Can Oxygen-Free Production Reduce Oxidation in Metal 3D Printing?

Metalworking and oxygen are like oil and water, they do not mix well. Oxygen is a major disruptive factor in manufacturing, as it causes oxide layers to form. These in turn reduce the quality of a workpiece and lead to faster wear. But what if oxygen could be fully eliminated? Does an oxygen-free environment ensure better results and a long-term remedy? The Laser Zentrum Hannover (LZH) in Germany seems to think so as they researched the impact of oxygen-free production for both brazing and metal additive manufacturing.

This research was done by the LZH via the Collaborative Research Center (CRC) 1368 project “Oxygen-Free Production.” This Collaborative Research Center is made up of researchers from various institutions. In addition to the LZH, institutes from Leibniz Universität Hannover, Clausthal University of Technology and Paderborn University are also involved. The researchers were looking into better oxygen-free production and determine how 3D printing and brazing can be done without oxidation.

To do this, they used an innovative method to tackle the problem of oxidation. During the manufacturing process, they add argon gas with a small amount of silane to the production environment. The silane reacts with the oxygen in the environment and equivalent to an XHV environment. This then has a very low oxygen content and comes close to an extremely high vacuum.

The exclusion of oxygen is much more economical than creating a technical vacuum and could minimize the overall cost of production. The research group tested the oxygen exclusion approach in production and split into two subgroups. One research group focused on brazing without oxygen and the other on additive manufacturing.

Brazing normally involves the use of a flux, which serves to break up the oxide layer on the surface of the material and forces the metal to react with the solder. The new approach of the Collaborative Research Group 1368 “Oxygen-free production” does not use fluxes. The reason behind this was that they are hazardous to health and also have a negative impact on the environment.

Instead, the LZH researchers break up the oxide layer with a continuous-wave (cw) laser beam source. The brazing process then takes place in a silane atmosphere with this cw laser radiation. The oxygen-free environment ensures that the surface does not oxidize between the process steps. The researchers found that their method makes it possible to permanently remove the oxide layers on aluminum alloys. In the next step, the researchers will focus on testing their approach for more challenging compounds and discussing the limits of their approach.

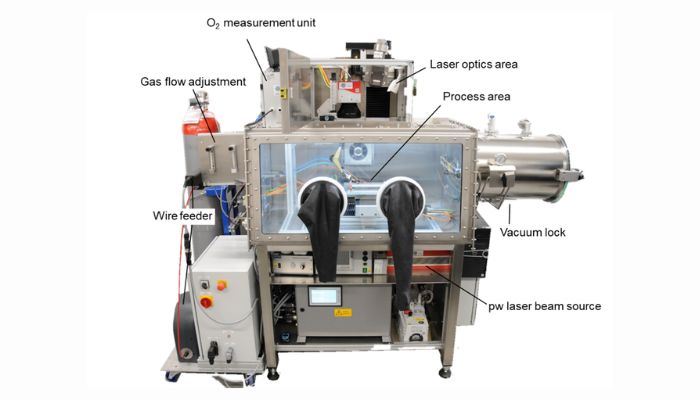

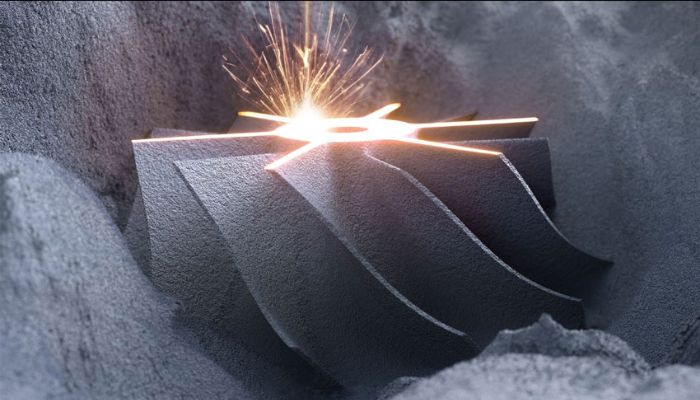

The second subgroup of researchers concentrated on finding out how additive manufacturing could benefit from the oxygen exclusion approach. The focus here was on powder bed-based laser beam melting. The aim was to determine how the powder can be processed in an oxygen-free atmosphere during LPBF and how the process affects the quality of the parts.

To test the approach, they first developed their own pressure system. The process was then tested with a titanium alloy Ti-6AI-4V. A high-speed camera monitored the process and allowed the researchers to better understand the process and determine the influence of oxygen on the process. The initial hypothesis was that the absence of oxygen would lead to a stable process, less spattering and better component properties.

These assumptions were confirmed. Now, the next step is to reduce the moisture in the atmosphere and in the powder to almost zero. The hope is that these actions could further improve the process and the quality of the parts.

Photo Credits: DMG Mori

The initial results were communicated in a press release on January 24 and are extremely promising. The German Research Foundation is supporting the Collaborative Research Center in a second funding period until the end of 2027 with around 10.5 million euros. You can find out more HERE.

What do you think of this oxygen-free production approach? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: LZH