Polymer 3D Printing Is Revolutionizing the Production of Tooling Fixtures

Recent developments in additive manufacturing with high-performance polymers, particularly when it comes to improved dimensional accuracy and surface quality, are enabling the adoption of this technology for the production of more durable tools. Indeed, AM is now making it possible to reduce lead times, labor and costs for tooling as compared to machining.

Major companies in industries like automotive and aerospace—such as Ford and Moog Aircraft Group, among others—have recognized this. As have smaller businesses like machine shops, which are increasingly using technology in their production processes. Today, we are sharing real examples of companies that have chosen the technology from additive manufacturing leader Stratasys to make tooling fixtures faster and at a lower cost. We took a closer look to understand how 3D printing can help solve common tooling challenges and how these companies are already using the technology and seeing its benefits.

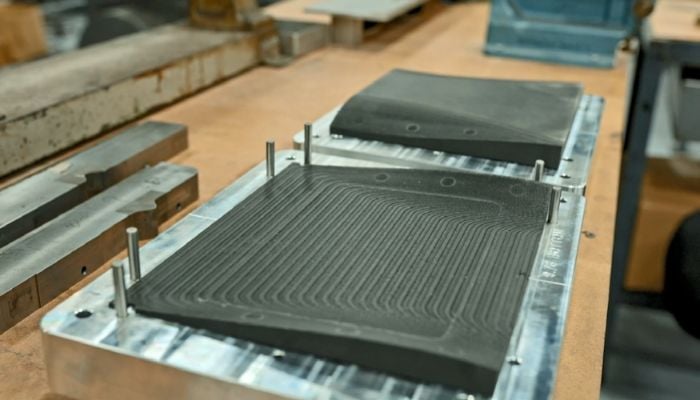

East/West Industries prints metal forming dies using the Fortus 450 3D printer and Nylon 12CF, achieving 80% cost savings and a production time of 1 week, compared to 8 weeks for machining.

The Main Challenges of Tooling and How AM Can Overcome Them

Traditional machining methods for creating tooling fixtures, for example milling, welding or assembly, are well-established but often slow, costly and limited. Common challenges include shortages of skilled labor (particularly CNC operators), long lead times, high costs (especially for low runs or custom tooling), design constraints and issues related to inventory management. In all these cases, which can stop or slow production, the interest of companies is to find more agile and efficient solutions. This is where additive manufacturing comes in.

For complex or low-volume tooling, AM enables the creation of equipment with the needed dimensions at a reasonable cost. Additionally, AM overcomes design limitations inherent in traditional methods. Conventional tooling often favors ease of machining, leading to tools that may not be ergonomic, lightweight or otherwise optimized. In contrast, AM allows for the design and printing of tools with customized geometries that better suit specific tasks and operators.

Conventional tooling fabrication also entails long lead times and high costs. However, 3D printing, whether done in-house or through external partners, can produce the same part in a matter of hours at significantly lower costs.

Physical storage space and related costs, along with end-of-life disposal, are also often a concern. By using 3D printing, on-demand production becomes more feasible, making it possible to store old tools in digital libraries, thus saving storage space, manufacturing time and costs.

Finally, attracting and retaining skilled workers remains a persistent issue in manufacturing. Additive manufacturing provides an efficient alternative. The effort required to learn and operate 3D printers, particularly FDM systems, is minimal compared to the skills needed for machine tool and CNC operators. Moreover, 3D printers do not require supervision during the printing process.

Are Engineering-Trade Thermoplastics a Suitable Alternative to Machined Metal Fixtures?

So far, we have covered the general advantages of using 3D printing over traditional methods in producing fixtures. But what about materials? Well, AM makes it possible to produce strong tools, including those traditionally made with metal, using engineering-grade thermoplastics. These polymers are exceptional because, while not metal, they still have the required properties for these applications. It should however be noted that the specific application for the part is critical to keep in mind while choosing the technology and material.

General Motors printed with an FDM rear hemming tool, resulting in 56% weight reduction, 77% lead time savings and 74% cost savings compared to the aluminum version.

