Post-Processing Techniques That Allow Color in 3D Printed Parts

Two key benefits of additive manufacturing are the greater design freedom and customization that are possible when creating parts. However, not all 3D printers have the capability to create multicolor parts or parts with special finishes. For this, post-processing systems are a key tool in obtaining final models with the desired appearance. We have already seen above the basics of post-processing in 3D printing, as well as some of the most commonly used techniques, such as cleaning or surface finishing. In addition, there are also post-processing methods that add color to 3D printed parts. In order to better understand the different coloring or dyeing techniques, we have created this complete guide to the different options available.

We will address not only the production of full-color, 3D printed parts, but also the post-processing techniques available in 3D printing to achieve metallic finishes. Specifically, we will know in detail three of the main post-processing methods for color or special finishes: painting, dyeing and plating. Some of them will be more suitable for some parts or others, depending on the technology and the material used. Even so, it is always recommended to perform certain steps prior to the surface treatment of the parts. This is done mainly to ensure that the printed models have a smooth finish, free of imperfections and roughness. Once a uniform surface is achieved, we can start the treatment of the 3D printed parts to give them color and other special finishing.

Before applying color to the parts, it is recommended to perform the appropriate post-processing to achieve a smooth and uniform surface

Paint

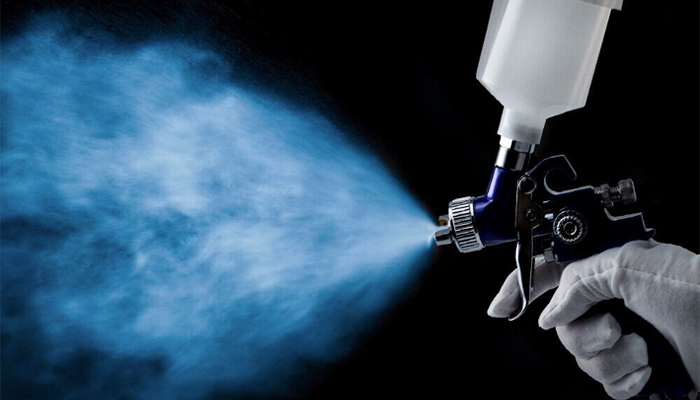

When it comes to applying paint to 3D printed parts, there are two ways to do it: with paintbrushes, or with a spraying tool. First, using brushes and acrylic paint is a cheaper solution, but will require much more time to achieve the desired result. The main benefit of this technique is that you can combine a multitude of shades in different parts to get multicolored pieces. On the other hand, we can also use spray paint or spray paint guns to create a coating on the surface of the parts. This technique is commonly used even on parts machined using traditional manufacturing processes. To do this, it is recommended to clamp the part with wire or place it on some support for a more comfortable process. Then, position the spraying tool at a minimum distance of 15 cm from the model and start painting the part firmly until the entire surface is covered.

Although these methods are different, they can also be used complementarily, starting with a general spraying and ending with the use of brushes to achieve a higher level of detail. In both cases, a subsequent varnish may be applied to achieve a glossier finish, although this will mean a longer turnaround time for the parts. However, the main disadvantage of painting is that the paint coating is purely superficial as it is not able to penetrate the part. Therefore, if it is scratched or worn, the initial color of the 3D printed part will be exposed. In addition, it should be taken into account that the more layers of paint and varnish applied, the thicker the surface of the piece will be.

Dyeing

Dyeing is another post-processing method for 3D printing that allows users to obtain colored parts. Unlike the previous method, where a layer of paint is applied to the part, dyeing colors the material much more deeply. This ensures that models with more vivid colors are obtained, while avoiding peeling and scratching of the paint. In addition, the absence of a thicker surface of the outer layer prevents the loss of details, thus respecting the original design of the piece. It should be noted that this post-processing technique for color is only compatible with powder bed-based 3D printing technologies and polymers (SLS, MJF, SAF, etc.). This means that the most commonly used compatible materials will be TPU, PA11, PA12 and Alumide (a nylon-based material filled with aluminum powder), among others.

The dyeing process consists of immersing the 3D printed parts in a hot dye bath before removing and drying them. As the parts are in direct contact with the color pigment, the dye completely penetrates the layers of the 3D printed parts, reaching even the most inaccessible recesses. This allows for a colorful and uniform finish regardless of the geometric complexity of the model. An important thing to keep in mind is the initial color of the material used, as it will influence the dyeing performance. In other words, coloring white 3D printed parts, where it is easier for the pure pigment to penetrate the surface, will not be the same as coloring initially gray parts, which already have a base color range.

In the dyeing process, the pigment penetrates the part to give it a purer color (photo credits: Stratasys / DyeMansion)

Plating

The plating process consists of placing a thin layer of metal on the surface of the parts to obtain a shiny, metallic finish. Despite the metallic result, the initial part can be 3D printed with polymers, metals or other materials. Gold, silver and nickel are the most commonly used plating finishes. However, there are other options available, such as plating, chrome plating and electroplating. As for the process itself, there are several ways of plating. Still, the most common one consists of coating the uniform surface with a sheet that is then heated and pressed onto the part to fix it. Other methods available include electrolytic nickel plating, tin plating, copper plating, vacuum vapor deposition, or cathodic deposition.

Pieces with different metallic and shiny finishes (photo credits: Metalizz)

What do you think of the different post-processing techniques used in 3D printing for full-color parts? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: TCN