Orgasol® PA12, a Material Offering Repeatability, Sustainability and Cost-Effectiveness to 3D printing users

As the additive manufacturing market continues to evolve, innovation is essential to unlocking new possibilities. This means constantly improving machines and software, as well as developing higher-performance materials capable of meeting the growing demands of users. Something to which French specialty material leader Arkema is paying particular attention: for several years now, it has been developing different types of materials for additive manufacturing. Its latest launch is Orgasol® PA12, a polyamide powder designed for powder bed fusion (PBF) technologies. It not only reduces printing costs thanks to its high recyclability, but also offers a better surface finish for more aesthetically pleasing parts. But what are the key features of this new material developed by Arkema? What can it bring to the 3D printing market?

To demonstrate the full potential of Orgasol® PA12 powder, comparative studies with conventional PA12 have already been carried out. These sought to better understand the material’s behavior over time through the evaluation of several criteria. Take viscosity, for example. Conventional PA12 powders exhibit significant polycondensation behavior, particularly at high temperatures, with substantial increases in viscosity. Orgasol® PA12, on the other hand, shows no change in viscosity.

Characteristics of Orgasol® PA12 Powder

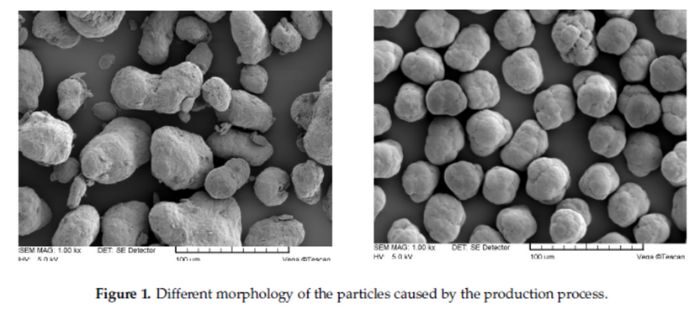

Let’s take a closer look at the properties of the material developed by Arkema. Arkema’s aim was to develop a high-performance material that would meet manufacturers’ requirements in terms of sustainability, recyclability, cost and surface quality. For the latter point, note that Orgasol® PA12 powders are highly homogeneous and spherical in shape, with a narrow size distribution of around 40 µm. This results in smoother parts with improved surface aesthetics; particularly important when producing parts where visual and tactile quality are paramount.

In addition to this improved surface finish, users of the material will be able to expect greater profitability. Pierre Gonnetan, Global Market Manager at Arkema, explains, “One of the most compelling benefits of Orgasol® PA12 is its ability to significantly reduce variable material costs, and therefore costs per part produced, thanks to the powder’s high recyclability and optimized part nesting per job.” Indeed, depending on the technology used (HP Multi Jet Fusion or Selective Laser Sintering) and the density of the parts per build, it is possible to reduce variable material costs by up to 50%, and total printing costs by up to 40%!

Pierre continues, “These reductions translate into substantial savings and increased production efficiency, making Orgasol® PA12 an economically attractive option for parts manufacturers.”

Orgasol® PA12 offers improved surface aesthetics for the final parts (photo credits: Arkema)

Sustainability and Repeatability

Orgasol® PA12 powders also make it possible to take a new step forward in sustainable development with 3D printing. The material makes a zero-waste solution possible, thanks to its enhanced recyclability in the machine. This recycling rate can be as high as 90%, depending on the process and machine used, thus minimizing waste and contributing to a more sustainable production process.

Furthermore, Orgasol® PA12 retains its properties impressively over time, guaranteeing consistent performance over many production cycles. This stability is crucial for applications requiring high precision and reliability.

Ultimately, Arkema’s new powder offers numerous advantages in terms of cost-effectiveness, surface quality, sustainability and repeatability. Meaning that users of PBF processes will be able to rely on an innovative, high-performance material to imagine the applications of tomorrow. Click HERE to find out more.

What do you think of Arkema’s new powder? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo: Courtesy of HP