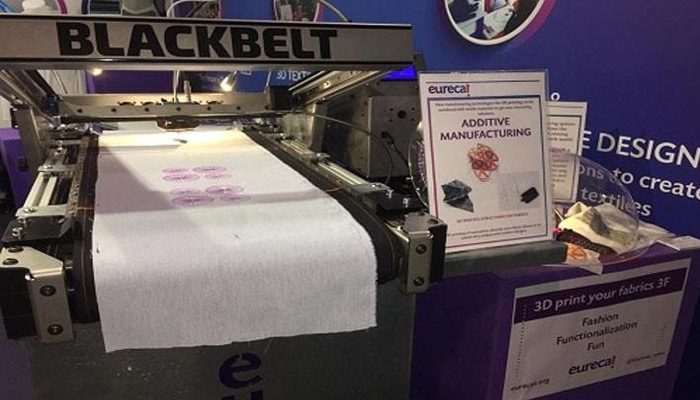

A 3D printing method to personalise textile to infinite length

The Catalan technology centre, Eurecat, recently presented an innovative application of continuous 3D printing to personalise textile. Indeed, by adapting the Blackbelt machine, it can 3D print patterns on fabrics, and this in a seemingly infinite way. The 3D printer in question is based on the use of a conveyor belt which, unlike a conventional tray, allows uninterrupted printing. This could have an impact on the textile industry as this new design method will offer greater customisation possibilities, even on very long fabrics, and will also make it possible to automate the process as much as possible.

Additive manufacturing affects many sectors, industrial or not, and has an impact on manufacturing methods as we know them today. Even if it is not yet possible to 3D print textiles, the fact remains that the fashion industry is evolving with the development of 3D technologies. These offer personalised products, a key criterion for consumers looking for uniqueness, but also more complex and more comfortable if we take the case of shoes. Eurecat wanted to focus solely on textiles and 3D printing, offering a clever way to personalise any fabric.

The Blackbelt 3D printer is based on the use of a conveyor belt

3D printing to personalise the textile

As the process is patent pending, Eurecat is quite discreet in how it works, but the company says it can customise any type of fabric, in any colour, texture or length. The challenge of such a technology probably lies in the adhesion of the plastic to the fabric: how do the successive layers of extruded material attach themselves to the textile? A challenge that the Spanish company seems to have solved, even if some questions remain. Xavier Plantà, Director of Industrial Technologies at Eurecat adds, “This innovative application means that the Blackbelt 3D textile printer is the first in the world to be capable of printing in “infinite length” formats. In turn, this enables 3D printing to move into the world of mass-produced textiles; or in other words, the world of continuous manufacturing.”

Photo Credits: Eurecat

We can imagine that the Blackbelt will be able to create more or less complex patterns on these fabrics which will then be used to make clothing. This new production method could well accelerate the marketing of certain garments, while emphasising aesthetics and personalisation. Virginia Garcia, Director of Eurecat’s Functional Fabrics Department, concludes, “This innovative development makes it possible to create three-dimensional designs and reliefs and print them onto rolls of fabric that will subsequently be used to make garments. It is a pioneering development that contributes to the optimisation of the entire production process.” We have no information about the official launch of such a machine; in the meantime, you can consult the official press release HERE to find out more.

What do you think of this new technology? Do you see its potential? If you want to share some more we might have missed, you can leave a comment in the section below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!