An Origami 3D-Printed Ventilation System to Fight COVID-19

At Simon Fraser University in Canada, a team of researchers led by Professor Kim Woo Soo developed a 3D-printed ventilation system to fight COVID-19. Drawing inspiration from the art of Japanese folding, better known as origami, the team was able to reduce the weight, size, and production cost of the portable system, which is made up of 95% of 3D-printed parts. This portable ventilation system could be of use to any patient who may need an easily transportable device outside of hospitals, such as patients in isolated rural areas, countries where access to health care is more difficult, or healthcare establishments that are treating a higher than normal volume of patients.

As you know, the recent global health crisis has highlighted the weaknesses of our supply chains, especially in the medical sector. Additive manufacturing has been able to provide short and medium-term answers to allow rapid access to care solutions such as respiratory masks, valves, or even some ventilation systems. As mandates are eased and daily activities have a semblance of normalcy, COVID-19 is still present and the medical sector remains on alert. In preparation for a possible new wave, researchers at Simon Fraser University have designed a ventilation system that is easier to transport and less expensive to produce.

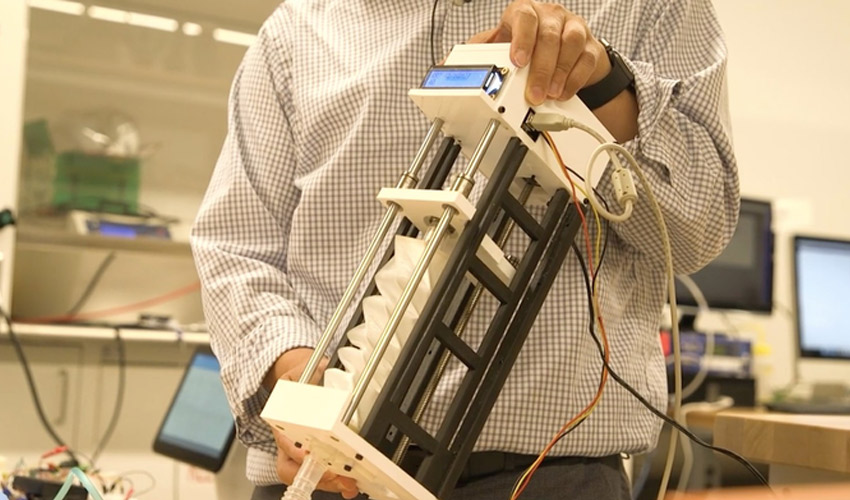

This system was designed to provide patients with assisted breathing. The ventilator’s design incorporates a 3D-printed tube in origami, considerably reducing the size of the machine while optimizing its mechanical resistance. Kim Woo Soo specifies: “In our origami portable fan, more than 95% of the components can be 3D printed, which is why it is really cost-effective. Other portable devices can cost over $2,000, but our 3D-printed fan can be produced for around $200.”

Due in part to the use of ultralight materials, the system weighs only 4.5 kilograms. The team did not specify which process was used, but we imagine that it is an extrusion technology. In any case, this device could well help patients who do not have access to a nearby hospital setting. Kim and his team have also started research on the manufacture of 3D-printed origami dry electrodes that could detect and monitor physiological signals such as temperature, heart rate, or muscle movement. You can find more information HERE.

*Thumbnail Photo Credits: Simon Fraser University

What do you think of this 3D-printed ventilation system? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!