Nikon to Implement Space Strategy Fund at Japan Aerospace Exploration Agency

Nikon Corporation (Nikon), known for its digital manufacturing and advanced selective laser melting (SLM) solutions, announced last week that it was selected as one of the organizations to implement the Space Strategy Fund (SSF) by the Japan Aerospace Exploration Agency (JAXA). Nikon will work on the technology development theme “Innovative technology for lightweight, high-performance, and lower cost space transportation systems” in the SSF open call for FY2024. Nikon’s mission is to develop and demonstrate additive manufacturing for low-cost, short-lead-time precision parts for space applications, using its Nikon SLM Solutions NXG XII 600, organic R&D and new facilities in Japan.

Each organization participating in the SSF will lead in its own area of technological expertise, leveraging research from Japanese universities and companies. Specifically, they will use Japan’s first large-scale metal 3D additive manufacturing system platform, a system that Nikon claims “will capture the global market.”

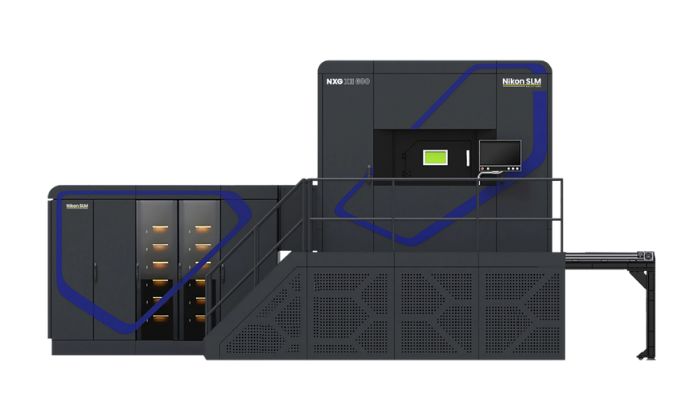

Nikon’s SLM Solutions NXG XII 600 that it will use for the SSF project

The technology development theme’s purpose is to establish a base technology that achieves innovations in molding processes and enhanced parts. Along with that, they aim to implement wider applications of metal additive manufacturing for large-scale structures, as well as parts for space transportation systems. The project description also mentions achieving innovation using carbon fiber-reinforced plastics for wider applications.

One of the project’s goals is to develop a metal additive manufacturing base technology for large and precise space parts like rocket engines. Why additive manufacturing? Nikon acquired metal 3D printing giant SLM Solutions in 2023, along with its expertise in selective laser melting (SLM) technology. SLM, which is a powder-bed fusion process, can fabricate parts with complex geometries and advanced properties. To do SLM, metallic powder is spread over a build plate and then melted with a focused laser beam in an inert atmosphere. After a layer is scanned, the build plate is lowered, and the next powder layer is transferred onto the build plate. This fresh layer of powder is scanned, and the build plate moves down again. This process continues until the final part is realized. SLM can achieve metal parts with extremely high resolution, precision and accuracy, so the manufacturing method can meet the demanding needs of aerospace applications.

Just as the project’s title states, AM is also capable of achieving low-cost and lightweight parts, ideal for aerospace, where weight makes all the difference. That is why so many organizations, including NASA and the United States Department of Defense are 3D printing parts for rockets. Now, JAXA is making similar efforts, and we will have to wait and see how Nikon’s work impacts spacecraft production. To learn more about Nikon’s participation in the SSF, click here.

What do you think of Nikon’s project to build large parts for rockets? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! If you are looking for more 3D printing in aerospace & defense content, check out our dedicated page HERE. Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Image: A part for aerospace 3D printed by Nikon. All image credits: Nikon