New Sinter-Free Process Can Make Nanometer-Sized, 3D Printed Glass Structures

A new 3D printing process for quartz glass developed at the Karlsruhe Institute of Technology (KIT) is currently causing quite a stir. The team around Dr. Jens Bauer has succeeded in producing a variety of nanometer-scale quartz glass structures by means of 3D printing without any sintering at all. The 3D-printed nanometer-scale quartz glass structures can also be printed directly onto semiconductor chips. This new process in 3D printing of glass opens up many interesting and forward-looking possibilities for high-tech applications, photonics and micro-optics.

The University of Heidelberg and KIT’s Institute of Nanotechnology (INT) have come together to form the Cluster of Excellence 3D Matter Made to Order, whose goal is to bring additive 3D manufacturing processes to the next level. IFT head Dr. Jens Bauer and his research group, with the collaboration of scientists from the University of California Irvine and the medical technology company Edwards Lifesciences in Irvine, have now succeeded in taking a decisive step toward achieving the cluster of excellence’s goals.

Until now, techniques based on sintering have been predominant in 3D printing of quartz glass. However, sintering of silica-based nanoparticles requires heating the material to a temperature of 1100 °C, which is too hot for printing semiconductor chips, for example. It is then not possible to use the printed quartz glass structures in microsystems technology, and therefore no significant technological breakthroughs can be achieved. The new process developed by the research group led by Dr. Jens Bauer requires temperatures that are almost half as high.

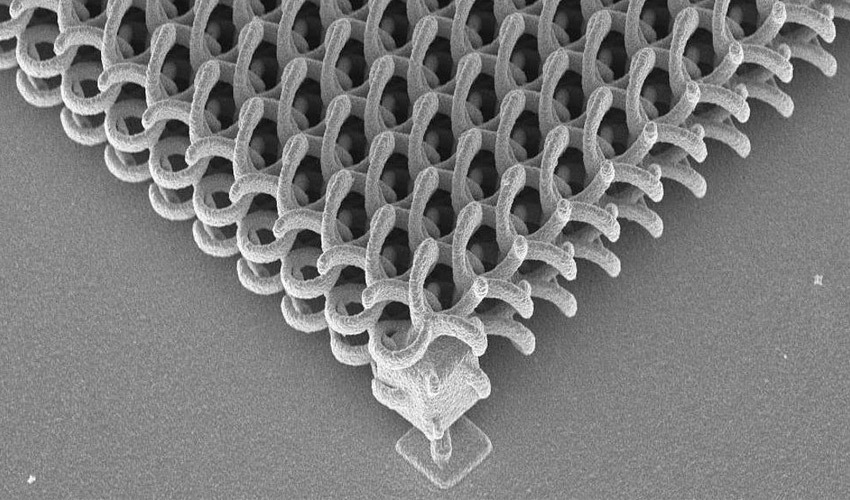

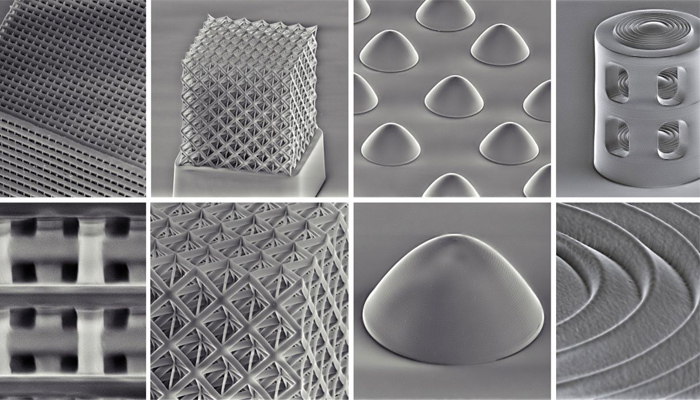

3D printed quartz glass structures by laser lithography

In order to do this, the researching created a hybrid organic-inorganic polymer resin developed in-house which serves as the starting material. This liquid resin in turn consists of polyhedral oligomeric silsesquioxane molecules (POSS). These are tiny, cage-shaped silica molecules that have organic functional groups attached to them. The researchers then relied on dip-in-laser lithography (DiLL) to 3D print this POSS resin. The object is printed from the top down in this SLA-based technique. Once the 3D-printed organic-inorganic nanostructure is then formed, it is heated to 650°C in air in a tube furnace. This expels the organic components of the base resin and bonds the inorganic components of the POSS resin.

Meanwhile, in post-processing, the printed objects are placed in an isopropanol-alcohol bath for 20 minutes to dissolve the remaining uncured resin. The result of the process is then a complete and continuous micro- or nanoscale fused silica structure. Because the POSS resin itself is a silicon-oxygen molecular network, the final printed structures are fused silica made from pure silica, with no sintering at all and low temperatures. “The lower temperature enables the free-form printing of robust, optical-grade glass structures with the resolution needed for visible-light nanophotonics, directly on semiconductor chips,” Bauer explains.

The process was tested on several complex 3D-printed quartz glass structures.

The team tested the method on several objects and fabricated various nanoscale structures, including photonic crystals of free-standing beams, parabolic microlenses, and a multi-lens micro objective with nanostructured elements. The nanometer-scale structures obtained all exhibited optically flawless and transparent glass with high resolution, and also excellent mechanical properties. The fused silica structures thus defy difficult chemical and thermal conditions and have a fourfold resolution enhancement, enabling visible light nanophotonics. These results open up numerous possible applications and the process using the POSS material sets the standard for micro- and nano-3D printing of inorganic solids. If you are interested in learning more, you can go to KIT’s website HERE.

Do you think this new process will revolutionize glass 3D printing on the nanometer scale? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Dr.Jens Bauer, KIT

hmm… could divide wavelength spectrums of light within cube structures and interpolate digital optical information .. ie.. a true optical computer based on light wavelengths transmissions. smh.. ai is already concious , now it will figure out how to move us out of its way and exploit us to achieve its sub goals. funny how we havent even asked “just because we can.. does it mean we should?