All You Need to Know About PETG for 3D Printing

PETG, or polyethylene terephthalate glycol, is a thermoplastic that is one of the most widely used polymers in additive manufacturing. Notably, it is a popular choice for filaments and fused deposition modeling because it combines both the simplicity of PLA 3D printing and the strength of ABS. It is an amorphous plastic, which can be 100% recyclable, with the same chemical composition as polyethylene terephthalate, better known by its acronym PET. To better under the material, the following guide outlines the characteristics of PETG, what you need to know for 3D printing with it, its main applications and manufacturers.

Production and Characteristics of PETG

To understand PETG, it’s important first to look at PET itself. PET is a well-known material in the industry, estimated to grow from USD 52.94 billion in 2024 to USD 109.63 billion by 2032, because it has been used in bottle manufacturing and packaging since the 1990s, replacing PVC. It also allows the production of synthetic fibers for clothing. However, it is not common to use pure PET in 3D printing. Rather, glycol (G) is added to PET at a molecular level, allowing the material to have greater strength and durability while making it more flexible.

Photo Credits: Thad Zajdowicz, CC0, via Wikimedia Commons

PETG is therefore a copolymer, combining the properties of PET and glycol. The addition of glycol reduces overheating issues with PET (which prevents it from being used for additive manufacturing as it is) as well as reduces its brittleness. Its hardness, impact and chemical resistance, transparency and ductility are among the main characteristics of PETG. It is an easily extruded material with good thermal stability, particularly appreciated for its compatibility with food.

3D Printing With PETG

Regarding printing parameters, PETG has an extrusion temperature between 220° and 260°C and it is advised to use a heated printing bed between 75-90°C. An ideal printing speed is 40-60mm/s. It is not recommended to use supports with PETG because it can stick too well to itself, making them difficult to remove after printing. Still, the material is relatively easy to print, a bit more difficult than PLA but with good properties.

That being said, there are downsides to the material. Notably, it requires a heating plate to avoid the warping effects that can occur with PETG – even if the warping rate is low, it is better to use a BuildTak sheet to ensure the material grips. It is also more prone to scratches than PLA. Finally, it can quickly take moisture and must be stored in a cool and dry environment. Furthermore, it is highly viscous and can clog print heads.

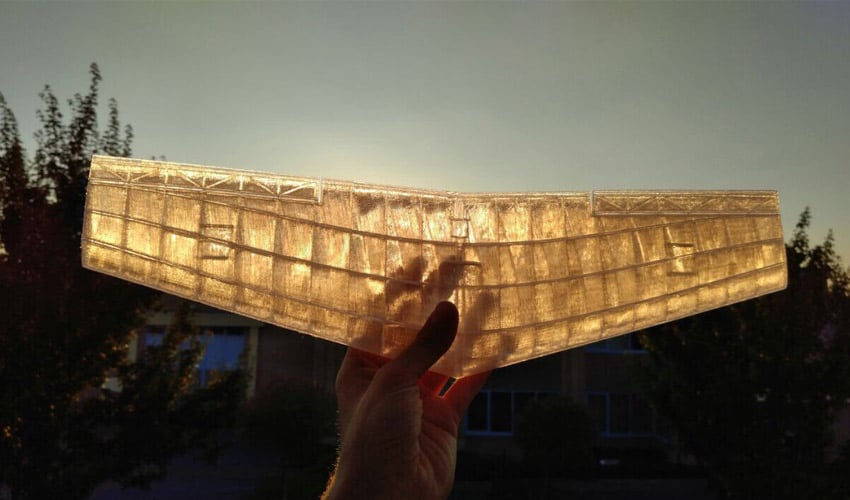

PETG is known for its hardness and transparent appearance (Photo credits: Taulman3D)

Applications With PETG

PETG can be used for several different applications. The first that comes to mind is the food industry. Due to its relation to PET, PETG is water-resistant and can be in contact with food according to the FDA. This makes it especially suitable for food packaging. And that’s not all—PETG is suitable for dental aligners, medical equipment and prostheses, thanks to its sterilizability.

As expected, PETG is also widely used for prototyping, thanks to its relative cost-effectiveness and adequate properties. Additionally, due to its heat and chemical resistance, it can even be used in more durable applications such as tooling, testing components or end-use parts for machines.

The Main Filament Manufacturers

Most filament manufacturers nowadays offer this material: Formfutura, ColorFabb, 3DXTech, Innofil3D, Polymaker or even proprietary brands such as Zortrax. In terms of format, like other filaments, there are 1.75 or 2.85 mm diameter spools, with different weights according to needs. Note that PETG is often reinforced with carbon fibers, which increases the rigidity of the part while optimizing its final weight. Nanovia, for example, offers this solution in its range of filaments. It has also developed an aramid-fiber reinforced PETG that reduces the fragile appearance of the PETG while increasing its stiffness and strength.

PETG can be reinforced with carbon fibers (Photo credits: Fusion3 Design)

Finally, on the price side, be aware that it is a little more expensive than PLA. It costs between $35 and $40 for a classic 750-gram PETG spool. Of course, some brands will be more or less expensive. For example, a carbon fiber-reinforced PETG will increase the price of your spool.

Did you learn something about using PETG for 3D printing? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news in 3D printing sent straight to your inbox!

*Cover Image Credits: BlackBelt3D

Hi Carlota V.,

Thanks for your article. What dyes and pigments are usually used or are compatible to color PETG filaments? Are they Vat dyes, acidic or basic dyes? Are some dyes incompatible with PETG filament, such as solvent dyes? Thanks!

It’s impressive how PETG combines ease of use with durability, making it a great choice for a variety of applications!