WASP opens orthopedic laboratory for 3D printing of customized medical devices

Italian 3D printer manufacturer, WASP, recently opened a Digital Orthopedic Laboratory, offering their patients the opportunity to have customized medical assistance devices. Thanks to its WASPMed entity, which brings together doctors, researchers and additive manufacturing experts, the Italian company will be able to develop affordable medical solutions. This includes prostheses and orthoses.

WASP (World’s Advanced Saving Project) touches many industries, including the construction sector, with their Italian village. The Italian manufacturer also offers medical solutions created using 3D technologies, with its WASPMed division. Their new laboratory will combine technical and mechanical expertise and rely on the knowledge of two doctors, Dr. Lelio Leoncini who specializes in physical medicine and rehabilitation, and a neurosurgeon Villiam Dallolio.

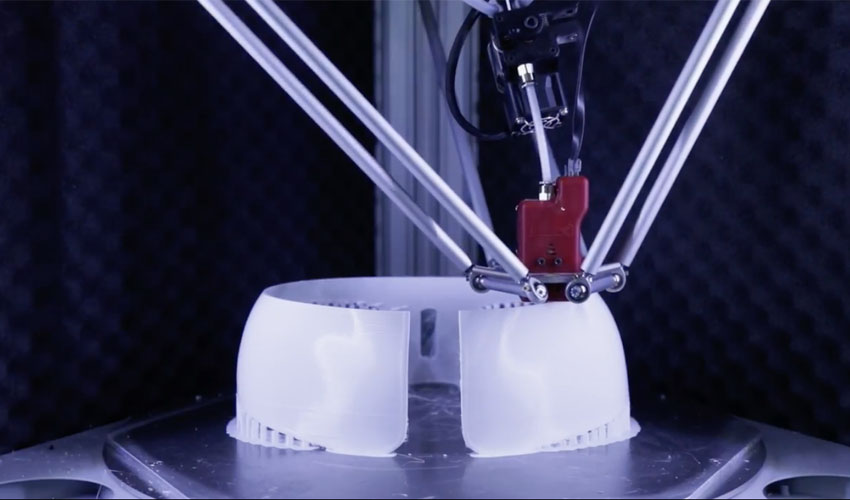

The scanner (3) digitizes the patient; the software (4) makes it possible to prepare the 3D file; the two 3D printers (1-2) make it possible to manufacture the medical device; the filaments (5) are chosen by WASP with attention

A laboratory for 3D printing medical devices

The digital orthopedic laboratory has a body scanner designed from a large frame in which four lenses are positioned. The patients are placed in the center of the frame to scan their upper body. This is a process that only takes 6 seconds. The data can be used to create corsets, for example, for those who suffer from scoliosis. A smaller hand scanner can be used for hands and feet. The scanned data is then used to 3D print orthopedic insoles and wrist orthoses. The laboratory also includes two large-scale 3D printers, the 2040 TURBO2, and the 4070 Industrial, to directly manufacture medical devices.

The manufacturing of personalized medical devices could be greatly facilitated thanks to this new laboratory, like the digital platform developed by Mecuris. The idea is to make these solutions more accessible and offer fully adapted offers, whether for the feet, hands or back.

In addition to opening the lab, WASP says it has donated two 3D printers to the University of Damascus in Syria so that it can create its own medical solutions. In a war context, many suffer from the loss of limbs and getting an affordable prosthesis is sometimes hard to come by. These 3D printers could be a solution for designing low-cost medical devices. Massimo Moretti, CEO, and Founder of WASP concludes: “Our goal is to develop processes, machines, and supplies to deliver superior service, even in developing regions. In Syria, we will create a link between the medical data of specialists in our territory and the needs of a war-affected population.”

You can find more information on WASP’s official website.

What do you think of this digital orthopedic laboratory? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!