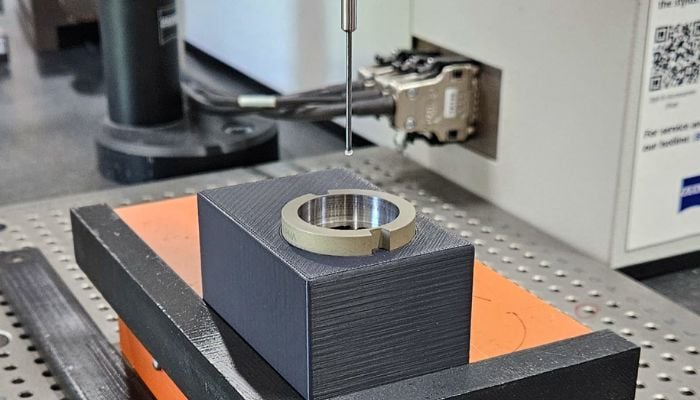

In general, technologies such as FDM and DLP are well-suited for many unique tooling applications, as they are compatible with a wide range of versatile thermoplastics and photopolymers, including those that boast remarkable mechanical properties. Contrary to common misconceptions, these materials provide excellent strength and hardness. In addition, when greater strength and stiffness are required, carbon fiber-filled materials such as ABS-CF10, FDM® Nylon-CF10, and FDM® Nylon 12CF offer several solutions that can meet these needs. Some thermoplastics, such as ASA, also offer an advantage over metal for making coordinate-measuring machine (CMM) substrates due to higher thermal stability.

Case Studies

Let’s look at some case studies, starting with Ford Motor Company, which adopted FDM 3D printing because it needed a lighter, more ergonomic window glass installation fixture. Engineers chose Stratasys’ FDM technology and Nylon 12CF to make a tool that was lighter while retaining strength and rigidity. 3D printing also allowed Ford engineers to internally reinforce the fixture with a higher density of material where strength was needed, while keeping lower density in non-critical areas. A feat that is not possible with a machined tool. The end result was a fixture that was 15% lighter, 70% cheaper and easier to use than its metal counterpart.

The Moog Aircraft Group company, which designs flight control systems for commercial and military aircraft, has also turned to FDM 3D printing to improve its in-house CMM inspection capabilities. Previously, tool-steel fixtures made by third party suppliers were used, however these represented a significant expense and required lead times of several weeks. Today, Moog is able to 3D print a dedicated CMM holder for each machined component, achieving significant benefits in terms of speed of production and cost reduction. In some cases, savings have exceeded 80% compared to traditional fixture production.

Another case in which AM resulted in time and cost savings is in the production of a tool by Valiant TMS, a company that develops intelligent manufacturing automation systems for the automotive and aerospace industries. The company needed a hand tool that would attach an auto A-pillar door latch. To be effective, this part required a combination of operator ergonomics, strength and minimal weight.

The engineers decided to make the tool with 3D printing, as this solution met the requirements better than a machined metal alternative. A key aspect of the ergonomic design was to achieve an extremely smooth, defect-free surface finish using a material that could provide adequate mechanical strength. Valiant TMS’s AM lab printed the tool using Stratasys’ Origin 3D printer using P3™ DLP technology, which provides a surface finish similar to injection molding, and chose Dura™56 material for its high printing speed and excellent impact resistance. The result was a 78% cost reduction and 79% shorter printing time compared to other additive processes.

German Aerospace Center builds functional prototypes of a robot able to withstand the extreme conditions of Mars.

In conclusion, 3D printing with engineering-grade thermoplastics now enables the production of faster, more cost-effective, less labor-intensive tooling that requires less labor while also allowing for customization. In addition, 3D printing allows for greater flexibility in the choice of plastic materials, the creation of more complex geometries and shorter processing times. Once the initial roadblocks, which arise due to lack of experience and a fear of adopting a new technology, are overcome, it is possible to leverage the technology to save costs, increase production, and obtain efficient tools quickly. You can learn more about how polymer 3D printing can revolutionize the production of your tooling fixtures and Stratasys’ technology HERE.

Have you already adopted 3D printing for tooling production? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

All Photo Credits: Stratasys