Personalized Medicine Thanks to Volumetric 3D Printing and Semi-Solid Extrusion

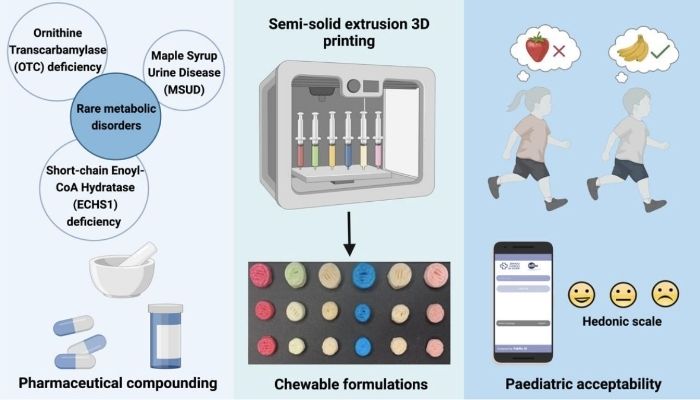

3D printing is transforming drug manufacturing, offering customized solutions that improve treatments and the patient experience. Traditionally, bespoke medicines have been prepared using magistral preparations, a manual, laborious and error-prone process. However, 3D printing is emerging as a promising technology in this field, overcoming these constraints by offering the possibility of producing medicines perfectly tailored to each patient’s needs. A recent study led by Lucía Rodríguez Pombo, a researcher at the University of Santiago de Compostela (USC), confirms the effectiveness of 3D printed personalized medication, particularly for pediatric patients.

The study, titled Clinical Implementation of 3D Printing for the Preparation of Personalized Medicines, focuses on the application of 3D printing in a clinical context for medicine manufacturing. Under the supervision of Professors Carmen Álvarez and Álvaro Goyanes, Lucía Rodríguez Pombo explores two main technologies: semi-solid extrusion and, for the first time in the pharmaceutical field, volumetric 3D printing.

The 3D-printed drugs are designed with the patient’s needs in mind, and of course their taste preferences.

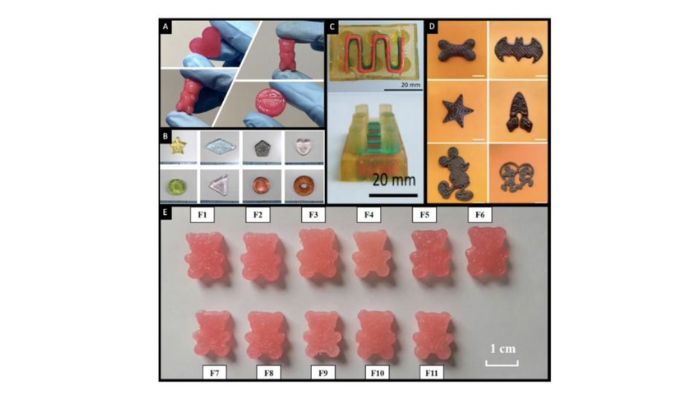

As part of this study, both techniques were evaluated for potential implementation in hospitals, highlighting their ability to produce personalized pediatric drugs, with shapes, flavors and dosages tailored to the specific needs of each patient. In particular, for the first time, two different formulations were integrated into a single printed drug, helping to improve compliance in children aged 6 to 14.

Semi-Solid Extrusion and Volumetric 3D Printing

Looking at the results obtained with both techniques, it becomes clear that they represent a significant advance in the field of personalized medicine. The study demonstrated that semi-solid extrusion (SSE) can be used to print tablets to treat rare diseases, such as (MSUD), an uncommon hereditary metabolic disorder. Furthermore, the use of volumetric 3D printing “was a milestone in the pharmaceutical field, as this technology had never before been tested for printing medicines,” Lucía Rodríguez Pombo explained in her article. The doctoral thesis reveals that volumetric 3D printing can produce high-quality personalized drugs in just a few seconds.

Semi-solid extrusion has been used to print drugs in a variety of forms, including gelatin and chocolate.

As well as focusing on customization, the study represents an important step forward in the regulatory and clinical implementation of 3D printing. Thanks to technologies such as semi-solid extrusion and volumetric 3D printing, it could pave the way for a new era of more effective drug manufacturing. These innovations not only optimize the use of resources but also facilitate adherence to treatment by creating medicines that are more attractive and convenient to administer, particularly for young patients.

The thesis also discusses the regulatory implications and opportunities for clinical integration of these technologies in hospitals, with a view to their wider adoption in healthcare. To find out more, you can read the press release from the University of Santiago de Compostela, in Spanish, HERE.

What do you think of this method for 3D printing medication? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! If you are looking for more 3D printing in medical and dental content, check out our dedicated page HERE. Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Lucía Rodríguez Pombo/University of Santiago de Compostela