The Paper Pulp Printer replaces plastic with paper waste

The market for Additive manufacturing is constantly growing in everything from the automotive industry to ceramics. However the biggest part is still in more traditional areas like prototyping using plastics. While 3D printing do bring advantages such as being faster and less wasteful than traditional manufacturing, also making it easier to produce on demand. The problem is that the majority of print material used is still plastic, which is one of the most harmful materials for the environment.

This became apparent for designer Beer Holthuis as well, who wondered why there isn’t more sustainable materials for 3D printing. This has led him to develop a method to print with sopping wet paper. The Paper Pulp Printer, is the world’s first 3D printer using paper pulp to replace plastic. Generally the market of materials is growing and there are other alternative materials you can choose from for your prints. However most other are still hybrid materials using PLA as a base.

Beer Holthuis 3D prints with paper waste

Beer Holthuis, from the netherlands, is as a product designer. In this regard, he has crossed path with 3D modeling and additive manufacturing. Through this process, he noticed the worrying amount of plastic being used in the process and started searching for a more sustainable material to replace it.

As the amount of paper waste per person is at around 80 kg yearly, he decided to work with this wasteful and hugely used material. Unlike earlier paper printing techniques such as the 3D printing technology from Mcor, Beer wanted to print directly with the waste material itself. Giving us the world’s first 3D printer to print pulp.

A paper pulp printed speaker

How the Paper Pulp Printer works

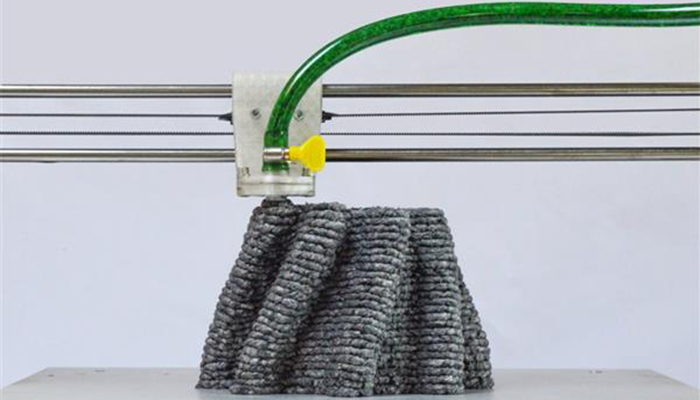

The printer itself are currently pretty straight forward and works overall similar to other 3D printers. For the material he takes regular paper pulp in combination with a natural binder to keep it together. That the binder itself is a natural material as well means that the 3D printed products can continuously be recycled. This creates a closed loop system making it very sustainable long term. He then basically extrudes the paper material through a syringe type extruder from a pressure vessel. The main issue lies with when the printer stops and possible problems with how to keep it from gunking up.

The aesthetics of Paper Pulp Printing

The overall look coming out from the Paper Pulp Printer and texture it produces stands out on it’s own. As Beer Holthuis himself explains, “The design of the printed objects are using the possibilities and beauty of this technique,” And he continues, “The tactile experience, bold lines and print speed results in distinctive shapes. The objects are also durable: Printed paper is surprisingly strong.” The special look of the print gives the designs a bit of personality, bringing something extra to the table.

With everything being low cost in combination with the sustainable aspect there are future potential. This recycling system should be able to take off and work on a high production level.

If you want to see the printer in action, check out the video below:

What to you think of this 3D Paper Pulp Printer? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news in 3D printing send straight to your inbox!