New Nitrides for Mass Production: The C1000 FLEXMATIC Reaches an Industrial Milestone

Ceramic additive manufacturing is no longer limited to prototyping and is gradually establishing itself as an industrial production solution. Designed to meet stringent performance and reliability requirements, today’s ceramic AM processes now leverage advanced materials suited for demanding environments.

In this context, 3DCeram Sinto has announced that its C1000 FLEXMATIC is compatible with aluminum nitride (AlN) and silicon nitride (Si₃N₄), two technical ceramics recognized for their performance and used in particular in aerospace, semiconductors, and optics.

Based on the SLA process, the C1000 FLEXMATIC combines semi-automation and artificial intelligence to support mass production. Its print volume of 320 × 320 × 200 mm allows parts of various sizes to be manufactured with consistent precision. CERIA AI automatically generates optimized printing parameters, ensuring repeatable quality and reduced downtime, making the machine a reliable production tool for manufacturers.

Great Material Compatibility

The C1000 FLEXMATIC prints aluminum nitride and silicon nitride, two high-value-added technical ceramics for demanding industries. It should be noted that both have very interesting mechanical and chemical properties.

Aluminum nitride (AlN) combines high thermal conductivity, reaching approximately 180 W/m·K, with excellent electrical insulation, making it a benchmark material for advanced thermal management applications. Its low thermal expansion (≈ 3 × 10⁻⁶ K⁻¹) ensures high dimensional stability, even under severe thermal stresses.

These properties enable the design of components capable of efficiently dissipating heat while maintaining their geometric precision, a key advantage for heat sinks, electronic substrates, and equipment for the semiconductor industry, particularly when additive manufacturing is used to integrate optimized and functional geometries.

Silicon nitride (Si₃N₄) is characterized by excellent wear and corrosion resistance, combined with high hardness and mechanical strength (up to ≈ 750 MPa in bending).

These characteristics make it a material particularly suited to structural parts for aerospace and defense, where mechanical strength, durability, and reliability in extreme conditions are essential.

Widening the Field of Possibilities

Technical ceramics combined with additive manufacturing make it possible to fully exploit the geometric freedom offered by the process, while optimizing key parameters such as mass, functional integration, and the thermo-mechanical performance of parts. This approach paves the way for more sustainable and higher-performance applications capable of meeting demanding industrial specifications.

In the semiconductor industry, a representative use case is heat sinks, whose function is to ensure that heat generated during processes is removed efficiently. These components must combine mechanical stability, high thermal conductivity, and resistance to plasma environments. The use of ceramic additive manufacturing, particularly with aluminum nitride (AlN), makes it possible to design optimized geometries—such as internal channels or functionalized surfaces—that are difficult to achieve using conventional processes, directly improving heat dissipation efficiency.

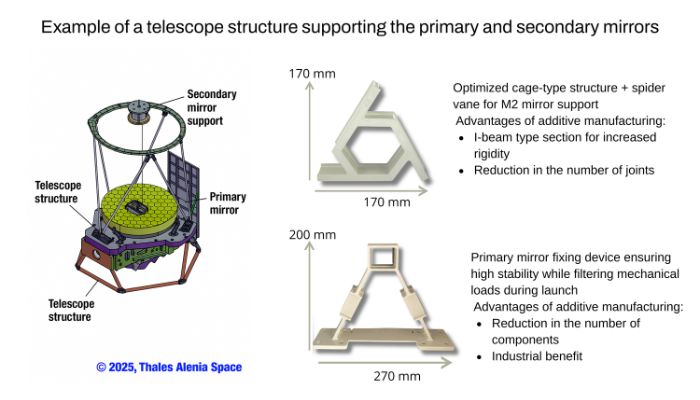

Applications of 3D-printed silicon nitride (Si₃N₄) also illustrate the value of this approach in the fields of optics and aerospace. Additive manufacturing is used to produce structural components for telescopes, including mirror mounts, whose architecture has been redesigned to combine weight reduction, increased rigidity, and mechanical stability. These optimized designs facilitate system integration while improving overall performance.

3D-printed silicon nitride is particularly popular in optics and aerospace (Photo credits: Thales Alenia Space)

These examples are just a fraction of what is possible with ceramic additive manufacturing, particularly with 3DCeram Sinto’s semi-automated industrial solution. The company concludes: “The transition from prototyping to production in the field of ceramic AM is gradual, but the direction is clear. Manufacturers are looking for machines that offer repeatability, materials that meet demanding specifications, and workflows that comply with industrial practices. By integrating AI-guided process control, semi-automation, and advanced nitrides, the C1000 FLEXMATIC is positioning itself as a platform for this transition.”

Would you like to learn more about this platform and the possibilities of ceramic additive manufacturing? Contact the 3DCeram team HERE.

Have you used ceramic additive manufacturing? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*Cover Photo Credits: 3DCeram Sinto