Researchers Create Polycatenated Architected Materials (PAMs) for 3D Printing

Recent advances in materials science have led to new solutions in architecture and design. In a recent example, a team of researchers in California has developed polycatenated architectural materials (PAMs), which are capable of interweaving to form unique 3D structures. These materials can be used as wireframe elements to create 3D structures with interesting properties in a number of different sectors, including engineering and design.

To be precise, this new type of material was developed by a team of engineers from the California Institute of Technology (Caltech), in collaboration with Lawrence Livermore National Laboratory and Princeton University. Neither granular nor crystalline, it can be either fluid or solid depending on the stress that is applied to it. Made with 3D printing, these structures offer a new way of rethinking traditional designs and creating objects with surprising physical properties.

PAM Materials Are Suitable for Many Applications and Sectors

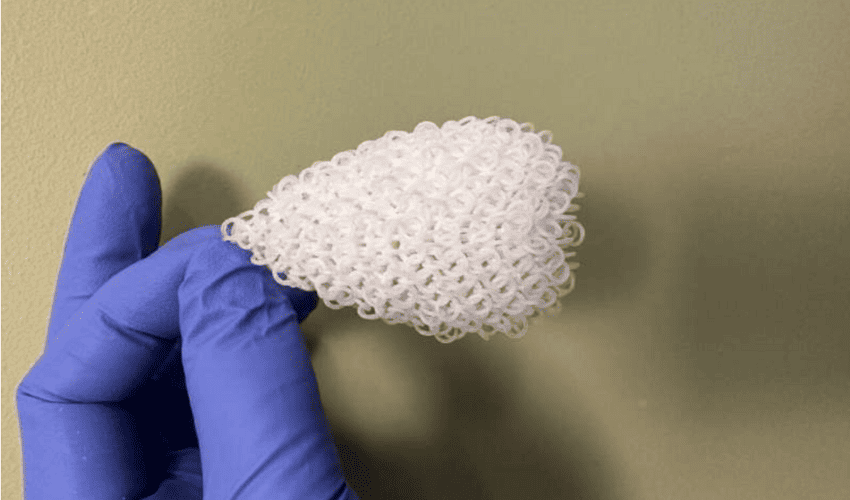

PAMs are materials with a unique structure, similar to chain links, but used in an original way. Their design stems from research into how different elements can be linked together to form complex structures. In a study published in Science, the researchers detail not only how these materials are made, but also the interesting properties they observed during their tests.

3D printing is essential for creating PAMs. With this technology, researchers can manufacture complex structures, such as rings, hexagons or specific geometric shapes, with great precision. This opens up a wide range of applications, such as architectural projects or materials for space, which can be modified as required.

They experimented with different ways of assembling these materials, and tested the characteristics of the resulting structures. They found that some objects could be flexible like a liquid when not handled, but became hard as soon as pressure was applied. Other printed structures repelled each other and, once connected, could contract or bend, rather like muscles.

Researchers are already exploring futuristic applications for PAMs, such as the creation of materials for space. These materials would be flexible and able to adapt to changing conditions, while reducing the weight of structures, which is essential for space missions. You can access the study HERE.

What do you think of these polycatenated architectural materials (PAMs)? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.