OECHSLER Rethinks Ski Mask Design with 3D printing

Increasingly, companies are seeing the benefits of using 3D printing in sports. Another company has entered the ring. German company OECHSLER, which specializes in the development and manufacture of high-tech products and systems, recently turned its attention to the design and production of ski masks using 3D printing. After realizing that the masks are designed with 13 different parts, the teams sought to manufacture a mask in one go, increasing its strength and durability. They turned to additive manufacturing to make this happen. They were able to produce a 3D printed ski mask from TPU.

Even if ski lifts are closed as we start moving into warmer weather, let’s not forget all the joys associated with the mountain, skiing, snowboarding … but also the possible difficulties. Who has never found himself with a missing glove, a too tight boot or an ill-fitting mask? Masks in particular can be difficult, most of us have experienced the foam of the mask that comes off with time, the fog that forms, the lack of visibility. It is to limit these types of problems that the German group has rethought the design of a ski mask to print it in 3D.

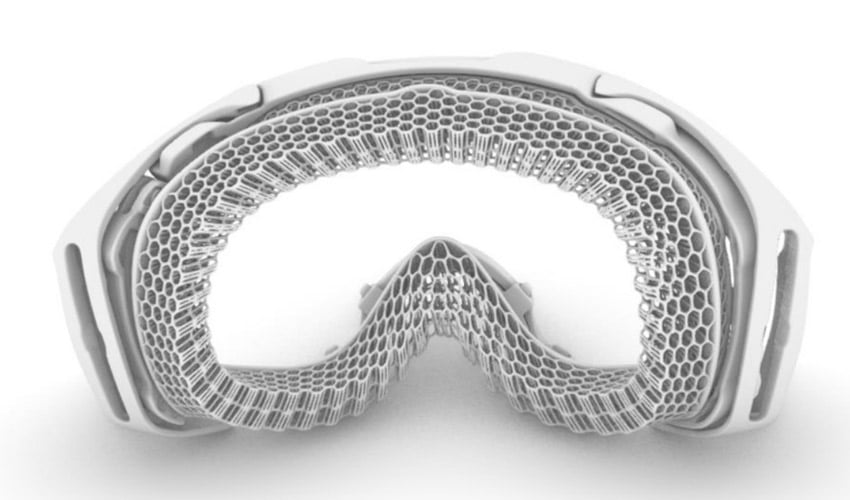

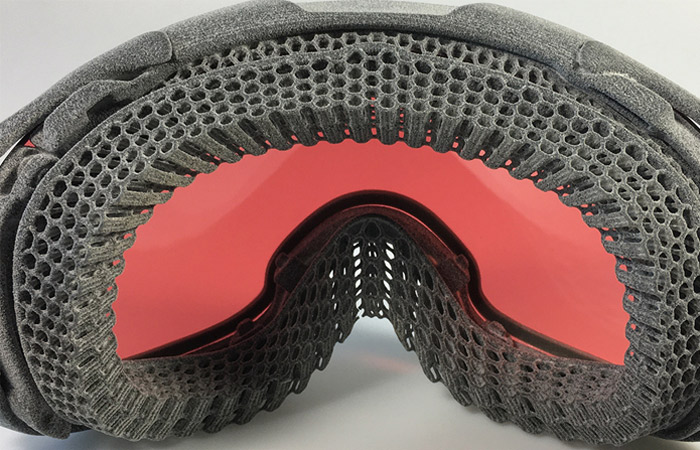

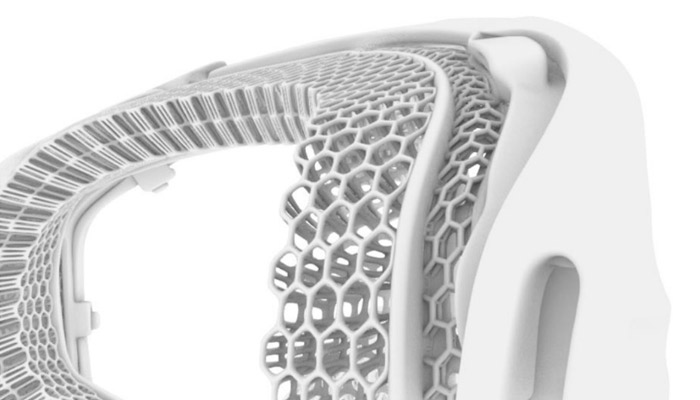

The number of mask parts has been considerably reduced (photo credits: OECHSLER)

The process of creating the ski mask

One of the benefits of additive manufacturing is that it can reduce the assembly phase of a product by creating the desired part in one go. The ski masks would be made up of 13 parts and according to OECHSLER, this “leads to a higher failure potential during production, higher risk of product failure, and ultimately higher costs.” In just one week, the company was able to come up with a completely different design, going from 13 components to one. To do this, it started by taking apart a traditional ski mask to understand how it was made. The outer frame, for example, incorporates layers of internal foam glued together. Soon, the teams wanted to eliminate this production step and replace the polyurethane foam with a 3D printed lattice structure.

All the components of the ski mask were scanned by CT scan and then reconstructed in a software in order to generate a 3D printing file for the different parts, be it the frame or the lattice structure. This one should not be too thin at the risk of breaking, not ensuring the kinematics. TPU was chosen as the printing material because of its flexibility. It was essential to replicate the comfort offered by the classic foam.

The teams imagined a lattice structure instead of foam (photo credits: OECHSLER)

The team explains that they conducted several trials and tests: “The first prints were too stiff so that the handles were not flexible enough. Contrary to the initial assumption, this was not caused by the print file but by the post-processing steps in production. The lattice structure needed a different and more intense cleaning of the lattice structures to remove more of the printing residue. Even though optimizing the print file has been quite fast, the adjustment of the post-processing to increase the flexibility of the lattice structure was challenging.”

In the end, the 3D printed ski mask should both be more comfortable and more effective in terms of cushioning in case of an accident. On the production side, the German company specifies that costs are reduced since assembly steps no longer exist and that additive manufacturing offers greater agility – the product can be designed in just a few days. In any case, hopefully one day soon it will be possible to test out this 3D printed ski mask! In the meantime, you can find more information HERE.

What do you think of this 3D printed ski mask? Let us know in a comment below or on our Linkedin, Facebook and Twitter pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

let us see the entire ski mask