nonplanar.xyz provides the tools to use the z axis correctly in FDM printing

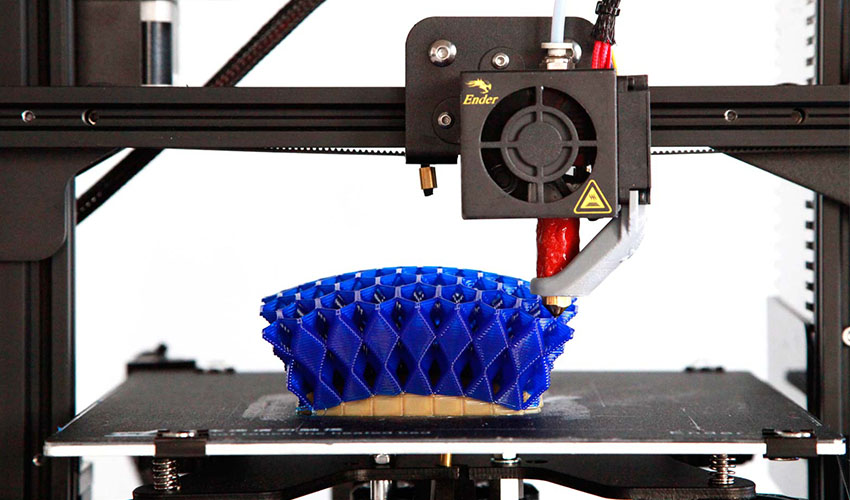

Whilst a 3D printer has movement for 3 axis, x, y and z, it pretty much never uses them at the same time. Usually only x and y movements of the 3D printer nozzle are used to form the geometry of the part being 3D printed. In other words, 2D planes are stacked up to create a 3D shape, instead of creating geometry with true 3D tool paths. Using the z axis correctly can open FDM 3D printing to many more possibilities. This is what Gabriel Boutin, founder of Kupol Inc. – the company behind 3D printed bike helmets – is seeking to change with the launch of nonplanar.xyz. The startup is essentially a platform that will allow you to leverage the benefits of non planar 3D printing. It provides elongated nozzles for this purpose, as well as print-ready g-codes and tutorials on custom programming for your desktop 3D printer. So what exactly are the benefits of non planar 3D printing? We spoke to Gabriel Boutin to learn more.

3DN: Can you present yourself and your relationship with 3D printing?

I am passionate about progress and self-learning. Since I have discovered industrial design and all the possibilities around software tools, I kept on pushing my own limits to become a better creator. I started my journey as an entrepreneur in 2007 by offering services to companies in Canada. I have been involved in the development of many bicycle helmets and it made me realize that it was about time for this industry to be reinvented. I had an epiphany during the summer of 2016 regarding 3D printing and its unique ability to create complex structures susceptible of absorbing energy. I immediately formulated a method for creating a helmet and I registered for an international patent. I tried my chance on Kickstarter during the summer of 2018 but I missed the target. I had to think further about the keys of success to make it happen. I moved to Montreal and I have assembled a team of four highly skilled companies to enter the NFL helmet challenge at the end of 2019. We intend to win this challenge in 2021 by presenting a fully 3D printed flexible liner that will exceed the performance of all helmets available today.

3DN: Why did you decide to create nonplanar.xyz?

Nonplanar.xyz came out of the process of looking for the right manufacturing process that will allow 3D printing to become an affordable solution for the masses. To be honest, I have disregarded FDM for many years, thinking it did not have the capability of producing high quality finished products. I was wrong. For years, we were satisfied with the typical layers produced by the variety of lookalike slicers without realizing that the z-axis was unexploited. It was simply a matter of pushing the predefined limits to produce the desired result. Nonplanar.xyz is my way of sharing what I have discovered and to make it accessible to all makers.

3DN: What benefits does it offer to those that use FDM technology?

By design, FDM uses raw thermoplastics and therefore is able of high strength along the flow of the layers. Of course, the adhesion between the layers is the weaker point but is it a problem if we can curve those layers? When we look at nature we see perfectly efficient anisotropic structures everywhere. Trees, leaves, bones, feathers and more are all anisotropic curved alignments of strong and lightweight leaving structures.

In order to ”leave the surface” you have to let go of the idea of the magic bullet. Each object has its own truth and therefore its own ”program”. By program I mean sequence of lines. I am not a programmer and I don’t want to become one. It is a process that everyone can learn within a few days of studying.

3DN: Who do you expect will use nonplanar.xyz’s nozzles and resources?

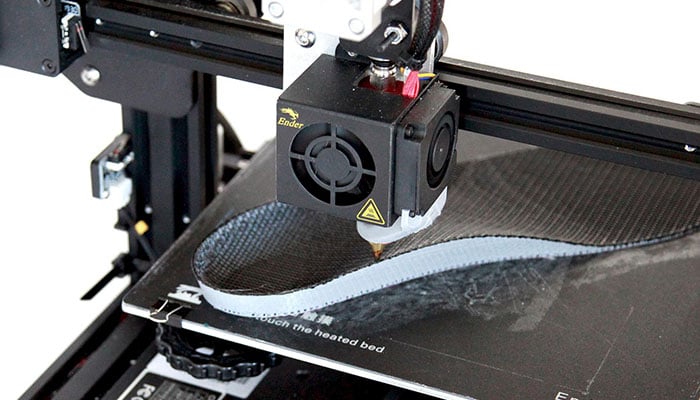

Creating value is easier when you use affordable printers. I chose the Creality products for myself because of their very low price and good reputation. Using a tool under $300 brings a lot of satisfaction when you see the result that comes out of it. According to your goal, you can easily modify your setup and extrude soft filaments and expand dramatically the universe of possibilities. The setup I propose to use is accessible to the hobbyist as well as the professionals. Of course, the nozzle is the most important part of the equation because it allows to avoid collision with the printhead while performing curved surfaces. We suggest you explore different diameters to find the best matches for each application you which to create.

The nozzle is the most important part of the equation because it allows to avoid collision with the printhead while performing curved surfaces

3DN: What is your take on the FDM 3D printing market?

I can only do predictions on what I can control. To me, the future is bright for FDM/FFF. It is a proven technology that has a lot to reveal yet.

3DN: What are the plans for nonplanar.xyz in the future?

Nonplanar.xyz will be the place where all makers go to find tools to participate to the the non-planar revolution. We will offer whatever fits that vision.

3DN: Any last words for our readers?

Layers are meant to fly!

You can find more information on nonplanar.xyz HERE.

What do you think of nonplanar.xyz? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

It’s sells nozzle you can buy elsewhere cheaper and software that only works with complex software that costs more than the Creality machine they talk of. Not a good place to join.