues for transplant in patients, addressing needs where there is a lack of donor tissue or in cases where there is a therapeutic need. Replacing a damaged tissue with a new bio-fabricated tissue can solve the unmet need.

3DN: Could you tell us about the technologies and materials Precise Bio utilizes?

Precise Bio is a multi-disciplinary technology platform, combining cell biology, biomaterials, bioengineering, engineering disciplines as SW, mechanics, physics, and electronics. Bringing all of these technologies to an integrated platform enables the bio-fabrication of clinically viable tissues. As a directive, Precise fabricates the tissues and organs from human cells and natural materials. The cell’s source is different from tissue to tissue. There are tissues where the cells are from primary cells, and in other cases, from stem cells, iPSCs, or hESCs. The collagen we use in our tissue is human-derived GMP-grade collagen.

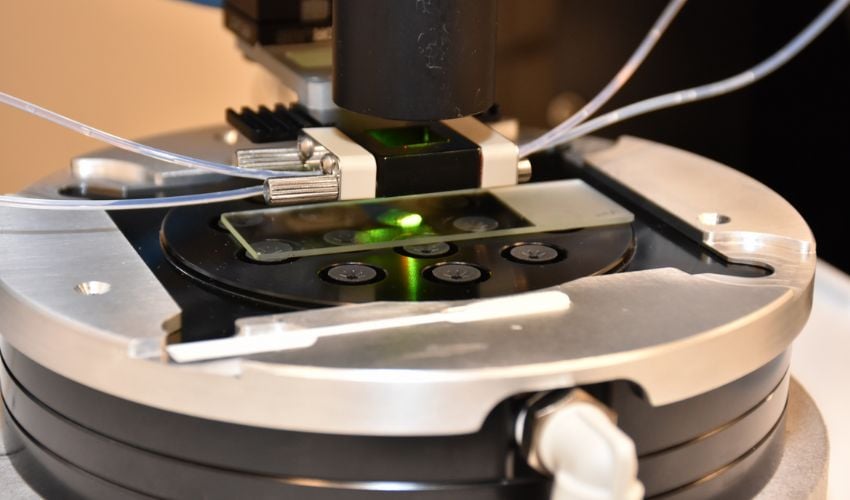

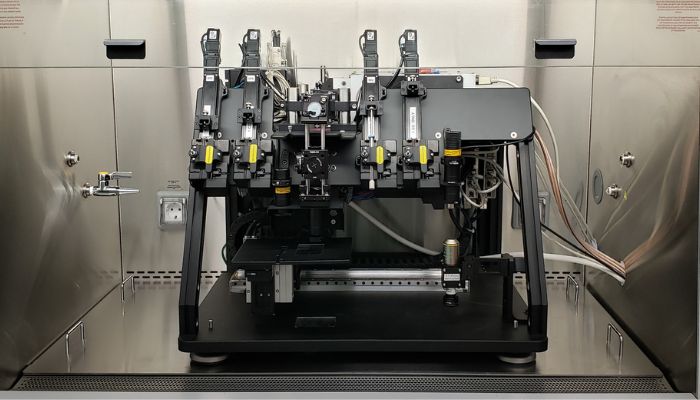

Precise Bio’s technology allows them to generate complex tissues in a highly reproducible manner.

3DN: Precise Bio recently made headlines for the first 3D printed human cornea transplant. Can you tell us about that process?

The process of bringing a 3D bioprinted tissue or organ to the clinic starts with the development of the tissue. The main components are the cell biology and the ECM, the structural material of the specific tissue or organ. The process starts in the lab and includes development and in vitro testing, moves on to the preclinical stage, in vivo testing, and is followed by the phases of clinical development: human transplant and study. In addition to the development of the tissue, the production processes, quality control, and regulatory path are addressed. To bring the specific tissue, with the delivery device, to the hands of the clinicians, all these processes must be synchronized, combined, and approved by the regulatory authorities.

3DN: What are some of the challenges you faced in producing this cornea, and how did you overcome them?

One of the main challenges in tissue development is establishing a cGMP production line fully quality-controlled and approved by regulatory authorities. There is a significant gap between engineering and manufacturing a tissue in the lab, and maybe writing an article, to produce a clinically worthy tissue approved for clinical use. The gap is not just time and money, but it requires a different mindset and capabilities to utilize a qualified supply chain that can be commercialized and approved by the regulator.

3DN: What makes Precise Bio’s technology different from other bioprinting companies?

Precise is not just a bioprinting company. We do have a unique printing technology that enables SCR (Single Cell Resolution), a feature that can mimic the exact anatomical structure of the human tissue. But this is ‘just’ the manufacturing tool. Above the printing, the uniqueness of Precise is the combination of a multi-disciplinary platform that combines cell biology, bio-materials, engineering disciplines, quality control (QC), quality assurance (QA), regulatory affairs (RA), and clinical directives.

3DN: Looking ahead, what are the long-term goals or areas of innovation you’re most excited about for Precise Bio?

Precise has started with the first product in the clinic – the cornea, this will be followed by additional ophthalmic tissues, but we will be active in additional fields such as cardiology, orthopedics, nephrology, and more. Our technology platform enables the development and fabrication of life-saving tissues and organs. This is the ‘holy grail’ of regenerative medicine and tissue engineering.

Precise Bio uses a 4D printing platform that enable bio-fabrication of tissues.

3DN: Any final thoughts for our readers?

Precise is changing healthcare as it is known today. Natural spare parts that are fabricated and supplied on demand are no longer science fiction but a reality demonstrated with the first cornea transplant done several weeks ago.

What do you think of Precise Bio’s work? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE.

*All Photo Credits: Precise Bio