Nomad Prototypes Unveils Resin-Based 3D Printed Drone

In aviation, the use of 3D printed drones has already revolutionized our perception of aerial possibilities. These devices, the result of a fusion between 3D printing and modern aviation, offer unprecedented flexibility and adaptability. We’ve already seen a number of examples, such as drones designed to extinguish fires, assist in construction and repair, or even carry out military missions.

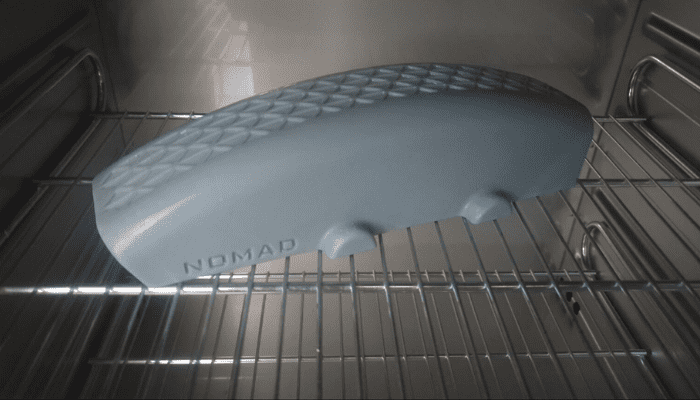

Nomad Prototypes, a company based in the United Arab Emirates, has introduced a resin-based 3D printed drone as an alternative to thermoplastic models. This drone, powered by a high-performance battery, has a flight time of 37 minutes without a payload. Nomad Prototypes is focused on researching new 3D printing methods with the goal of producing the world’s largest 3D printed drone.

Nomad Prototypes highlights a challenge encountered in 3D drone printing using FDM technology – the inherent issue of part strength variance due to directional printing. Simply put, this results in weaker points between layers. While suitable for smaller drones, scalability becomes an issue, as increased structural thickness amplifies weight without proportionate strength gains compared to traditional manufacturing methods. Over the past decade, the company has extensively explored various 3D printing techniques such as FDM, SLA, SLS, and Multi Jet Fusion. In their endeavor to construct the world’s largest 3D-printed plastic drone, Nomad Prototypes strategically opts for a combination of SLA and pellet extrusion methods, leveraging their distinct advantages for optimal results.

The company’s first drones are small, multi-rotor drones made with Liqcreate StrongX resin. This photopolymer resin undergoes both UV and thermal curing, making it stronger. The company is moving ahead with its next model, the second in its series, which will be a modular drone that can be transformed into a fixed-wing aircraft with vertical take-off and landing. It will be made from a tough, flexible resin, with wings optimized to be both thin and strong. The company claims that this optimization is not feasible with FDM technology.

If all goes to plan, Nomad plans to create a drone with a 3.2-meter wingspan using FGF (Fused Granular Fabrication) 3D printing technology. This larger drone will have a maximum take-off weight of around 15 kg, and will be designed to fly at reduced speeds to minimize stress on its structure. “Some of these new pellets have incredibly high carbon fiber loads, reaching up to 50% carbon fiber. This would be impossible to print in filament format, as the filament is so stiff, it would snap as soon as it reaches the extruder,” explains Phillip Keane, founder of Nomad Prototypes.

In the long term, the company believes it will be able to 3D print a drone capable of carrying a person. It sees the expansion of 3D-printed fixed-wing drones as crucial to achieving this goal. “It’s certainly possible to 3D print a wing out of metal that could support the weight of a human being in flight, although it would be extremely expensive to do so at present,” Keane explained.

What do you think of this 3D printed drone? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Phillip Keane