MIT Spinout Uses 3D Printing to Create More Effective COVID-19 Nasal Swabs

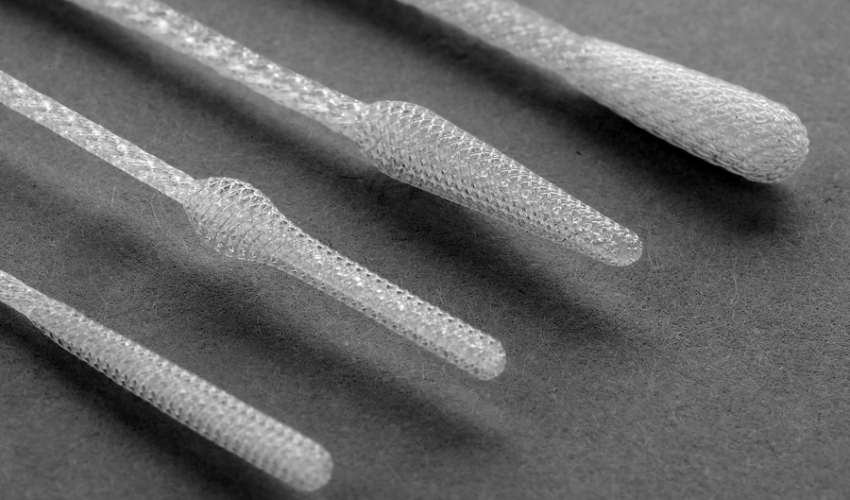

Using a continuous manufacturing approach, the MIT spinout was able to scale up its printer production according to the increasing demand for its product. OPT Industries has now supplied more than 800,000 swabs to several different health care and at-home testing organizations, playing a crucial role in meeting hospitals shortages to ensure that testing can continue. “It’s very meaningful to be part of this effort,” Ou says. “It also feels particularly good because we’ve been developing materials with hairlike structures for a long time, so it’s like, ‘Aha, our expertise finally put to use!’”. He continues, “When it came to the swabs we thought, ‘Hey, that’s a great fit! Swabs need to be soft, flexible, the structures on the tip need to be very intricate. That’s what we do.”

Not only have these swabs played a crucial role in aiding the supply shortage crisis, but they also provide a better solution to traditionally manufactured swabs. In fact, the tiny woven lattices that Ou developed during his time at MIT allow OPT’s swabs to absorb and release more fluid than their conventionally manufactured counterparts, and thus provide more accurate tests. OPT’s swabs release 20 times the amount of bacteria for testing, increasing the sensitivity of the tests. “We’re trying to be like [the multinational products company] 3M in additive manufacturing,” Ou says. “Everyone knows 3M because they have a lot of different products that are essential to daily life. That’s the model we’re going after. We have other medical and cosmetic products under development — the swab is just the beginning.”

While the company are currently working on ways to increase their facility’s production capacity, at the moment they are able to produce 80’000 swabs a day. OPT Industries are currently working on developing other medical sampling devices for testing other diseases which would benefit from high bacterial collection rate offered by their technology. Next month the company will move to a new facility which will combine its lab and production teams, which Ou hopes will allow them to accelerate the cycle from product ideation to design, prototype, optimization, and production.

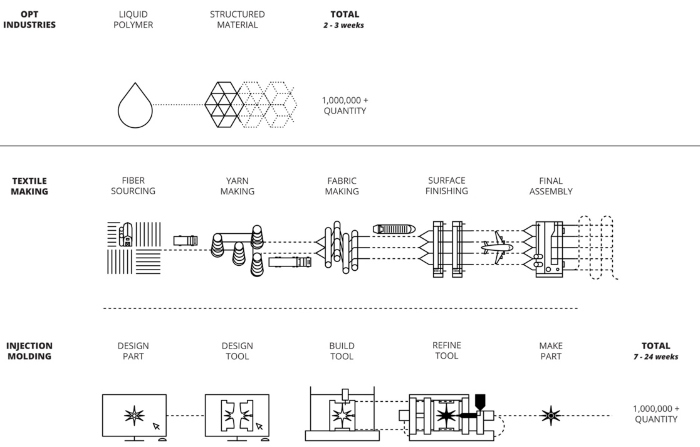

OPT Industries offers a faster production time than other conventional methods of manufacturing materials. (Photo Credit: OPT Industries)

You can find out more about OPT Industries’ projects on their website. What do you think about OPT’s nasal swabs? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

*Cover credit: OPT Industries