NREL Advances Sustainable Marine Energy Technology With 3D Printing

As the global demand for a reduced reliance on fossil fuels intensifies, harnessing clean and renewable energy sources has become an increasingly crucial subject. Among these emerging solutions, marine energy, which focuses on capturing power from waves, tides, and currents, holds immense potential in the search for sustainable energy solutions. Recently, researchers have begun to explore a revolutionary approach to develop this technology further through additive manufacturing. A unique collaboration between the National Renewable Energy Laboratory (NREL) and the Pacific Northwest National Laboratory is shedding light on the promising intersection of marine energy and the innovative technology of 3D printing.

For over two years, NREL scientists have been exploring the practical applications of additive manufacturing to enhance marine energy technologies, focusing on metal 3D printing. Unlike traditional plastic printing, which proved inadequate for oceanic applications, researchers swiftly pivoted to metals for their strength and durability. These characteristics proved extremely beneficial in components crucial for the functioning of key energy producers in marine energy, such as offshore wind farms.

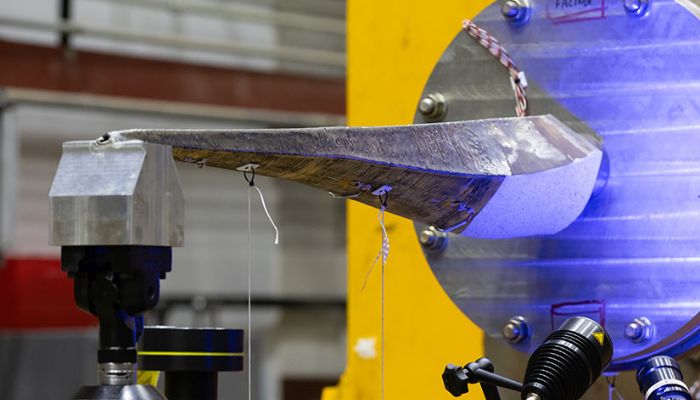

3D printed stainless steel tidal turbine spar.

Emphasizing the importance of robust materials for ocean environments, Paul Murdy, a mechanical engineer at NREL leading the marine energy additive manufacturing study, stated, “In the very beginning, we quickly figured out that typical plastic additive manufacturing processes wouldn’t produce strong enough components to handle ocean forces. It became apparent that it would be impossible to design this structure without using metals.”

Stainless steel, known for its corrosion resistance, emerged as a top choice for creating tidal turbine spars, the backbone of turbine blades used in wind farms. Leveraging laser metal deposition, researchers aim to create durable components capable of withstanding strong air currents and ocean forces.

Back in the lab, tidal turbine spar components face rigorous tests to validate their design and durability. Load and fatigue testing ensure the printed spars can handle real-world conditions. Pushing the spars beyond their limits, exceeding design specs by 50%, helps researchers understand how they’ll perform and last in the long run. With 3D printing technology, the components are better suited to handle these extreme conditions. “We’ve opened a really unique design space through 3D printing. This project has demonstrated that additive manufacturing has the potential to produce very strong, stiff structures that will be good for marine energy.” Murdy stated.

The benefits of 3D printing within this industry extend beyond the design room. The technology offers numerous advantages, including reduced manufacturing timelines and costs. Additionally, the ability to customize components with intricate details allows for efficient rapid prototyping, enabling the quick testing of designs and alterations of the turbine spar components.

The 3D printed stainless steel tidal turbine spar undergoes testing to ensure it can withstand ocean forces.

With these benefits, it is projected that increasing the number of prototypes available would allow extensive testing and iterative design processes, aiding researchers in pinpointing the most promising technologies for blue economy sectors like aquaculture or microgrids in coastal communities. “For specific communities in particular places, marine energy could be a game changer.” explained Miguel González-Montijo, a designer of the tidal spar component. “For example, my home, Puerto Rico, could benefit from an upgraded energy grid that incorporates renewable energy technologies like marine hydrokinetic energy. These technologies could help many small towns build energy resilience and independence while delivering locally sourced, renewable power.”

What do you think about the NREL’s exploration of 3D printing within the marine energy industry? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: NREL