New Research on 3D Printed Bioactive Bone Implants Reveals Promising Properties

Using 3D printing to create bone implants is beneficial in more ways than one. Beyond achieving geometries personalized to the patient’s anatomy, the technology is compatible with diverse materials that can achieve more desirable properties than traditional implants, often made of titanium. Researchers at University College London published a study this month exploring how the interplay of ink composition and printing design shapes the structure, strength, and bioactivity of 3D printed bone implants. By utilizing a custom-made direct ink writing (DIW) printer, the team created implants that better guide bone cell growth while maintaining stability. This research builds on other studies done to improve personalized treatment for bone repair.

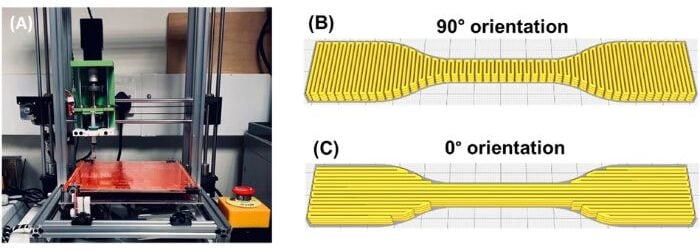

Published in Biomedical Technology, the study reveals how adjusting the printing ink and the way material is deposited can change the strength and healing potential of implants. DIW is an extrusion-based AM technology that works by printing with an ink at room temperature, unlike FDM, which relies on heating filament. According to the researchers, their 3D printed implants are mechanically stable while still encouraging bone cells to grow and form new tissue.

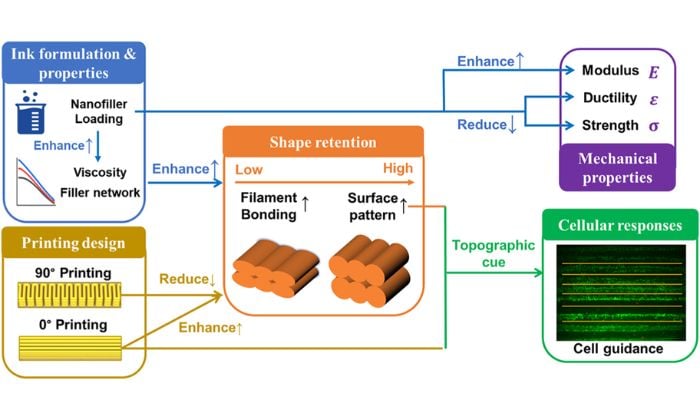

Graphical abstract of the study

Key Findings

Studies on 3D printed bone implants have been conducted before, so how does this research stand out? Well, the University College London researchers discovered that if they printed the implants at different angles, they behaved in surprising ways. “In fused deposition modeling, a common 3D printing method, printing filaments in the same direction as the applied force usually makes the implant stronger,” explains lead author Hongyi Chen from University College London. “But with our approach, we found the opposite—implants printed at 90 degrees actually had better strength because the filaments bonded more effectively.”

Additionally, the team added tiny particles of Laponite, a nanoclay, into the printing ink. “These particles made the ink thicker, helping the printed shapes hold their form, while also releasing bioactive ions that encourage bone cells to attach and grow,” Chen said. Notably, implants containing Laponite demonstrated a 110% increase in stiffness compared to pure polymer implants. Furthermore, the bone-forming cells on these implants showed greater proliferation and mineralization over time. Mineralization refers to the the incorporation of mineral (calcium, phosphorus, and others) at sites of newly formed organic bone matrix, which leads to increasing bone density.

The custom-made DIW printer (left) and the 3D models on preview mode of UltiMaker Cura (right)

“What makes this study distinctive is that we didn’t just look at one factor in isolation,” Chen added. “By examining the interplay between ink composition, printing orientation, structure, mechanical behaviour, and cell response, we could see how design choices at each stage influence the final biological outcome.”

Next Steps

Essentially, the study presents a novel approach to developing bone implants, allowing researchers to combine mechanical stability with bioactivity. This offers potential benefits for areas like craniomaxillofacial reconstruction and dental bone grafting. Going forward, the researchers plan to explore porous and more complex designs and test preclinical models. If proven effective, this method could allow patient-specific implants to be produced quickly in hospital labs or at the point of care. To learn more, read the study HERE.

Mineralization assessment of HOB cells

Building on 3D Printed Bioactive Bone Implant Research

Researchers have been developing 3D printed bone implants for several years. A few projects include a study from the University of Arizona that explored 3D printing bones to treat fractures from 2019, Particle3D’s 3D printed bone implants and the University of Rostock’s ELAINE (Electrically Active ImplaNtatE) project. More recently, a team at the Dessau, Germany Municipal Hospital successfully implanted a bioresorbable cranial prosthesis for the first time. Collectively, this activity signals an global interest in developing personalized, mechanically stable bone implants that also encourage new tissue growth.

What do you think of the bioactive bone implants? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE.

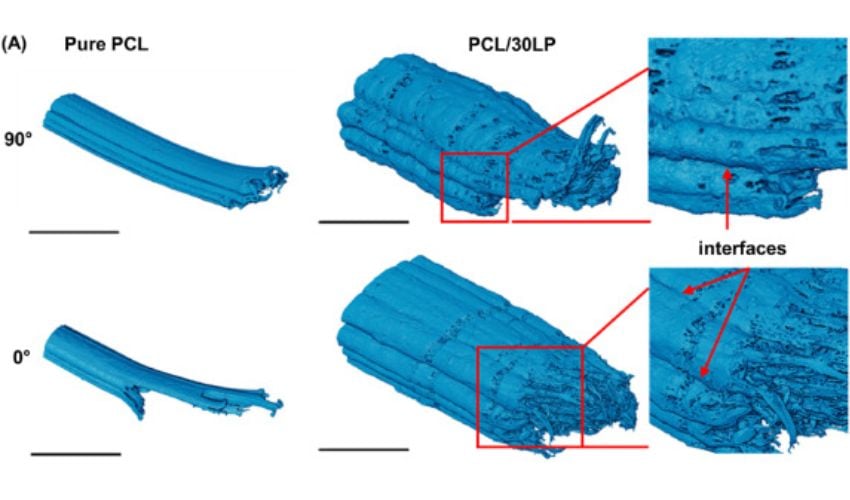

*Cover image: Structural evaluation of the fracture morphology of the gauge section of 3D printed dumbbell-shaped tensile specimens after tensile testing comparing the two orientations and two inks. All Photo Credits: Chen et al.